Engine front end water outlet structure

A water outlet structure, engine technology, applied in engine components, engine cooling, machine/engine, etc., to achieve the effect of reducing cost and weight, reducing layout difficulty, and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

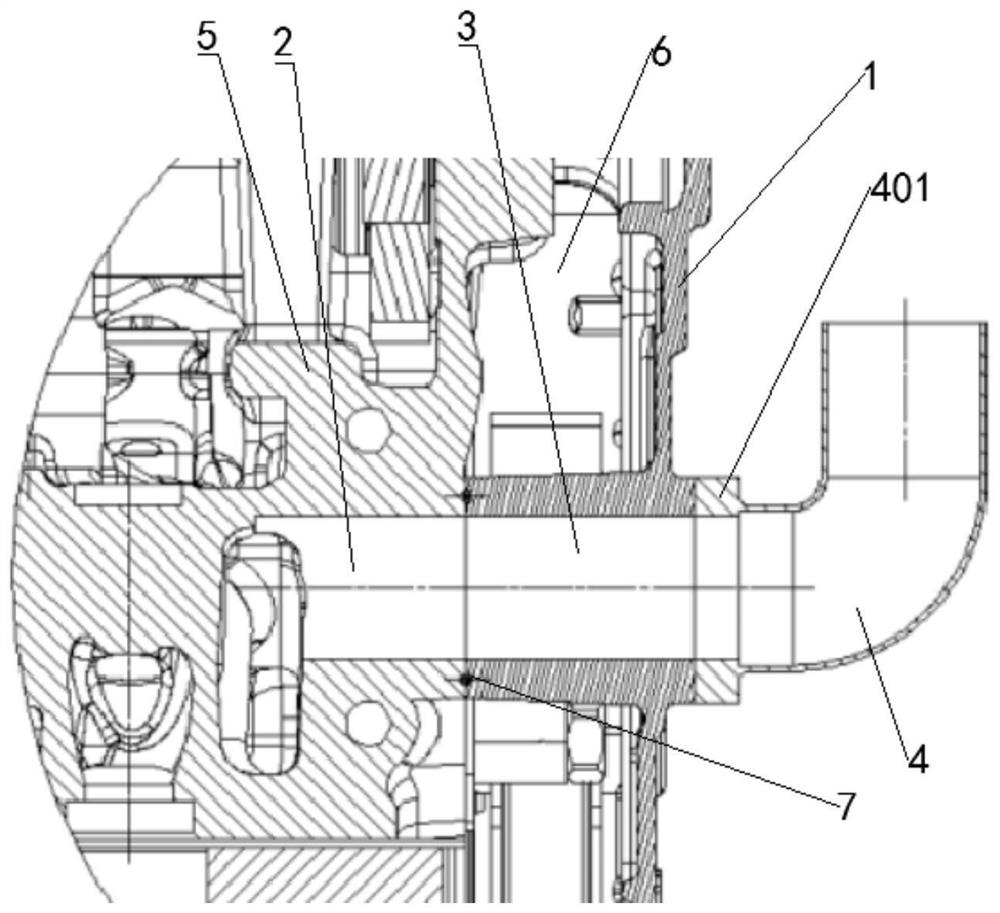

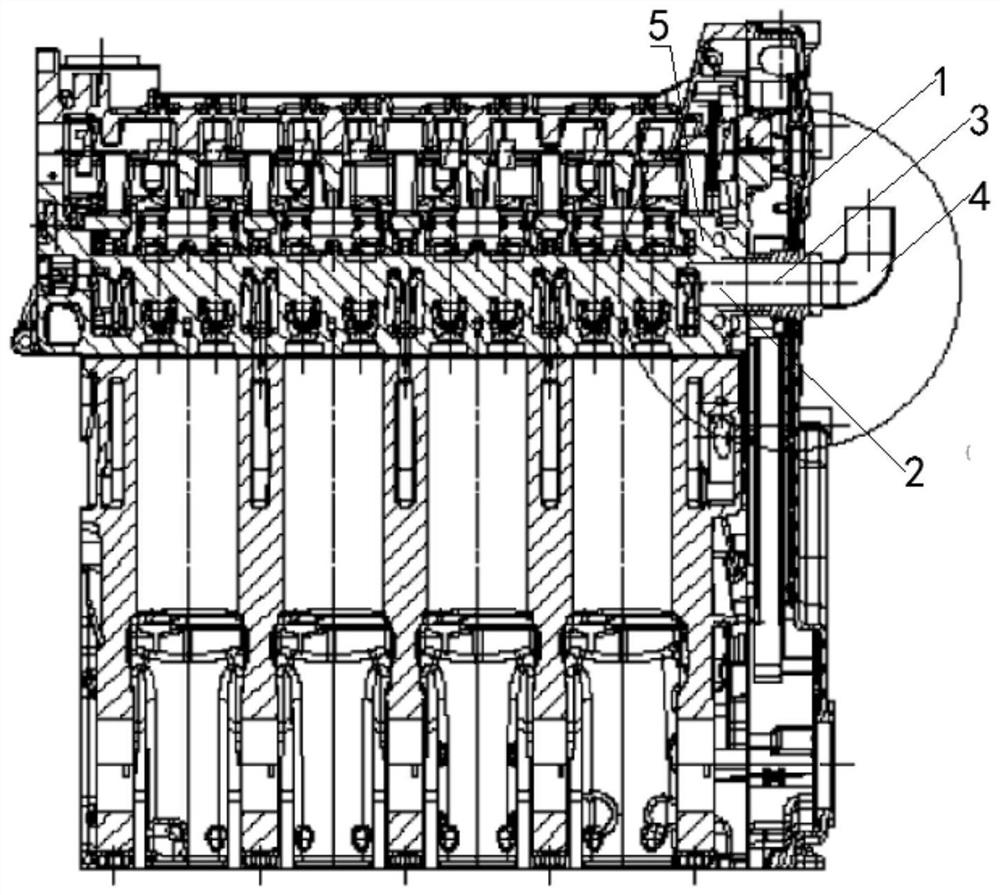

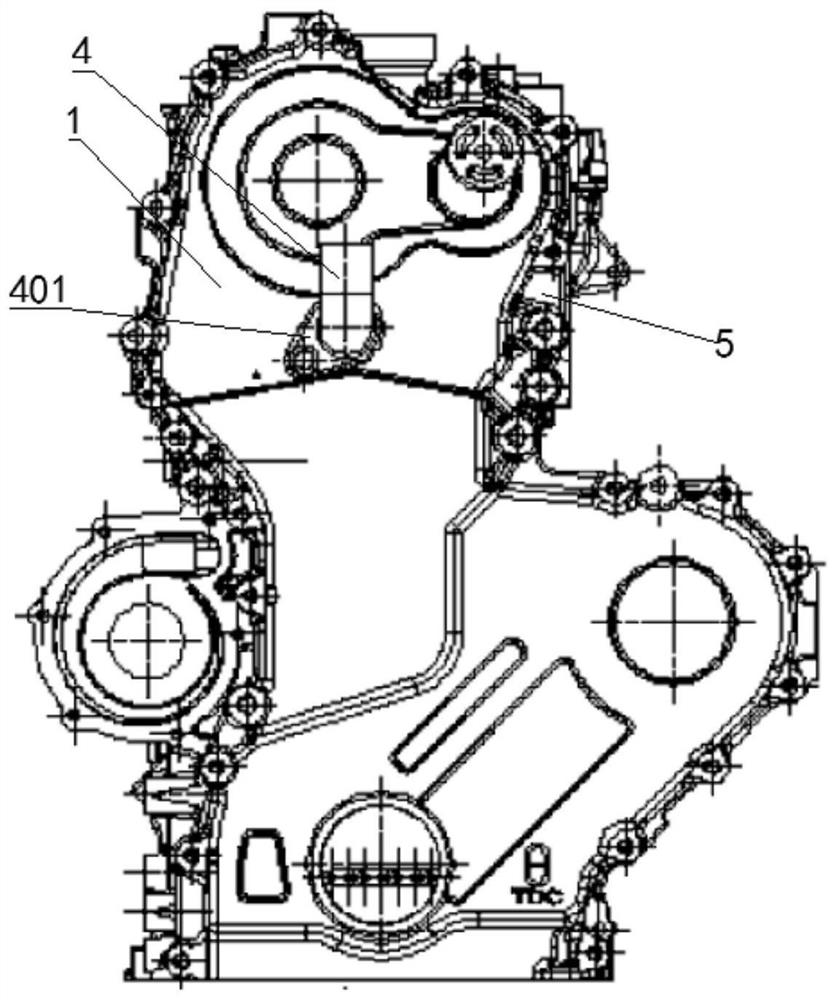

[0029] Such as Figure 1 ~ Figure 3 As shown, a water outlet structure at the front end of the engine includes a gear chamber cover 1 arranged on the front end surface of the cylinder head 5 and the outer edge of the engine gear chamber 6 for sealing fit, and a first water jacket communicating with the inside of the cylinder head 5 and the cylinder head 5 is provided. A water outlet channel 2, the gear chamber cover 1 is provided with a second water outlet channel 3 communicating with the first water outlet channel 2, and the left end surface of the second water outlet channel 3 is in sealing fit with the engine gear chamber 6 , the right side of the second water outlet channel 3 is connected to the water outlet joint 4 arranged outside the front end of the cylinder block.

[0030] The flow process of cooling liquid of the present invention is as follows:

[0031] The engine water outlet is integrated on the gear chamber cover 1 to realize the water outlet function at the fro...

Embodiment 2

[0034] In this implementation, the front end and the rear end of the engine are defined as: the end of the crankshaft where the pulley is installed is the front end of the engine, and the end where the flywheel is installed is the rear end of the engine.

[0035] Such as Figure 1 ~ Figure 3 As shown, a water outlet structure at the front end of the engine includes a gear chamber cover 1 arranged on the front end of the cylinder head 5 and the outer edge of the engine gear chamber 6 to seal and cooperate. The gear chamber cover 1 seals the front end of the cylinder head, and the gear chamber cover 1 1. It is used to seal the chains and gears in the gear chamber and prevent the lubricating oil from splashing; the first water outlet channel 2 communicating with the water jacket of the cylinder head 5 is provided inside the cylinder head 5, and the first water outlet channel 2 is used to drain the water jacket The coolant is drawn out, the gear chamber cover 1 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com