Multi-filter-element water purification device

A water purification device and filter element technology, applied in multi-stage water treatment, filtration treatment, water/sewage treatment, etc., can solve the problems of many parts, difficult assembly, increase the structure of positioning plate, etc., and meet the requirements of straightness and installation accuracy Low, reduce cleaning difficulty, improve the effect of filter element life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be further illustrated and described below through specific embodiments in conjunction with the accompanying drawings.

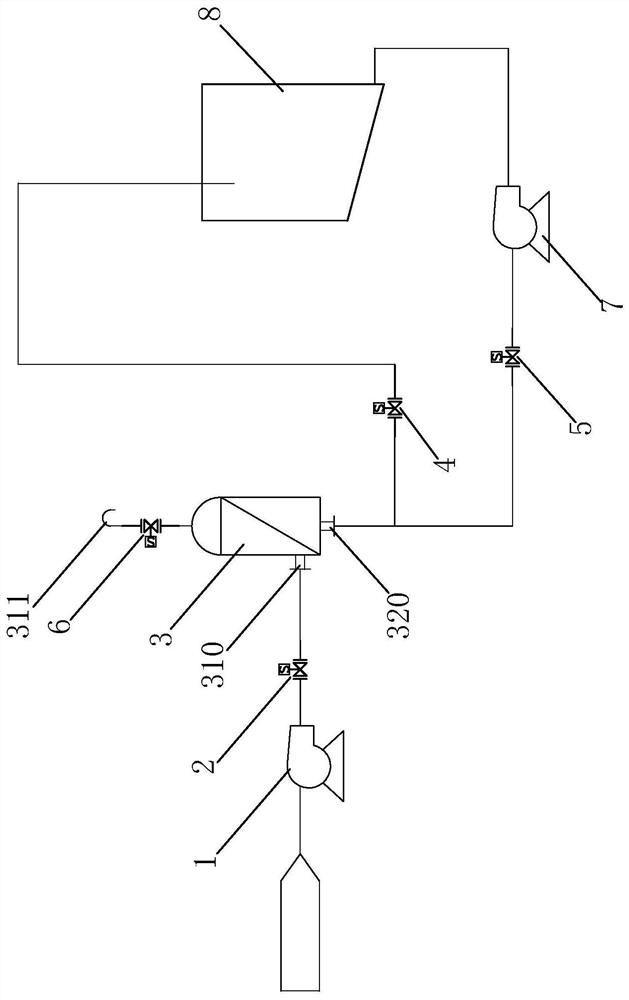

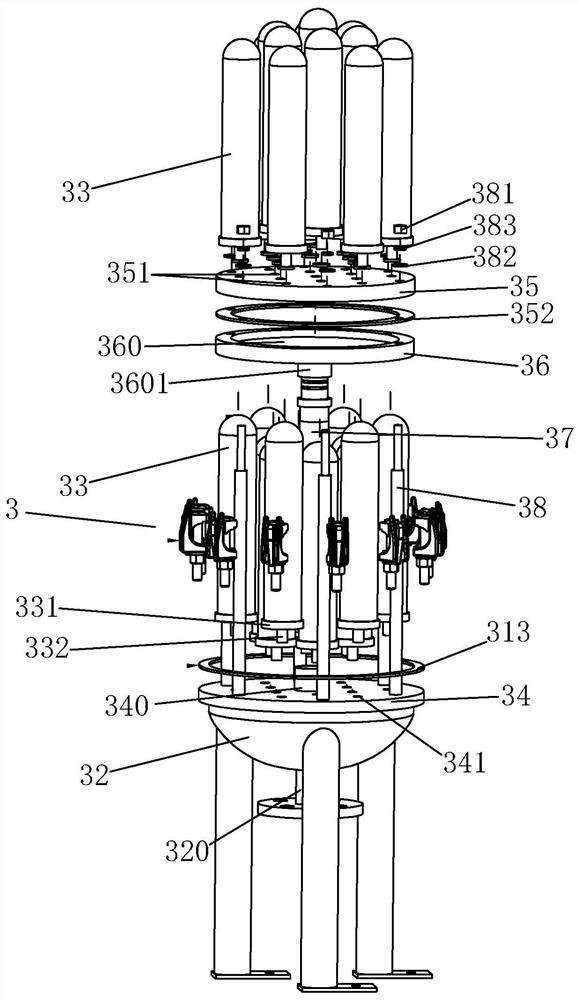

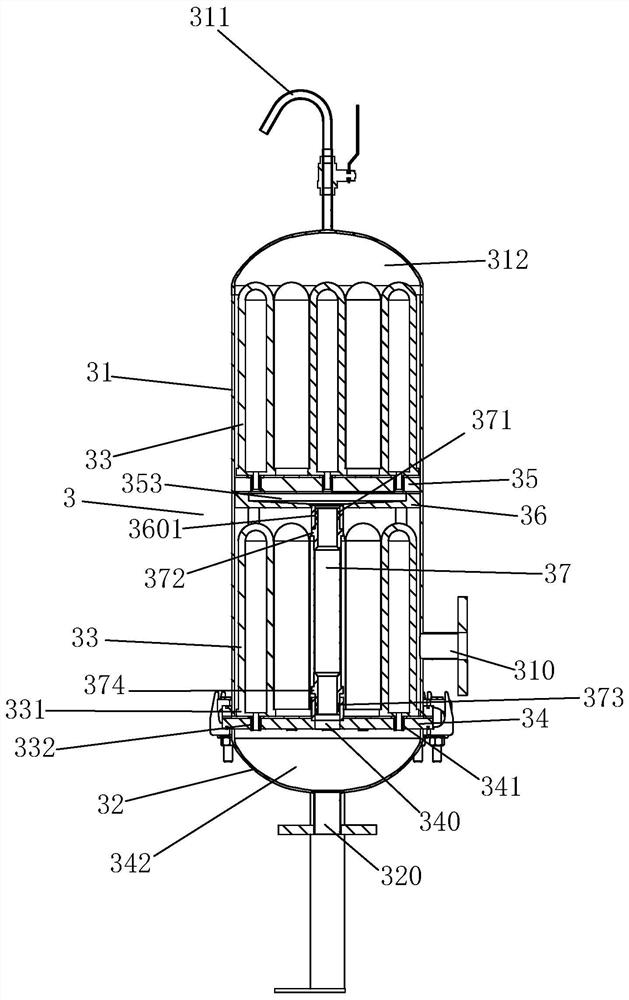

[0042] Such as figure 1 As shown, a multi-filter water purification device includes a water inlet pump 1, a water inlet solenoid valve 2, a multi-filter filter membrane unit 3, a water production solenoid valve 4, a backwash solenoid valve 5, and a sewage discharge solenoid valve 6. A backwash pump 7, a water production tank 8 and a control unit (not shown in the figure);

[0043] The external water source is connected to the water inlet pipe 310 of the multi-filter filter membrane unit 3 through the water inlet pump 1 and the water inlet solenoid valve 2 in sequence. The water production port 320 is connected to the water production tank 8 through the water production solenoid valve 4, and is connected to the water production tank 8 through the backwash solenoid valve 5 and the backwash pump 7 in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap