Pretreatment device for mixing straw auxiliary materials

A pretreatment device and pretreatment technology, applied in crop processors, feed, applications, etc., can solve the problems of soil staining, inconvenient use, complex structure, etc., and achieve the effect of improving stability, strengthening stability, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

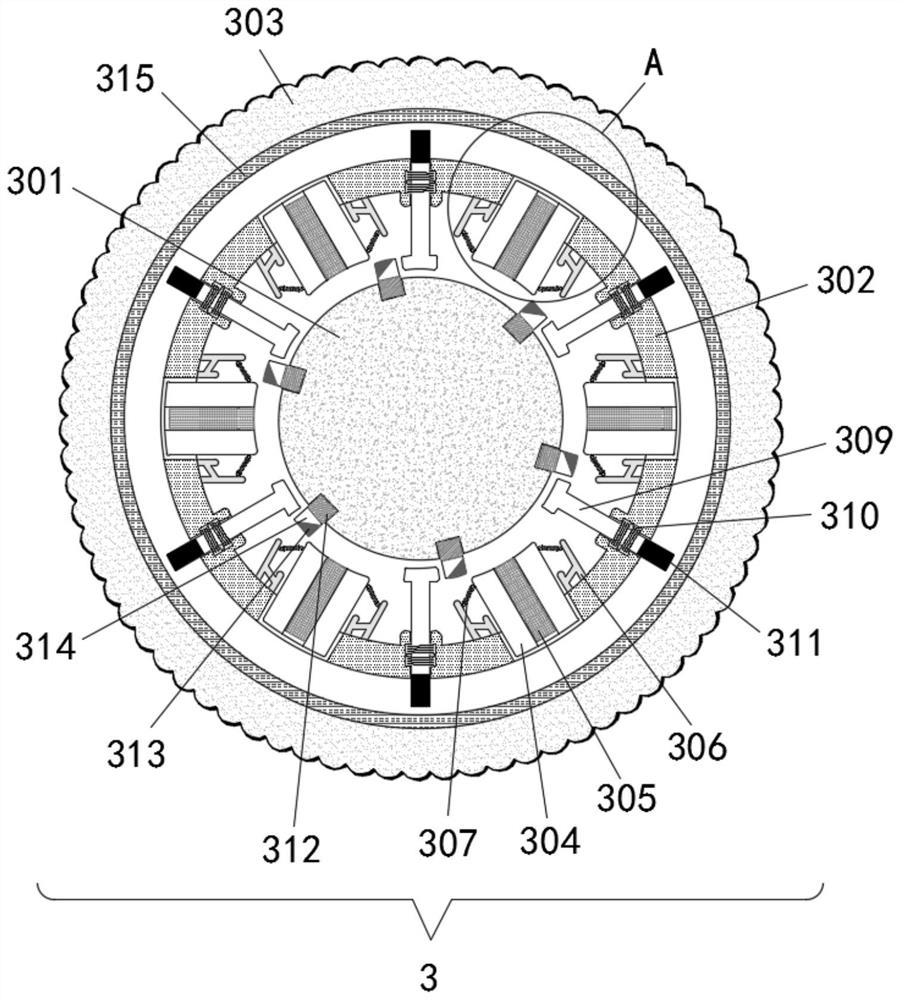

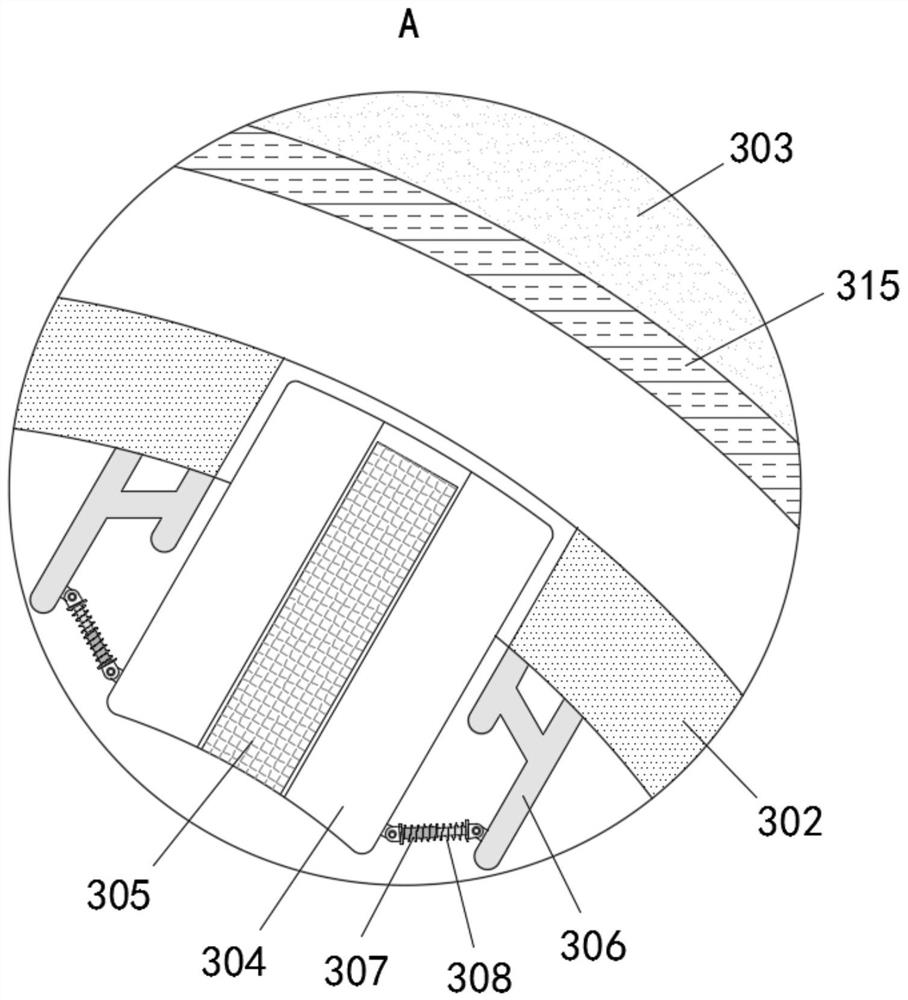

[0032] as attached figure 1 to attach Figure 7 Shown:

[0033] The present invention provides a pretreatment device for mixing straw auxiliary materials, which comprises a mixer main body 1, a pretreatment bin 2 is fixedly installed on the top of the mixer main body 1, and a feeding trough 4 is fixedly connected to the top of the pretreatment bin 2. The outer side of the processing chamber 2 is provided with a ventilation hole 5, and a filter screen 6 is installed inside the ventilation hole 5, and an exhaust mechanism 7 corresponding to the ventilation hole 5 is installed on the mixer main body 1, and the inside of the pretreatment chamber 2 is rotated and installed with a symmetrical arrangement. The pressure roller part 3;

[0034] The pressure roller part 3 comprises a squeeze roller 303, which is rotatably installed in the inside of the pretreatment chamber 2, and the inside of the squeeze roller 303 is fixedly inserted with an intermediate ring 302, and the inside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com