Fire-resistant iron sheet air pipe

A technology of iron sheets and air ducts, applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problems of waste, difficult construction, and affecting the available space of the building, so as to reduce the occupied space, increase the available space, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

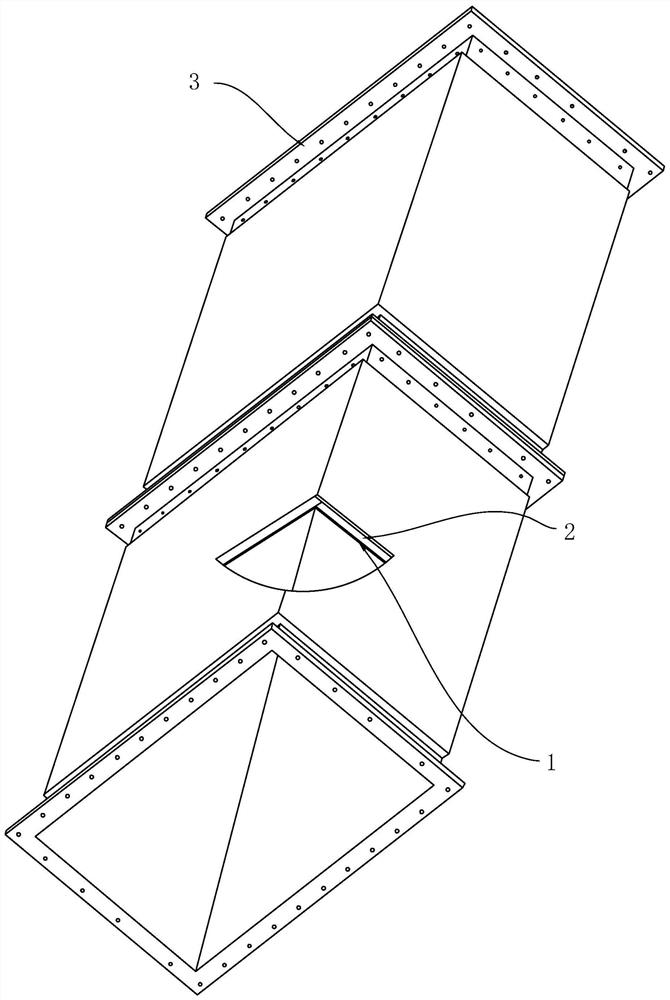

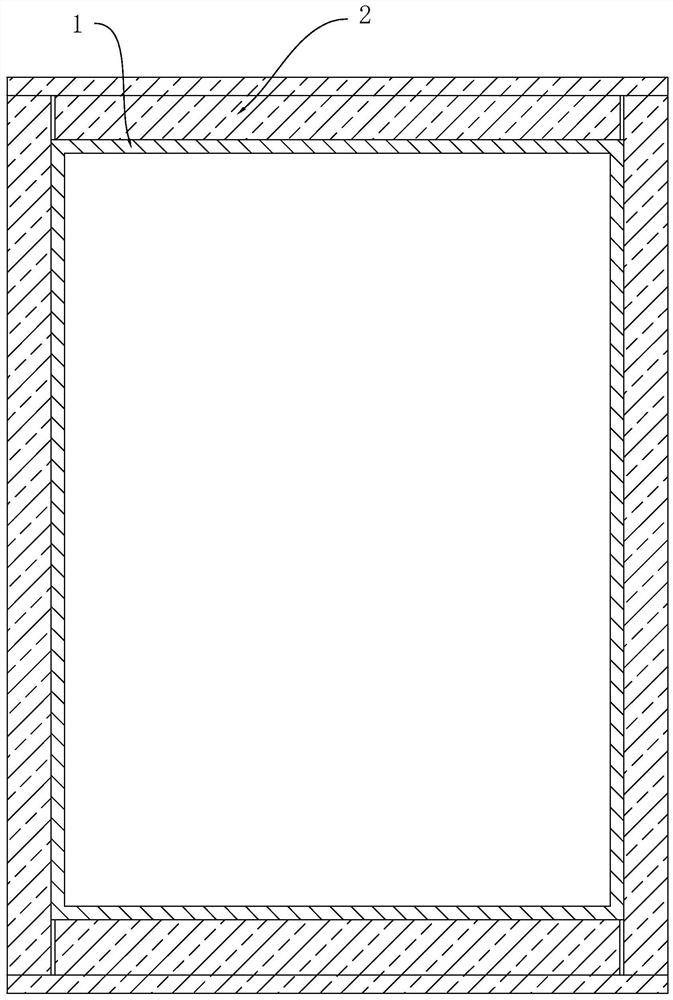

[0020] Embodiment 1: as figure 2 and image 3 As shown, the refractory iron sheet air duct includes a plurality of iron sheet air ducts 1, the cross section of the iron sheet air duct is square, and the outer wall of the iron sheet air duct is spliced with a fireproof board 2 to form a refractory iron sheet air duct. combined to form a tubular structure with a square cross section. When in use, the composite air duct is connected through the flange 3, and the flange 3 is coated with a fireproof material layer.

[0021] The fireproof board is directly compounded on the iron sheet air duct. There is no space structure directly between the fireproof board and the iron sheet air duct, and the flange used to connect the adjacent air duct is exposed. The purpose of fire resistance is achieved by coating the fireproof material with the same fire resistance time, that is, It meets the requirements of fire resistance, and can greatly reduce the space occupied by the air duct, incr...

Embodiment 2

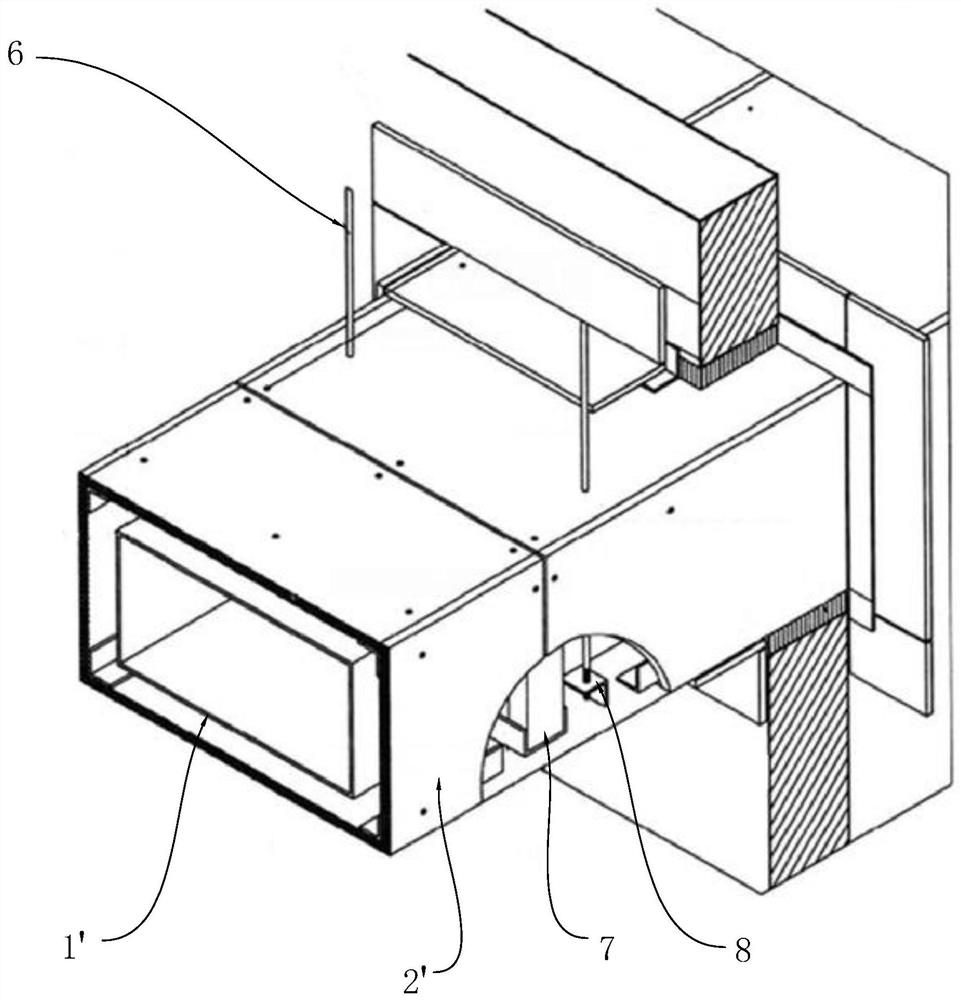

[0028] Embodiment 2: as Figure 7 As shown, the end of the fireproof board is flush with the end of the iron air duct, and the flange is fixed on the fireproof board. The rest of the structure on the refractory iron sheet air duct is the same as that in Example 1. During construction, before installing the flange, first cover the iron sheet air duct section by section with a fireproof board, and then wrap the adjacent composite air ducts that have been coated. The pipe forms a connection with the flange.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com