Outboard pre-operation platform of LNG ship enclosure system

A technology for operating platforms and LNG ships, which is applied in the field of pre-operation platforms outside the cabin of the LNG ship containment system, can solve problems such as limited space in LNG tanks, material bumps, hidden quality problems, etc., and achieve humanized overall layout, high construction fluency, and The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

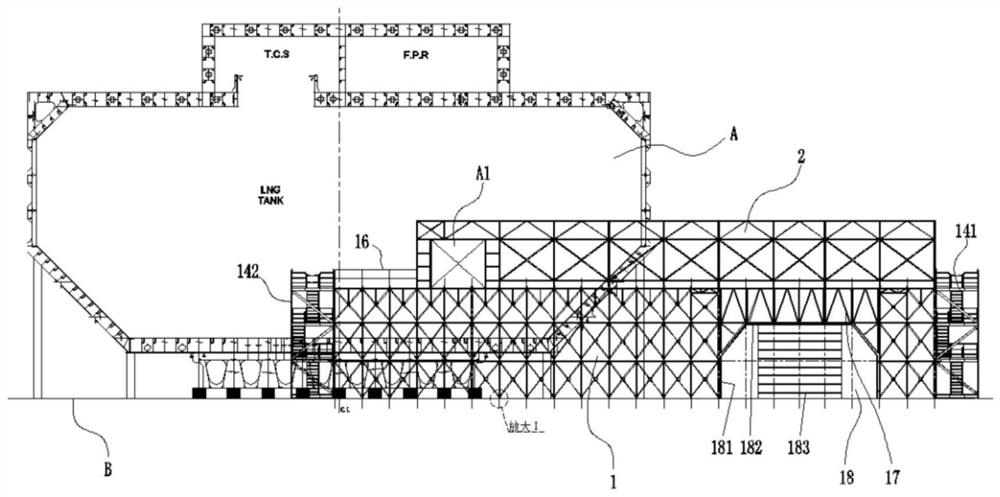

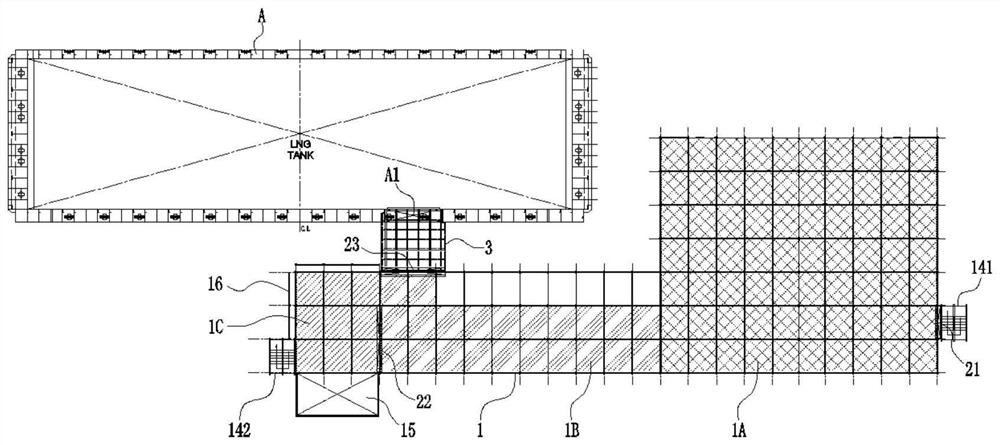

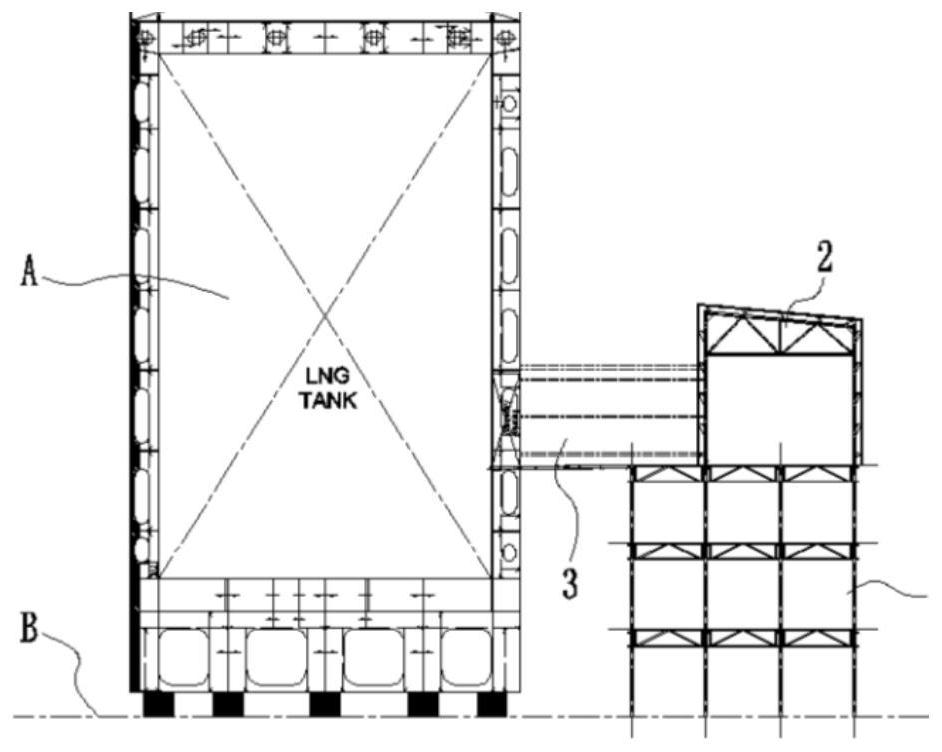

[0050] Such as Figure 1-15 As shown, this embodiment discloses an LNG pre-operation platform outside the cabin of a membrane-type containment system. The pre-operation platform includes a material storage and transportation platform 1 , a constant temperature and humidity room 2 , and a cabin entry platform 3 .

[0051]The material storage and transportation platform 1 is equipped with platform ladders 141 , 142 and a material lifting device 15 .

[0052] The top of the material storage and transportation platform 1 is divided into three functional areas: storage work area 1A, channel area 1B, and material loading area 1C. The uniform load of storage work area 1A is not less than 250Kg / m2, the area is not less than 300m2, and the Not less than 10m, the uniform load of passage area 1B is not less than 300Kg / m2, the passage width is not less than 4m, the uniform load of feeding area 1C is not less than 300Kg / m2, and the length and width are not less than 4m.

[0053] The stora...

Embodiment 2

[0065] Such as Figure 1-15 As shown, the present embodiment discloses a pre-operation method for LNG outside the cabin of a membrane-type containment system, which specifically includes the following steps:

[0066] S1, build a material storage and transportation platform 1 outside the LNG tank A facing the temporary process hole A1, and the height difference between the top of the material storage and transportation platform 1 and the lower opening of the temporary process hole A1 is not greater than 100mm;

[0067] S2, building a constant temperature and humidity room 2 based on the material storage and transportation platform 1;

[0068] S3, installing the entry platform 3 based on the material storage and transportation platform 1;

[0069] S4, install an air-conditioning system in the constant temperature and humidity room 2 and adjust the temperature and humidity to the required working environment to form a pre-operation platform for the enclosure system;

[0070] S5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com