Method and system for automatically testing resistance value and marking automobile temperature sensor

A temperature sensor and automatic testing technology, applied in thermometer testing/calibration, thermometer, measuring resistance/reactance/impedance, etc., can solve the problems of constant temperature time of the product to be tested, cumbersome testing process, constant water temperature standard cannot be given, etc. , to achieve the effects of improving test efficiency and test reliability, improving resistance test accuracy, and facilitating traceability and research analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

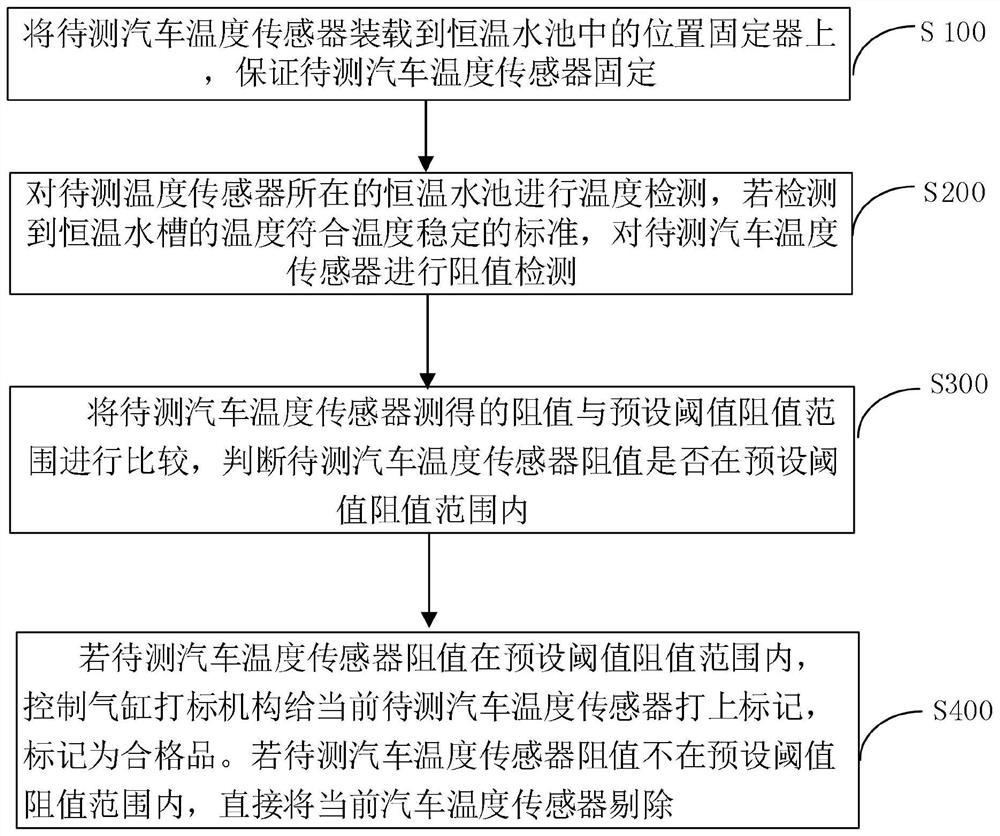

[0032] A method for automatically testing and marking the resistance value of an automobile temperature sensor, characterized in that it includes:

[0033] S100. Load the temperature sensor of the vehicle to be tested on the position fixer in the constant temperature water pool to ensure that the temperature sensor of the vehicle to be tested is fixed.

[0034] In some preferred embodiments, the raw material of the position fixer is epoxy resin, and 7 car temperature sensors to be tested are loaded at a time, and the two metal pins of the car temperature sensor to be tested transmit the signal through a flexible probe. The surface is gold-plated, the contact resistance between the test probe and the product pin of the temperature sensor is less than 10mΩ, and the tail of the test probe is welded with a copper core wire to lead the signal to the terminal of the relay of the control unit. The test software controls the relay "Action" / The "OFF" state adjusts which resistance val...

Embodiment 2

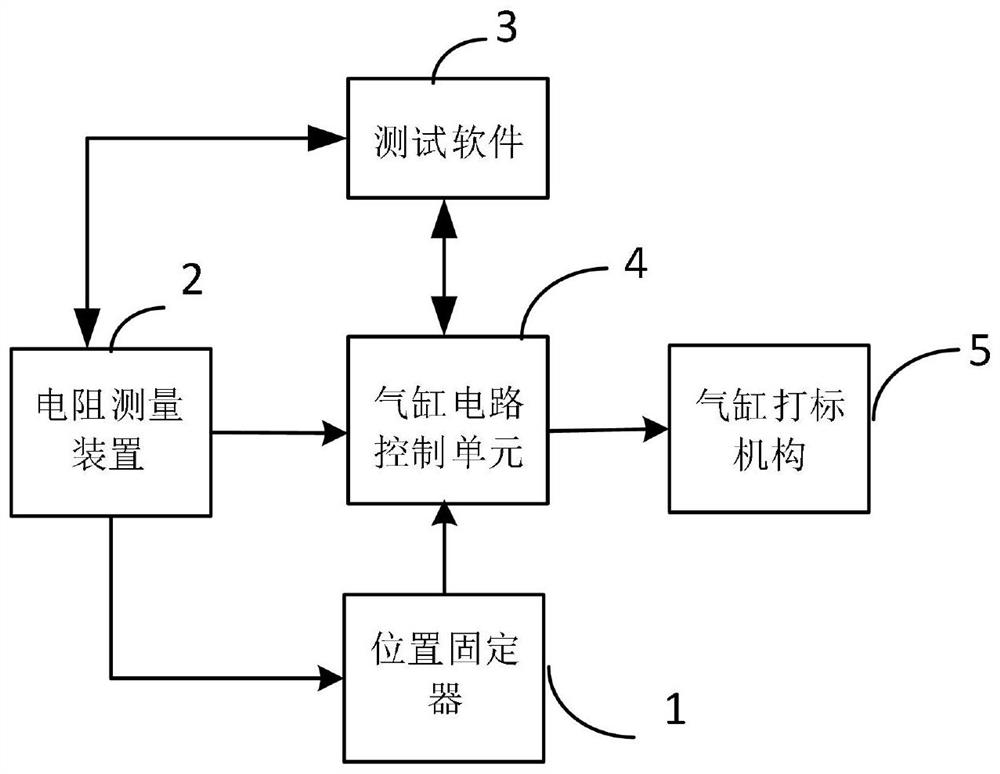

[0047] This embodiment discloses a system for automatically testing and marking the resistance value of an automobile temperature sensor, which is characterized in that it includes: a position fixer, a multimeter, testing software, a cylinder circuit control unit, and a cylinder marking machine; wherein:

[0048] The position fixer is used to fix the temperature sensor of the car to be tested in the constant temperature water pool. The raw material of the position fixer is epoxy resin, and 7 car temperature sensors to be tested are loaded at a time. The two metal pins of the car temperature sensor to be tested transmit the signal through the elastic probe. The surface of the probe is gold-plated. The test probe and The contact impedance of the product pins is less than 10mΩ, and the tail of the test probe is welded with a copper core wire to lead the signal to the relay terminal of the control unit. The resistance value of one. This connection method ensures that the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com