Production system of chicken essence

A production system and technology for chicken essence, applied in the field of chicken essence production system, can solve the problems of cumbersome steps, high motor energy consumption, increase cost, etc., and achieve the effects of reducing operation steps, reducing burden, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

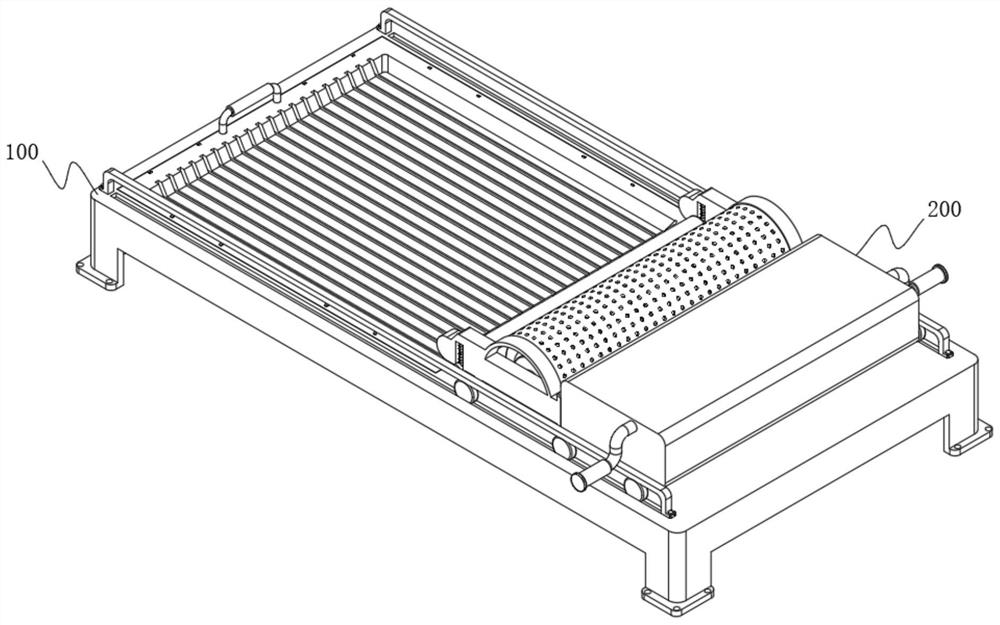

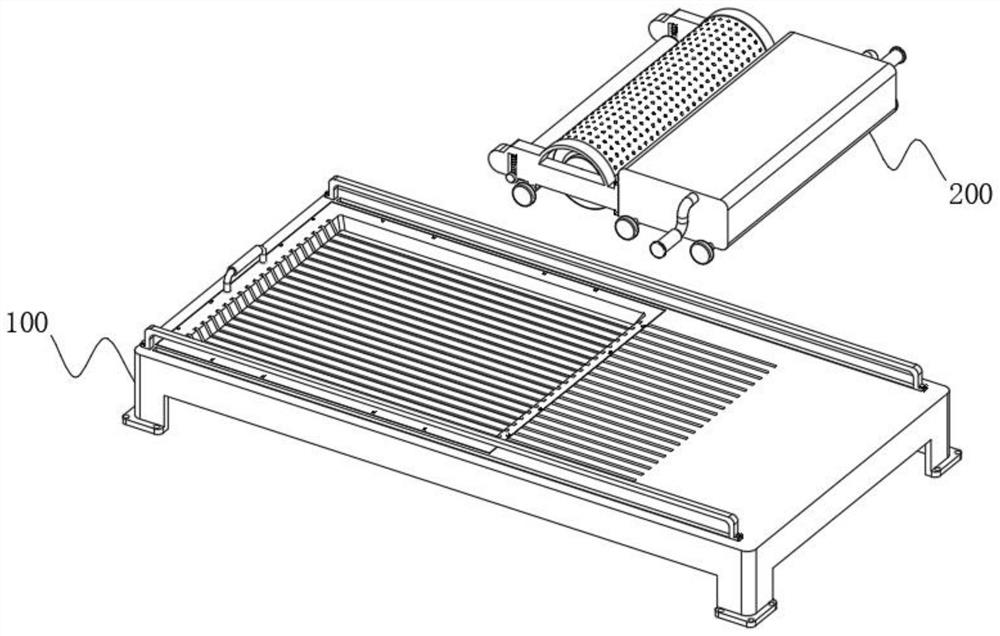

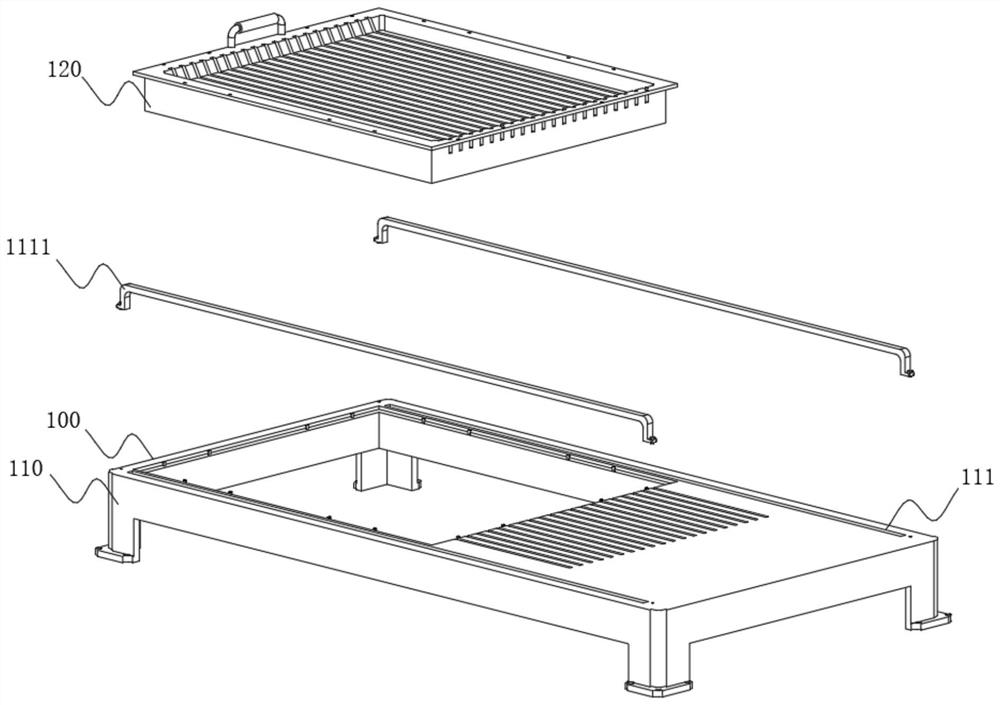

[0063] The present invention provides a production system for chicken essence, please refer to Figure 1-Figure 12 , including a supporting device 100 and a cutting device 200 arranged on the top of the supporting device 100, the supporting device 100 includes a base 110, the top of the front side of the base 110 is provided with a plugging slot 113, and a charging box 120 is arranged in the plugging slot 113, The top of the material box 120 is provided with a charging groove 121. In order to ensure that the longitudinal cutting wheel 222 has enough room to rotate, the tops of the base 110 and the charging groove 121 are respectively provided with a plurality of first reserved grooves 112 and second reserved grooves 1211. And the first reserved groove 112 is docked with the second reserved groove 1211, so that the longitudinal cutting wheel 222 smoothly enters the second reserved groove 1211 from the first reserved groove 112, and the top of the base 110 is located on the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com