Automatic cage nail welding device

An automatic welding and cage nail technology, which is used in glass remolding, glass manufacturing equipment, glass molding, etc., can solve the problems of poor welding quality and difficult to guarantee, and achieve good product consistency, quality assurance, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

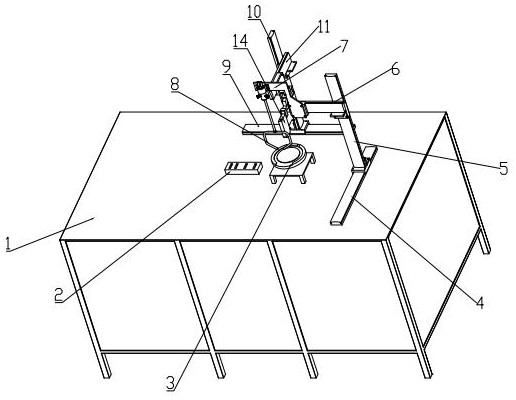

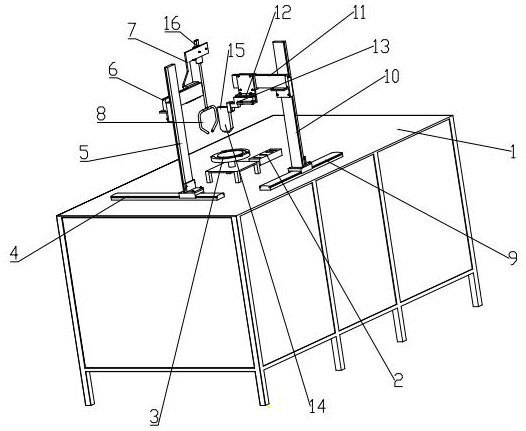

Image

Examples

Embodiment

[0019] Embodiment: When in use, the cage piece is placed above the cage piece mold 3, and the cage nail suction head 14 can be connected to an external vacuum pump through the vacuum pump connection hole 15 above to provide suction for the cage nail suction head 14, and then adjust the second water skiing platform , the second vertical slide table 10 and the second adjustment slide table 11 make the cage nail suction head 14 absorb the cage nails in the cage nail seat 2, and drive it to the to-be-welded point of the cage sheet, and then adjust the first level The slide table 4, the first vertical slide table 5 and the first adjustment slide table 6 make the flame blowtorch 8 below the support 7 move to the working range, and input hydrogen and oxygen through the external pipeline of the hydrogen and oxygen input joint 17 to make the flame blowtorch 8 Start the welding work. In particular, the above slides are all linear electric slides, which are easy to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com