Forming process of heat-conducting gasket containing directionally sorted carbon fibers

A heat-conducting gasket and molding process technology, which is applied in the field of carbon-fiber directional sorting heat-conducting gasket forming technology, can solve the problems of low orientation and inability to increase thermal conductivity, and achieve the effect of increasing quality and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The application will be described in further detail below in conjunction with the accompanying drawings.

[0043] In this application, the vinyl silicone oil 1000 mPa·s is selected from CX-352 (1000) of Guangzhou Chenxi New Material Technology Co., Ltd., and the vinyl silicone oil of 10000 mPa·s is selected from Guangzhou Chenxi New Material Technology Co., Ltd. CX-352 ( 10000), the retarder is PH from Zijun Chemical (Zhongshan) Co., Ltd., the MQ resin is AM-8071 from Guangzhou Xinhou Chemical Technology Co., Ltd., and the platinum catalyst is PT2000 from Zijun Chemical (Zhongshan) Co., Ltd.

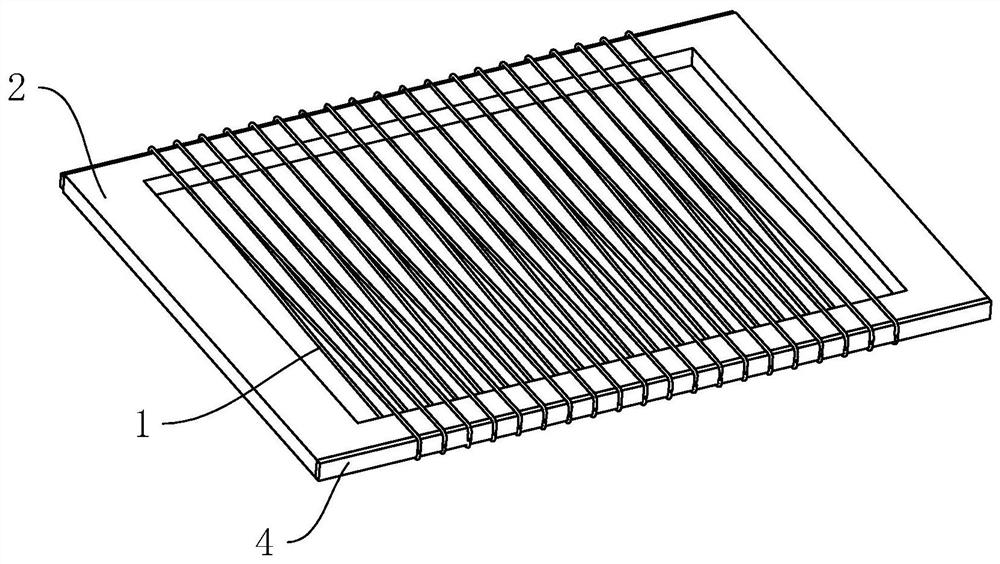

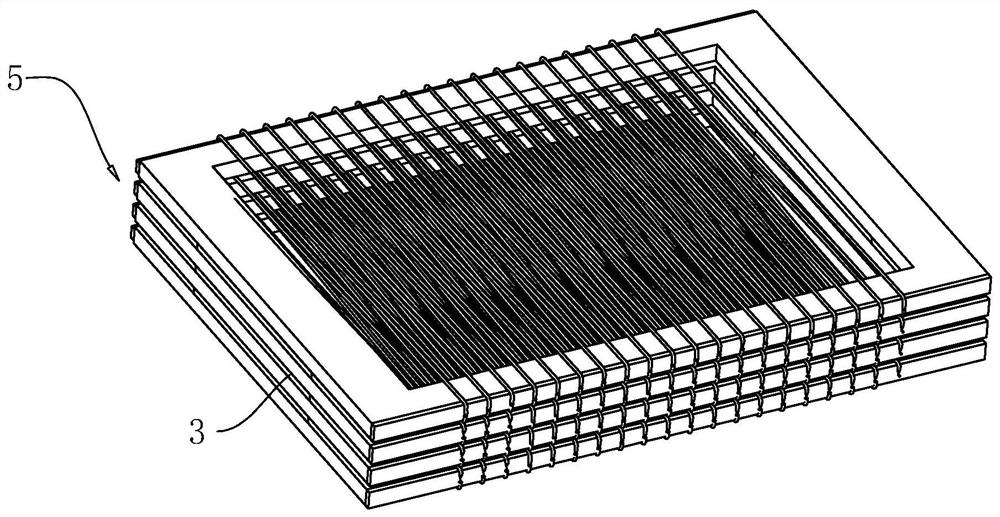

[0044] The process for forming a thermally conductive gasket containing carbon fibers in an orientation arrangement disclosed in the present application enables the carbon fiber filaments 1 of the produced gasket to face the same direction, thereby increasing the thermal conductivity of the produced gasket.

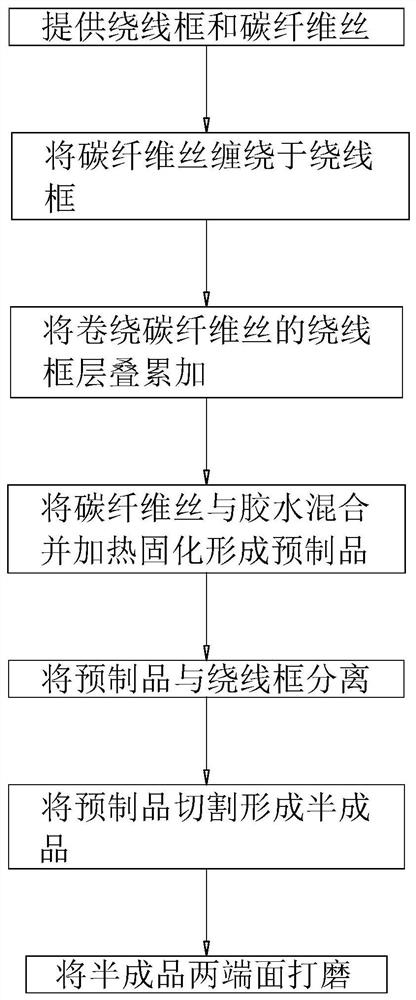

[0045] Such as figure 1 shown, including the following steps:

[0046]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com