Washing machine

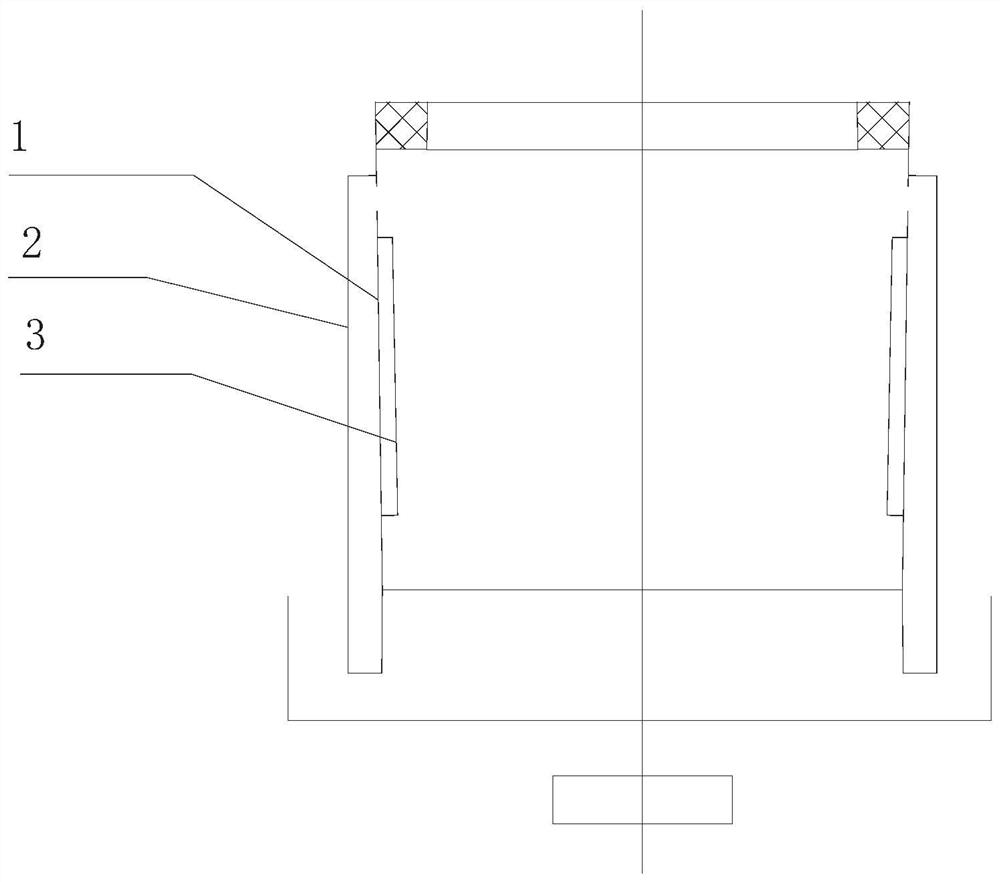

A washing machine and washing water technology, applied in the field of washing machines, can solve the problems of not realizing the fixed connection between the drainage channel and the inner tub, the difficulty of operation, and the difficult positioning structure, so as to improve the installation efficiency, avoid blind operation, and ensure the effect of dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

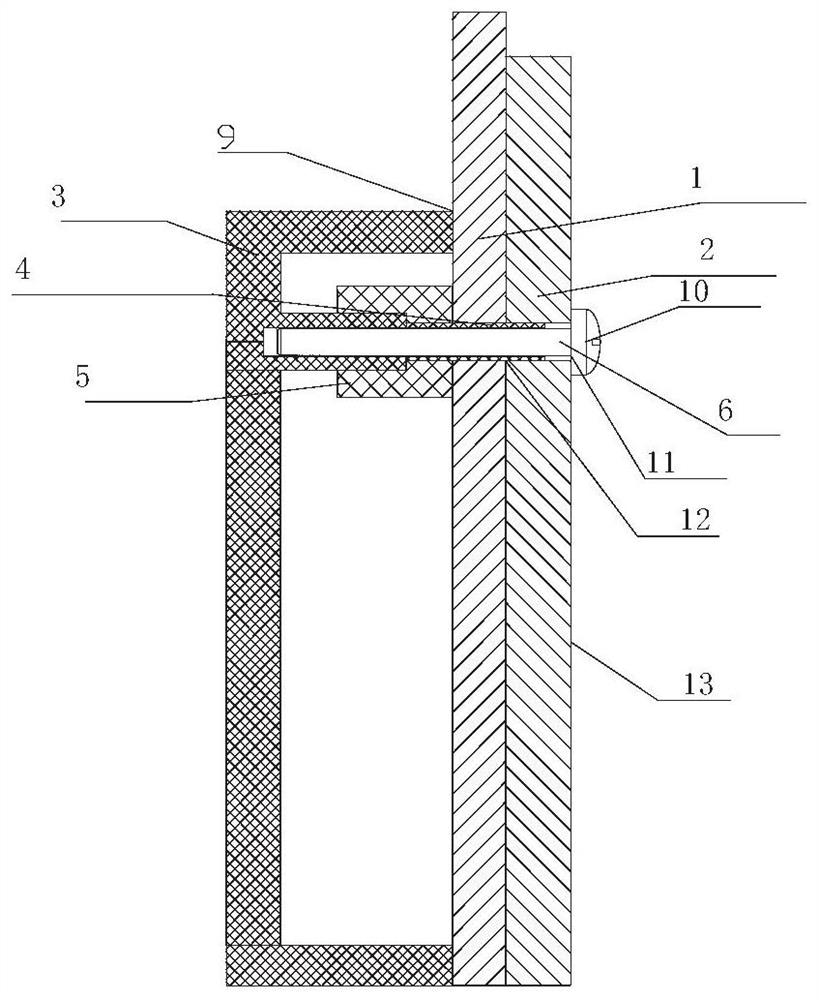

[0043] Example 1: The pre-positioning structure and the connecting piece are at the same position, that is, the connecting piece further connects the filter cover 3, the inner barrel 1, and the drainage channel 2 by connecting the pre-positioning structure. This fixing method makes the positioning and connection integrated and simplifies the installation procedure .

example 2

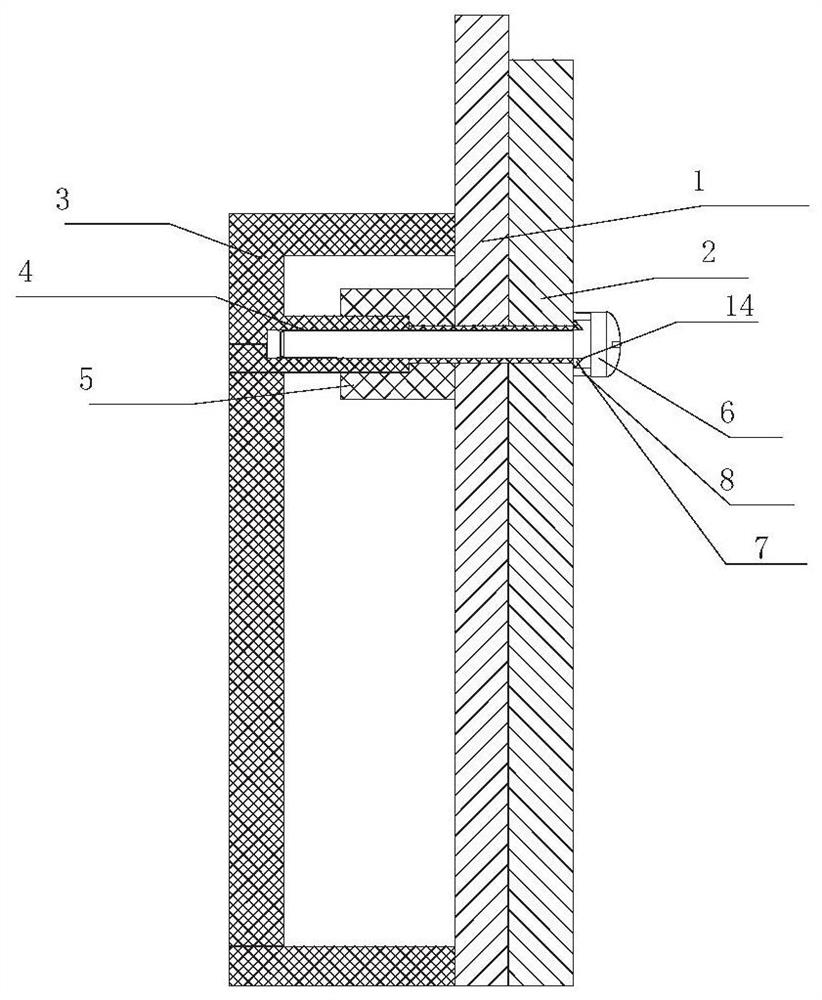

[0044] Example 2: The pre-positioning structure and the connecting piece are not in the same position, that is, the filter cover 3, the inner barrel 1, and the drainage channel 2 are fixed in position through the pre-positioning structure, and are further fixed and connected through a separate connecting piece. This method can achieve accurate positioning connect.

[0045] In the present invention, the distance from the end of the pre-positioning structure to the inner sidewall of the filter cover 3 is greater than the distance from the outer sidewall of the inner barrel 1 to the inner sidewall of the filter cover 3, and is smaller than the distance from the outer sidewall of the drainage channel 2 to the inner sidewall of the filter cover 3, preferably The top of the pre-positioning structure is 0.5-1mm lower than the outer wall of the drainage channel 2, so as to reserve the amount of compression deformation of each component when the connector is fixedly connected, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com