Inclinable food processing stirrer

A technology for food processing and mixers, which is applied to mixer accessories, mixers with rotating mixing devices, mixers, etc., can solve the problems of the uniformity of mixing, the great influence on the taste of biscuits, the formation of a hard block, and the agglomeration easily affected by moisture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

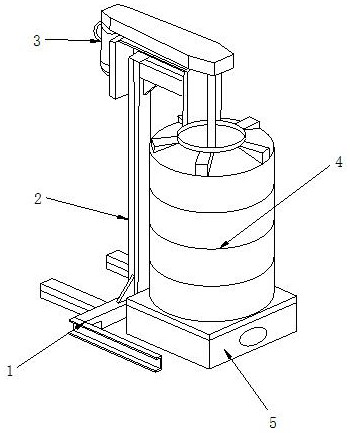

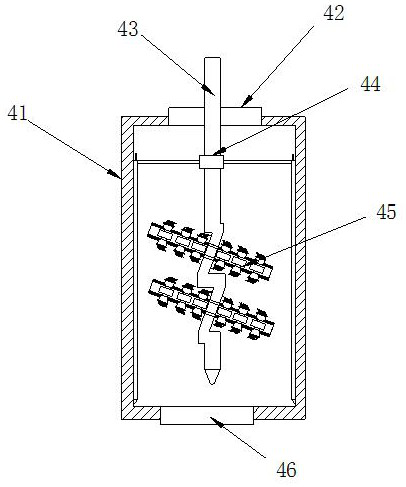

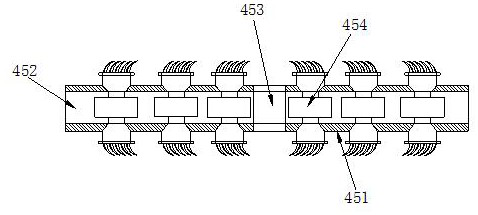

[0024] see Figure 1-Figure 5 , the specific embodiments of the present invention are as follows: a tiltable food processing mixer, its structure includes a base 1, a support 2, a mixer 3, a mixing bucket 4, an inclined discharge port 5, and the top surface of the base 1 is welded to the bottom surface of the support 2 connected, the bottom surface of the mixer 3 is fixedly installed on the top surface of the bracket 2, the top of the mixing bucket 4 is fixedly connected to one side of the mixer 3, and the top of the inclined outlet 5 is connected to the bottom of the mixing bucket 4; the mixing bucket 4 includes an outer wall 41, a material inlet 42, a stirring shaft 43, a scraper 44, an adhesive breaker 45, and a discharge port 46. The top of the outer wall 41 and the outer ring of the material inlet 42 are integrally formed, and the stirring shaft The outer ring of 43 is fixedly connected with the inner ring of the scraper knife 44, the interior of the adhesive breaker 45 i...

Embodiment 2

[0030] see Figure 6-Figure 7 The specific embodiment of the present invention is as follows: the scraper 44 includes a connection block 441, a drive handle 442, a fixed shaft 443, and a scraper 444, the outer ring of the connection block 441 is welded to one side of the drive handle 442, and the fixed shaft The top of 443 is welded to the other side of the drive handle 442, and the outer ring of the fixed shaft 443 is connected to the center of the scraper 444 by interference. The scraper 444 is made of 304 stainless steel, which is conducive to increasing the hygiene level during use and avoiding poisoning.

[0031] Wherein, the scraper 444 includes an access block B1, a sliding layer B2, a connecting ring B3, and a shovel head B4, the outer ring of the access block B1 is fixedly connected with the inner ring of the sliding layer B2, and the outer ring of the access block B1 passes through The sliding layer B2 is movably engaged with the inner ring of the connection ring B3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com