Automatic feeding equipment for screws and flat gaskets of motor fixing pieces of automobile lifting window

A technology of automatic material feeding and window motor, applied in the direction of coating, etc., can solve the problems of low production efficiency, affecting output and quality, and high labor intensity, so as to improve production efficiency, reduce enterprise waste, and reduce employee load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

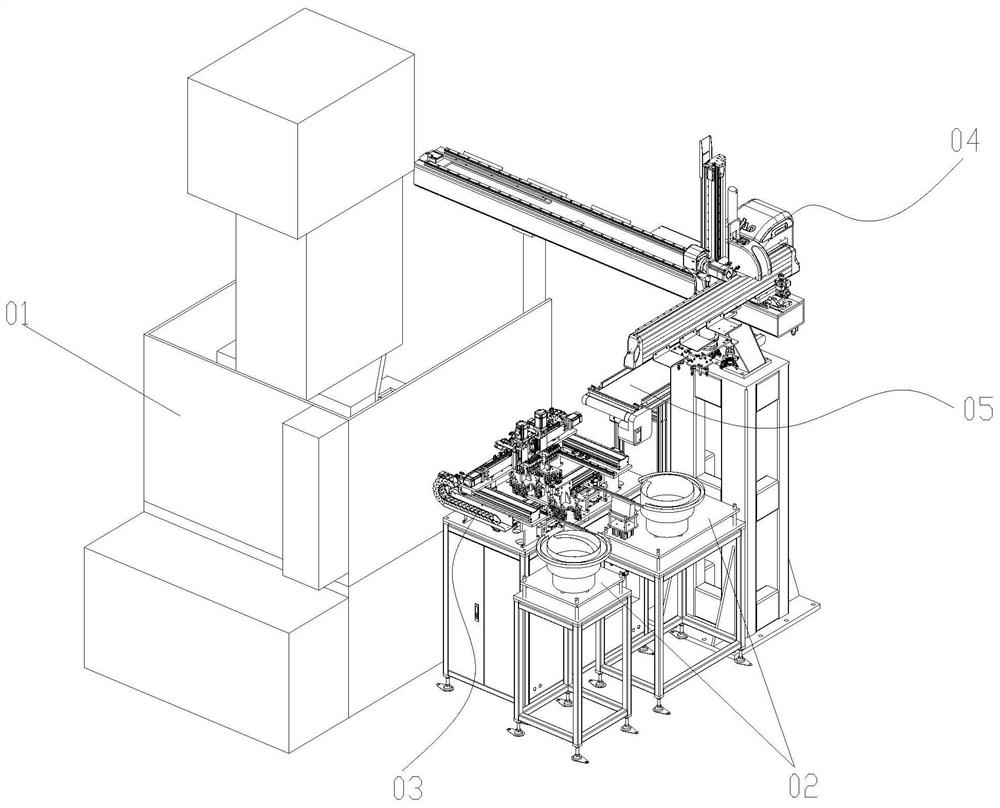

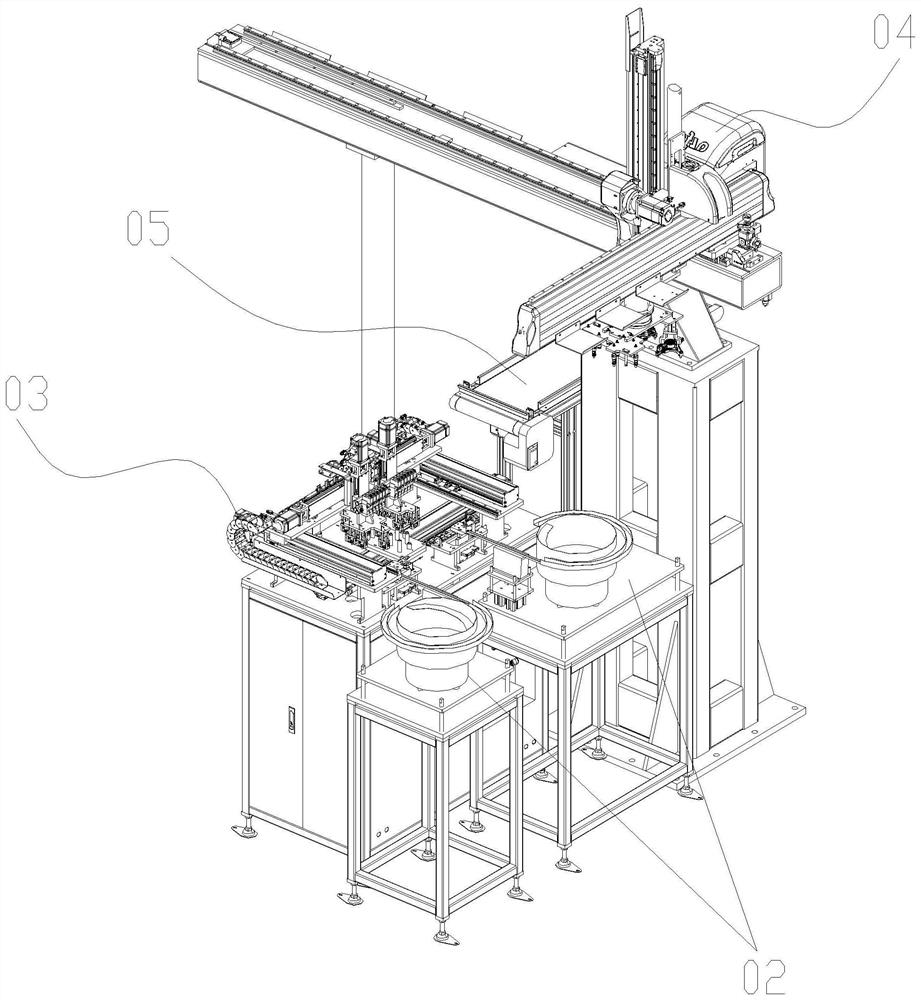

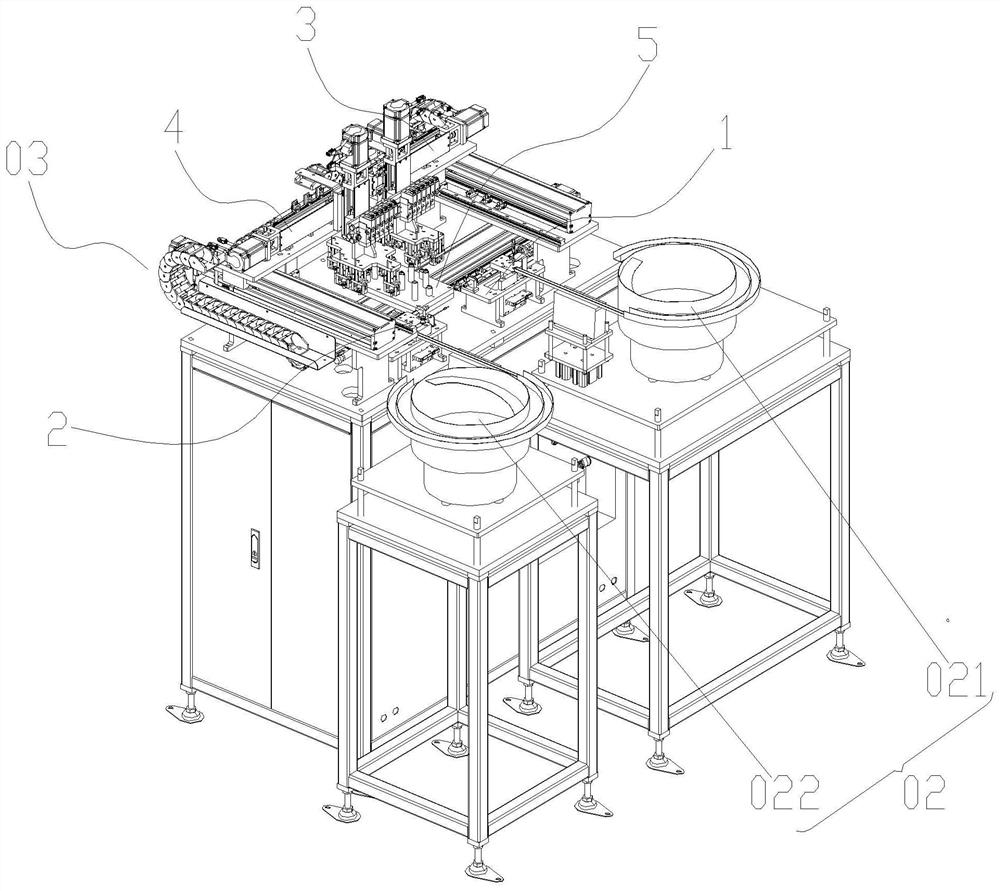

[0057] As shown in Figure 1, an automatic feeding device for the screws and flat pads of the automotive window motor fixing parts is used in conjunction with the injection molding machine 01, and is installed on the outside of the injection molding machine 01 to realize inserts (screws, flat pads) ) is automatically embedded in the mold, such as figure 2 , image 3 As shown, its structure includes a vibration feeding mechanism 02 for sequentially feeding screws and flat pads, an arrangement feeding mechanism 03 for respectively realizing the arrangement and placement of screws and flat pads, and a feeding mechanism 03 for realizing the transfer of screws and flat pads to The embedded pick-up mechanism 04 in the injection molding machine 01, and the finished product conveying mechanism 05 for transporting the finished product.

[0058] like image 3 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com