A Method for Optimizing the Air Compressor System in Iron and Steel Plant

A system optimization, air compressor technology, applied in the direction of mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve problems such as energy waste, compressed air pressure, flow demand changes, and the inability to grasp real-time process conditions, etc., to achieve Optimize the effect of small workload, meet real-time needs, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

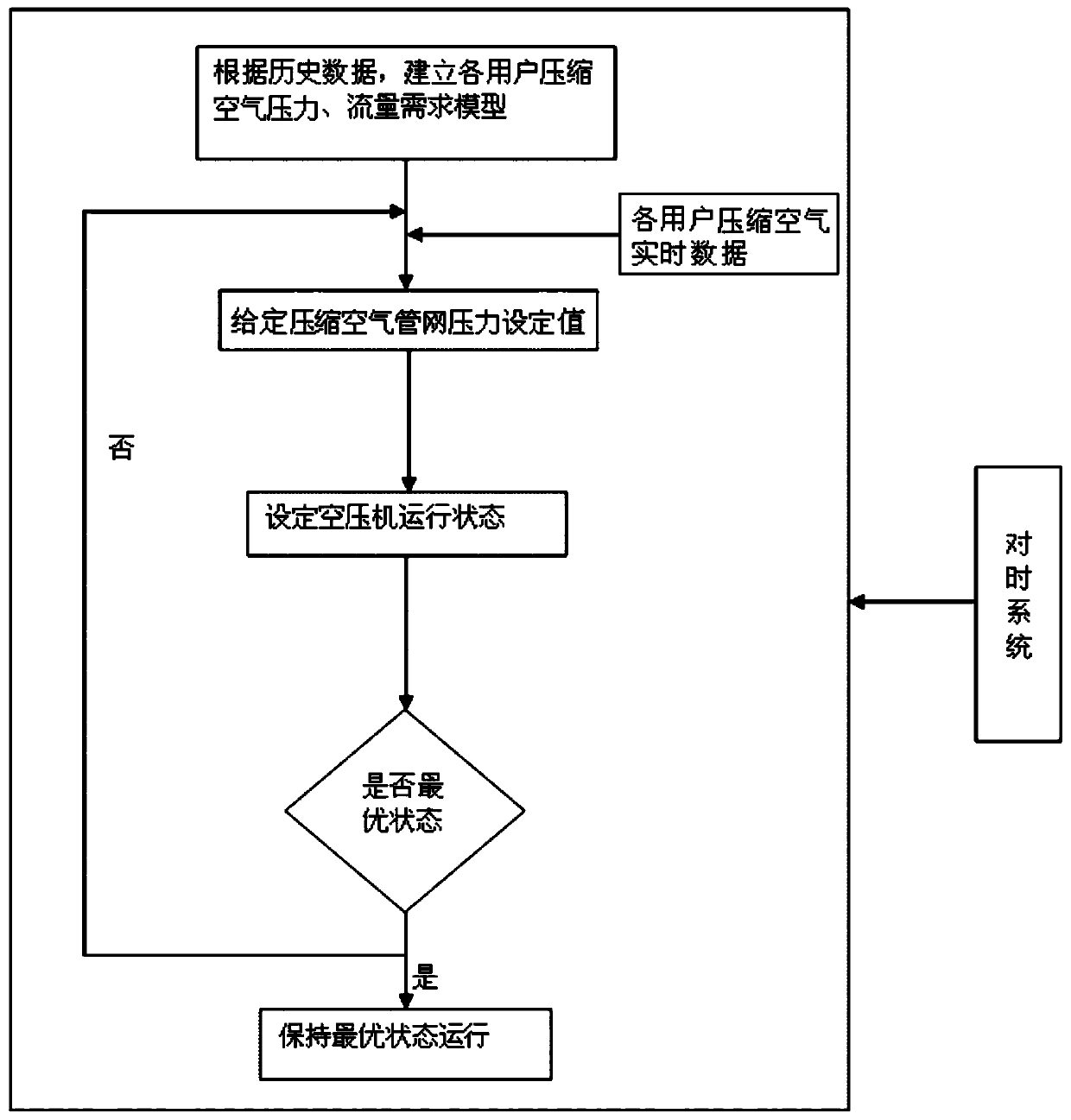

[0038] In an embodiment of the present invention, a method for optimizing the air compressor system in a steel plant is implemented through a secondary and tertiary control system composed of PLC, SCADA system and other equipment, and operates based on the unified clock signal of the steel plant, that is, using the The time synchronization system of the energy management and control center provides time service for each device and completes the unification of the clocks of each device. The historical data, real-time data, and running time of the optimization method are all based on the SNTP clock signal provided by the time synchronization system. The start, stop, and loading of the air co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com