Electric operating mechanism of chassis truck

A technology of electric operating mechanism and chassis car, which is applied in the direction of electrical components, switchgear, pull-out switchgear, etc. It can solve the problems of potential safety hazards, inconvenient installation, broken and worn limit joints, etc., and achieves easy maintenance and maintenance. Eliminate potential safety hazards and achieve precise rotation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

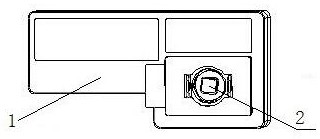

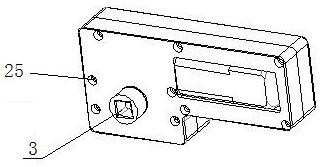

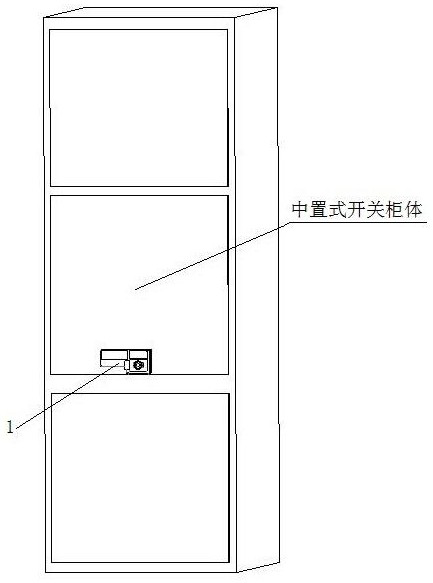

[0030] Such as Figure 1 to Figure 13 The chassis car electric operating mechanism shown is composed of a casing 1 arranged on the outer wall of the middle part of the switch cabinet and a driving assembly arranged in the casing 1; the driving assembly includes a motor mounting plate arranged in one end of the casing 1 5. The rear mounting plate 6, and the motor 4 arranged in the other end of the casing 1, and the outlet gear 7 arranged on the upper side of the motor mounting plate 5 and connected to the motor 4, and the two ends are respectively connected to the motor mounting plate 5, the rear The worm 9 connected to the upper mounting plate 6, the transmission spur gear 8 arranged at one end of the worm 9 and used in conjunction with the outlet gear 7, and the worm gear 8 arranged between the motor mounting plate 5 and the rear mounting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com