Valve plate for axial plunger motor

A technology of axial piston motor and flow plate, which is applied in the field of hydraulic pressure, can solve problems such as wear of flow plate, achieve the effects of reducing friction, prolonging service life, and various forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

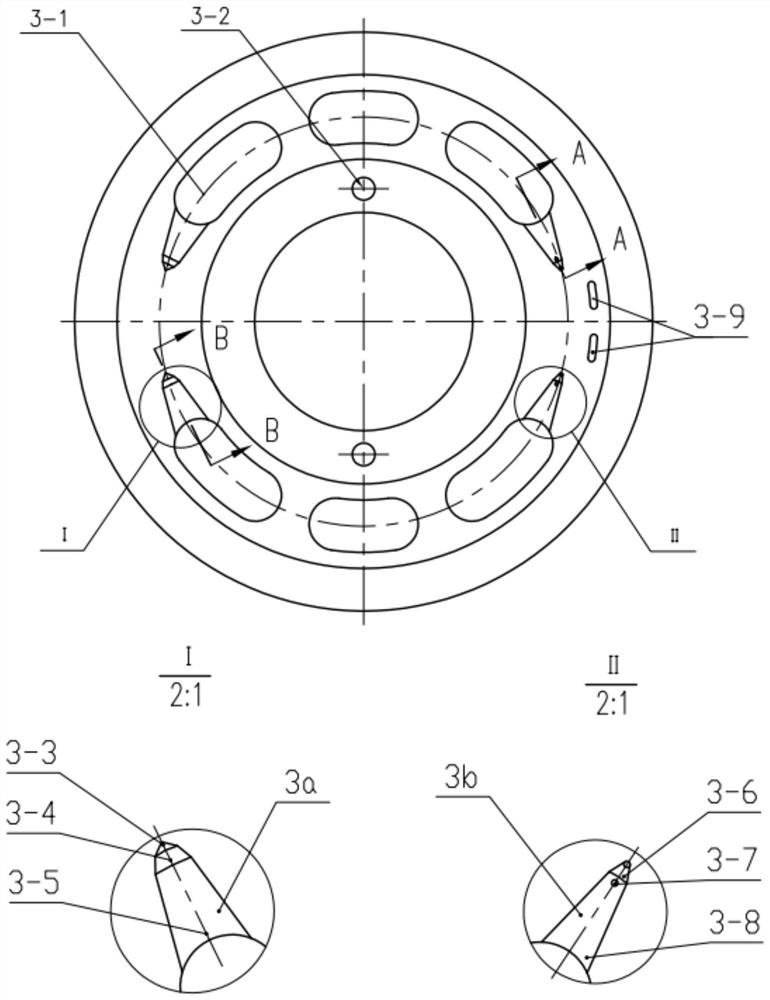

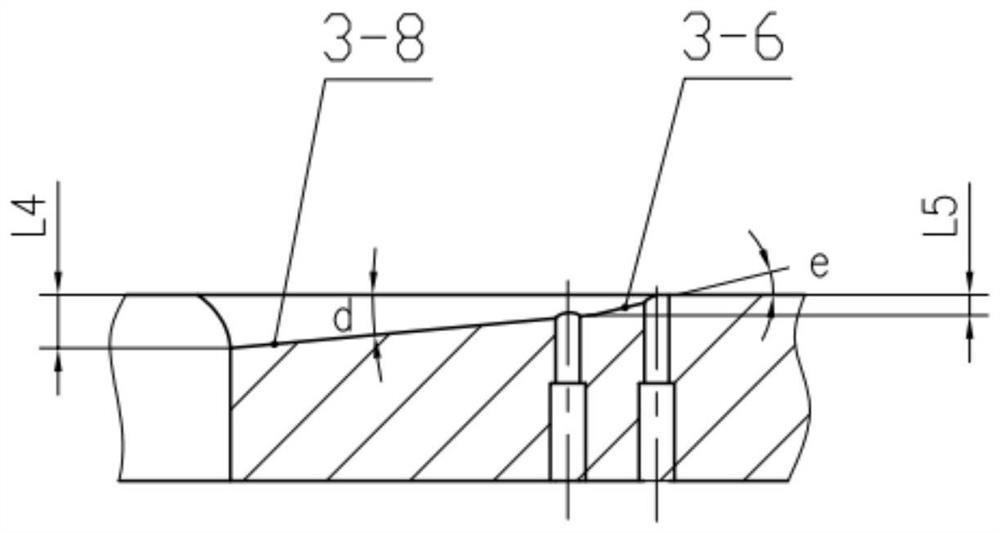

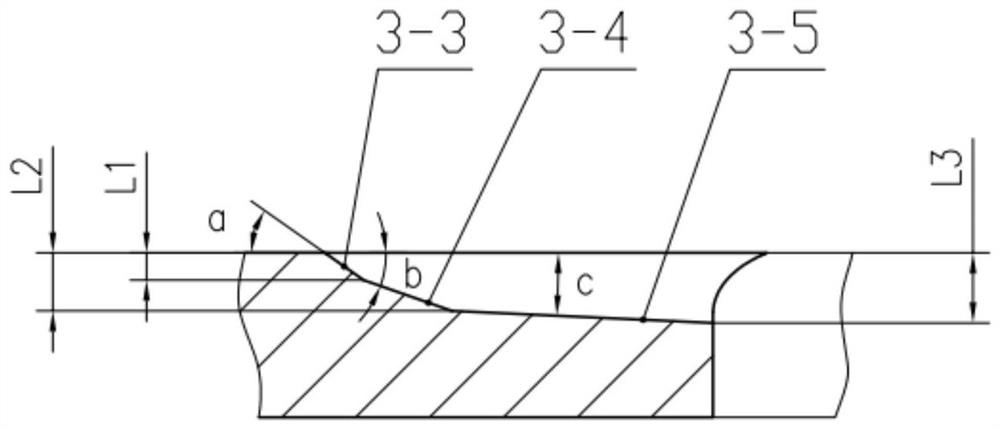

[0024] Such as Figure 1 to Figure 5 As shown, a valve plate for an axial piston motor is characterized in that it includes noise reduction and pressure relief grooves, and a plurality of noise reduction pressure relief grooves are provided in the pressure transition area on the valve plate, and the noise reduction and pressure relief grooves are composed of It consists of a U-shaped groove 3-1 and multiple V-shaped grooves. There are two symmetrical three-stage noise reduction and pressure relief grooves on one side of the flow plate, and two symmetrical two-stage noise reduction and pressure relief grooves on the other side of the flow plate. Noise relief groove, in the second-level noise reduction and pressure relief groove, throttle hole 3-7 is provided, and an oil storage tank 3-9 for improving the dynamic pressure balance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com