Heat input adjustable consumable electrode arc additive manufacturing method and device

A melting electrode and heat input technology, applied in the field of additive manufacturing, can solve the problems of affecting the welding quality, not being able to combine well, reducing the deposition efficiency, etc., to solve the heat accumulation and heat shortage, avoid heat accumulation and heat shortage, The effect of improving the forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take the example of adding a high-strength steel straight wall body with length 110mm×width 8mm×height 80mm on a steel plate with length 180mm×width 120mm×height 10mm.

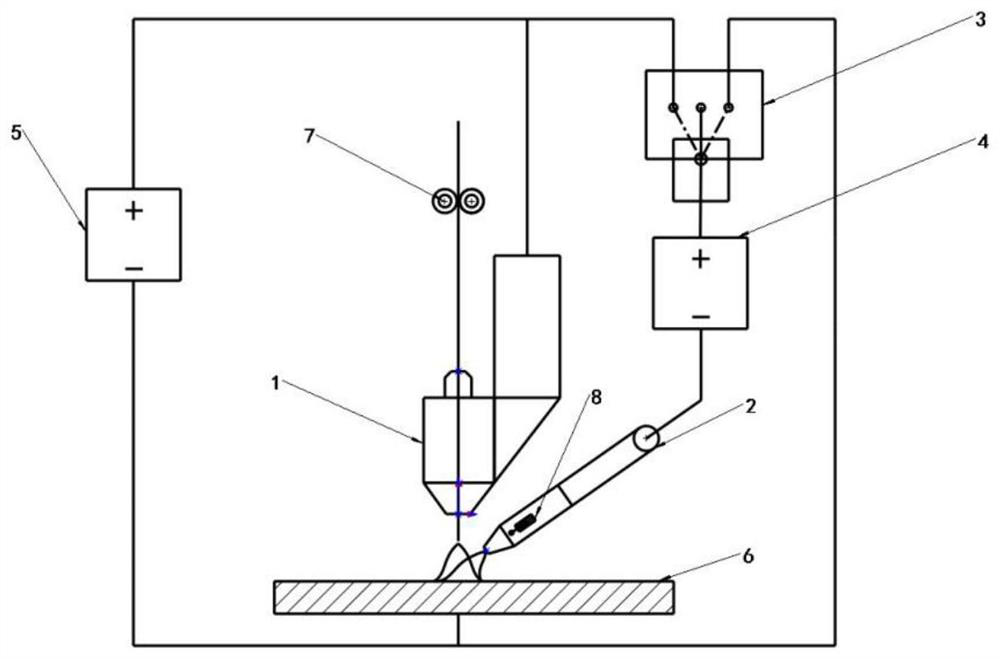

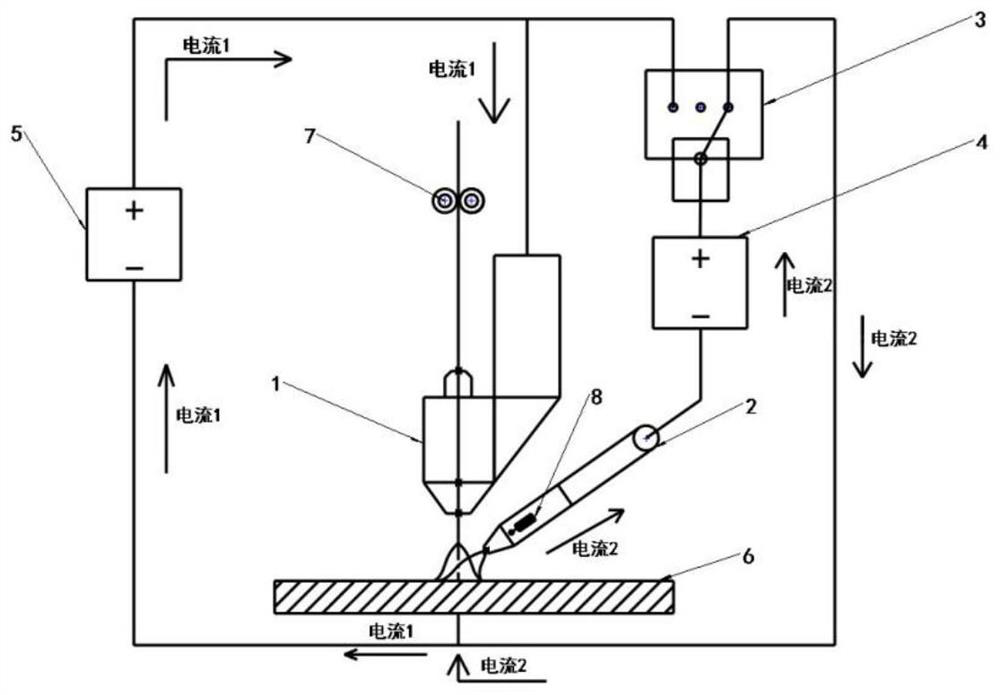

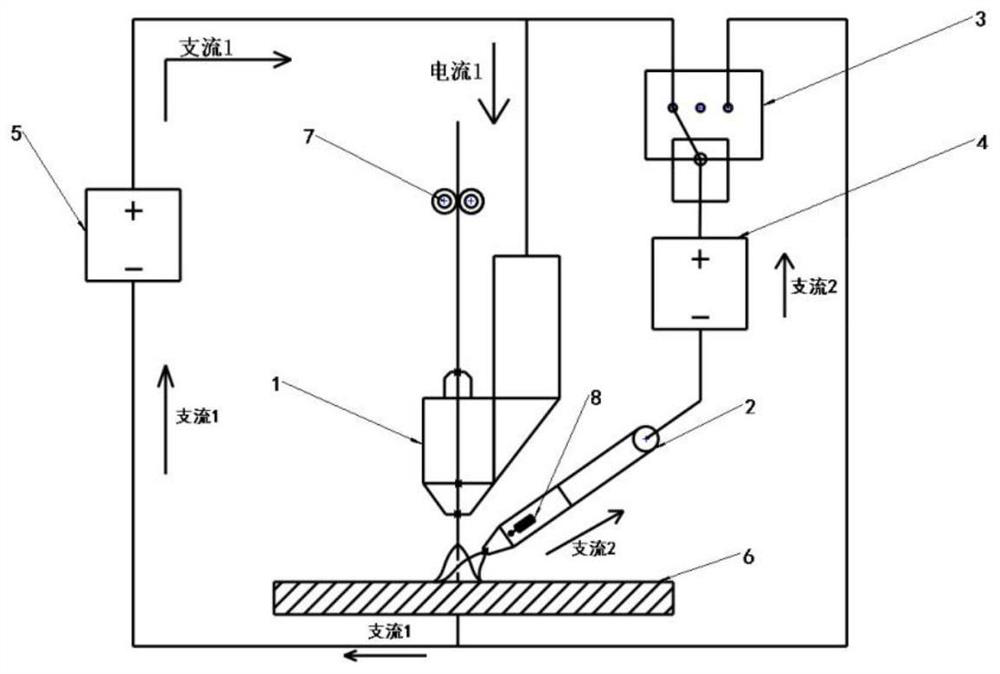

[0036] Such as figure 1Shown is a schematic structural view of the device. The figure includes melting electrode welding torch 1 , melting electrode welding power supply 5 , melting electrode wire feeder 7 , TIG welding torch 2 , TIG welding power supply 4 , circuit intelligent switcher 3 and temperature sensor 8 . Among them, the melting electrode welding torch 1, the melting electrode welding power supply 5 and the workpiece are connected in series to form a melting electrode circuit; the melting electrode welding power supply, TIG welding power supply, TIG welding torch, and workpiece are connected in series to form a non-melting electrode bypass arc circuit; TIG welding torch 2, TIG welding power supply 4 and the workpiece are connected in series to form a non-melting electrode arc circuit. The th...

Embodiment 2

[0044] Take the example of adding an 80mm long x 80mm wide x 80mm high nitrogen steel block on a steel plate with a length of 150mm x width of 150mm x height of 10mm.

[0045] This embodiment 2 adopts such as figure 1 The device structure shown. The figure includes melting electrode welding torch 1 , melting electrode welding power supply 5 , melting electrode wire feeder 7 , TIG welding torch 2 , TIG welding power supply 4 , circuit intelligent switcher 3 and temperature sensor 8 . Among them, the melting electrode welding torch 1, the melting electrode welding power supply 5 and the workpiece are connected in series to form a melting electrode circuit; the melting electrode welding power supply, TIG welding power supply, TIG welding torch, and workpiece are connected in series to form a non-melting electrode arc bypass; TIG welding torch 2 and TIG welding power supply 4 And the workpiece is connected in series to form a non-melting electrode arc circuit. The three circuits...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com