Foldable display module

A technology for displaying modules and folding areas, which is applied in the direction of identifying devices, instruments, and other household appliances, etc., can solve the problems of high material and manufacturing costs of foldable devices, and achieve the effect of reducing material and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

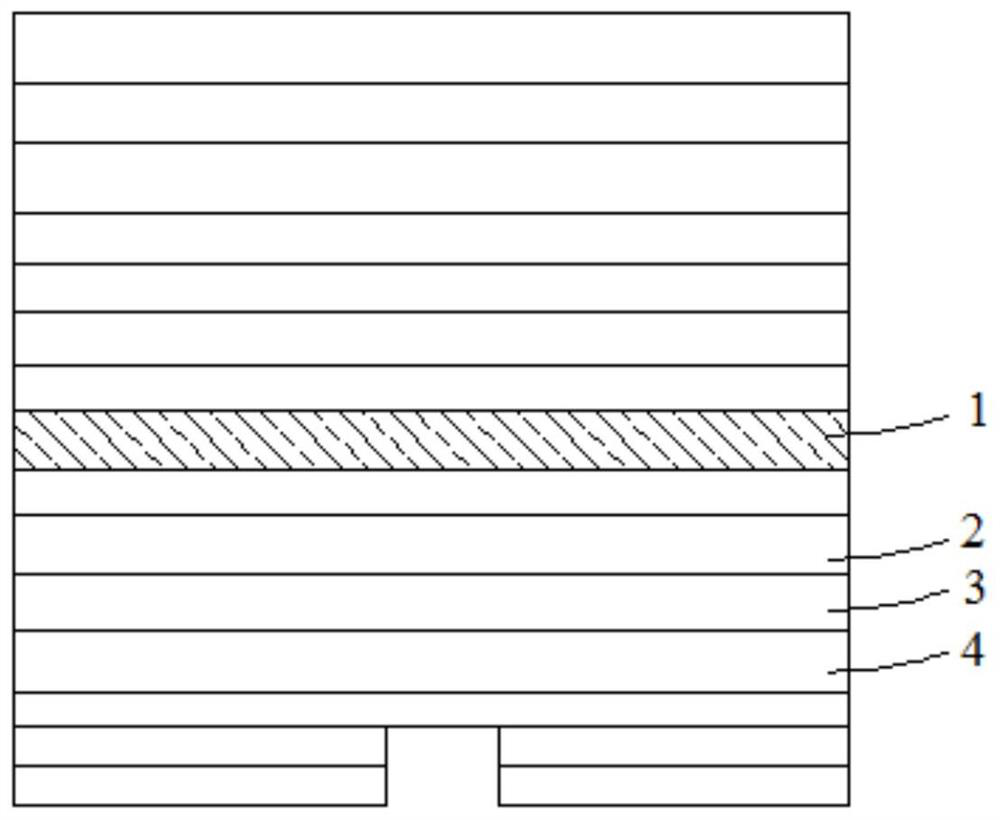

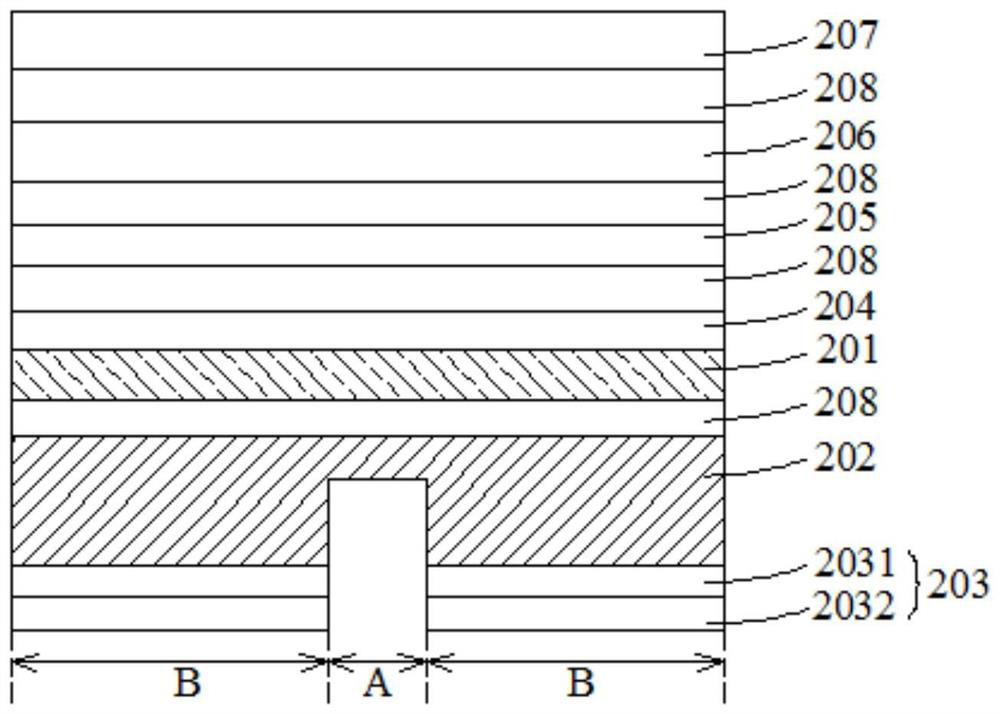

[0033] Such as figure 2 As shown, it is a schematic structural diagram of the foldable display module provided in Embodiment 1 of the present application. The foldable display module includes a flexible display panel 201, the front of the flexible display panel 201 is a display surface, and the back of the flexible display panel 201 is a non-display surface. The non-display surface side of the flexible display panel 201 is sequentially provided with a flexible supporting layer 202 and a heat dissipation layer 203 from top to bottom, and the display surface side of the flexible display panel 201 is sequentially provided with a touch panel from bottom to top. 204 , a polarizer 205 , a flexible cover 206 , and a protective film 207 . Moreover, two adjacent film layers are bonded to each other through the adhesive material layer 208 .

[0034] In this embodiment, the thickness of the flexible supporting layer 202 may be 300 microns. Specifically, the thickness of the flexible ...

Embodiment 2

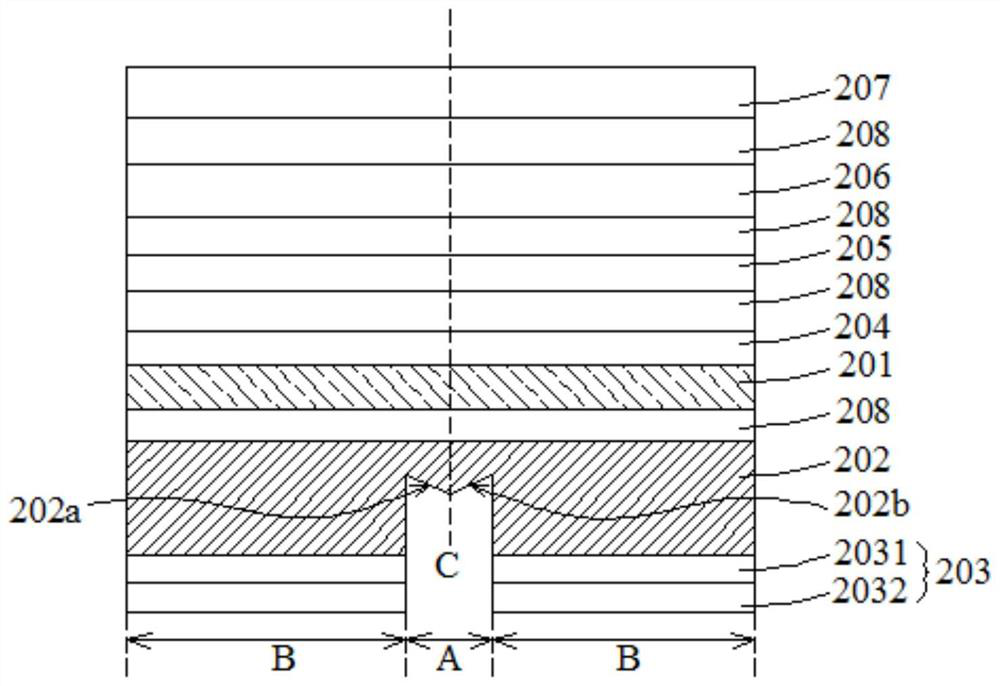

[0050] Such as image 3 As shown, it is a schematic structural diagram of the foldable display module provided in Embodiment 2 of the present application. The structure of the foldable display module in this embodiment is the same / similar to the structure of the foldable display module in the first embodiment above, the difference is that in this embodiment, the flexible supporting layer 202 in the folding area A is thinned. The way is to facilitate the patterned thinning of folding, that is, the flexible supporting layer 202 of the folding area A is provided with non-equal thickness, and the thickness of the flexible supporting layer 202 corresponding to the folding area A is determined by the The middle part of the folding area A decreases toward both sides.

[0051] Specifically, the foldable display module is folded inwardly. The part of the flexible supporting layer 202 corresponding to the folding area A and the rest are continuous film layers, and the part of the flex...

Embodiment 3

[0055] Such as Figure 4 As shown, it is a schematic structural diagram of the foldable display module provided in the third embodiment of the present application. The structure of the foldable display module in this embodiment is the same / similar to the structure of the foldable display module in the first embodiment above, the difference is that in this embodiment, the flexible supporting layer 202 in the folding area A is thinned. The way is to facilitate patterned thinning of the folding, that is, the thickness of the flexible supporting layer 202 corresponding to the folding area A decreases from the middle of the folding area A to both sides.

[0056] Specifically, the part of the flexible supporting layer 202 corresponding to the folding area A and the rest are continuous film layers, and the part of the flexible supporting layer 202 corresponding to the folding area A includes a first arc surface 202c and a second arc surface 202c. surface 202d, the first arc surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com