Spliced special-shaped concrete filled steel tubular column beam-column connecting joint and construction method thereof

A special-shaped steel pipe and connection node technology, which is applied in the direction of construction and building construction, can solve the problems of uneven surface of special-shaped columns and joints, and difficulty in guaranteeing the welding quality of cold-formed areas, so as to improve welding quality, standardization and production. The effect of industrialization and convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

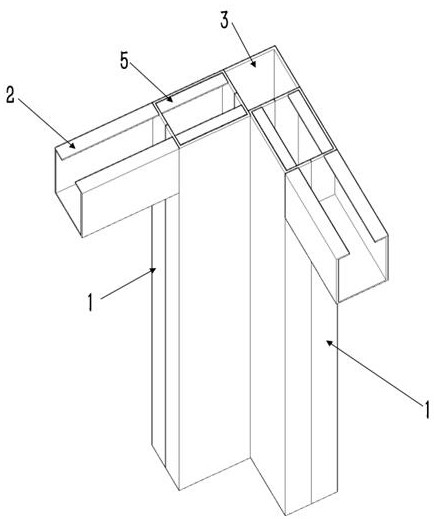

[0029] Embodiment 1: see figure 1 , a splicing special-shaped steel pipe concrete column beam-column connection node, including a plurality of steel pipe columns arranged in the vertical direction, the steel pipe columns are formed by connecting two channel steels 1, wherein the notches of the two channel steels are arranged opposite to each other, And connected to form a steel pipe column, multiple steel pipe columns are combined to form a combined special-shaped column, the two ends of the slots of the two channel steels are aligned and connected by welding, so that the two channel steels form a composite column with a rectangular tubular structure. The adjacent and parallel sides of two adjacent steel pipe columns are misplaced so that the two sides have overlapped parts, and the overlapped parts are fixedly connected together by welding.

[0030] Wherein, a plurality of steel corbels 2 perpendicular to the outer surface of the steel pipe column are also arranged on the ste...

Embodiment 2

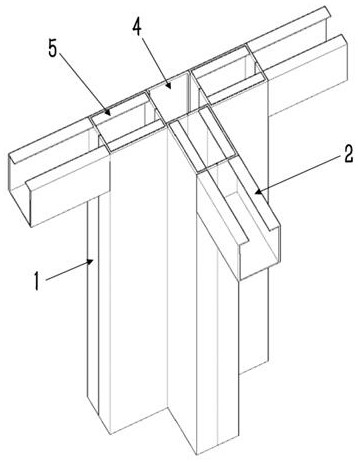

[0033] Example 2: see figure 2, the same basic structure as in Example 1, except that the combined special-shaped column includes three steel pipe columns, and the three steel pipe columns are distributed in a T shape. Two of the steel pipe columns are located on the same plane, and a gap is formed between the two steel pipe columns, and the other steel pipe column extends into the gap from one side of the gap and is fixedly connected with the two steel pipe columns. The connector is a U-shaped member 4, the open side of the U-shaped member extends into the gap from the other side of the gap, and is fixedly connected with two steel pipe columns located on the same plane, and the closed side of the U-shaped member is located on the same plane. The two steel pipe columns of the plane are flush. In actual construction, the U-shaped member can be made of U-shaped steel or channel steel, and the three steel pipe columns and the U-shaped member are enclosed to form a rectangular t...

Embodiment 3

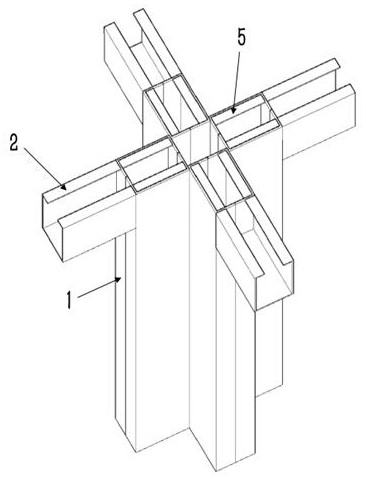

[0034] Embodiment 3: see image 3 , the basic structure is the same as that of Example 1, except that the combined special-shaped column includes four steel tube columns, which are distributed in a cross shape. Among them, two of the four steel pipe columns are located on the same plane, and a gap is formed between the two steel pipe columns located on the same plane, and the other two steel pipe columns extend into the gap and are fixedly connected with the two steel pipe columns. In actual construction, one side of the four steel pipe columns is enclosed to form a tubular space, and concrete is poured in the tubular space and the steel pipe columns to form a cross-shaped special-shaped steel pipe concrete column, which can make the concrete and steel structure better. connected into one.

[0035] A construction method for splicing special-shaped concrete-filled steel pipe column-beam-column joints, adopting splicing special-shaped steel pipe-column-beam-column joints as des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com