Assembly type conical special-shaped steel pipe column foot with restorable function and assembly method

A special-shaped steel pipe, a technology for restoring functions, applied in the directions of columns, pillars, piers, etc., can solve problems such as residual deformation, and achieve the effects of consistent seismic performance, reduced residual deformation, and high degree of assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

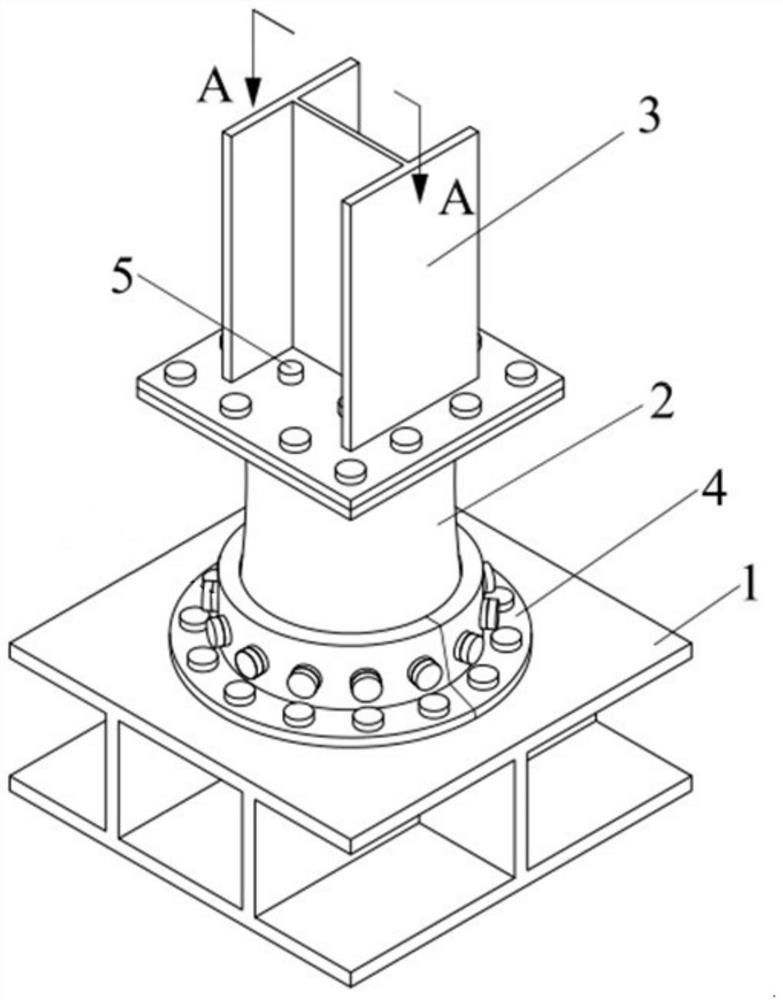

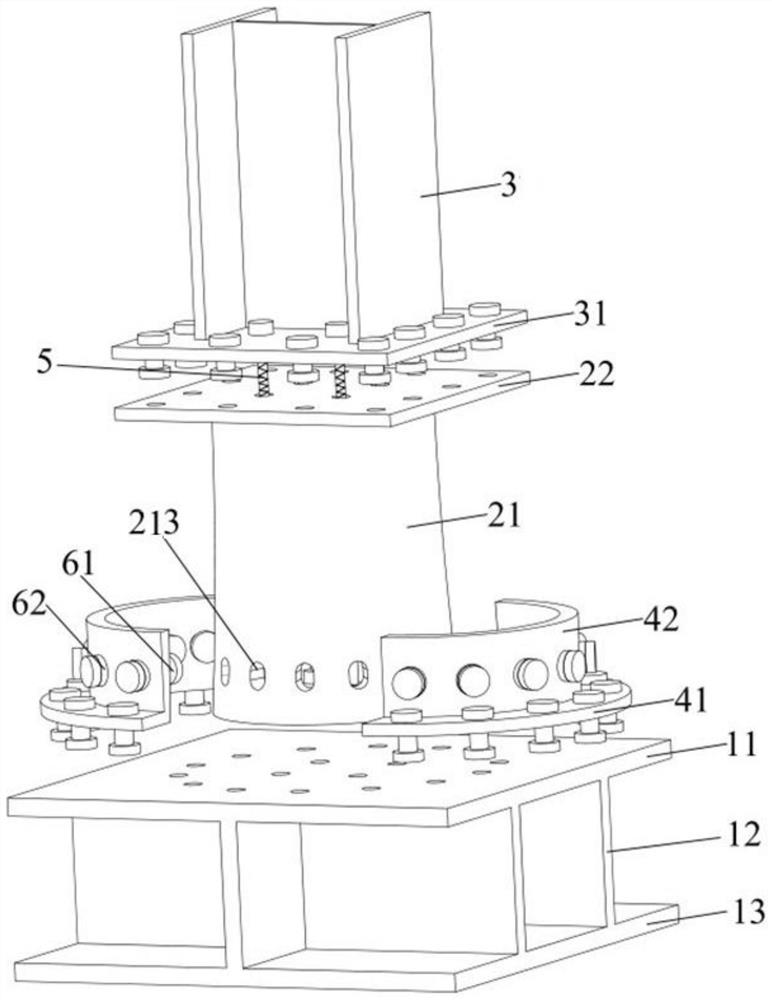

[0045] see figure 1 , this embodiment discloses an assembled conical special-shaped steel pipe column foot with a recoverable function, including a box-shaped foundation 1, a conical special-shaped steel pipe short column 2, an I-shaped steel column 3, a semicircular arc angle steel 4, and a prestressed cable 5 And shaped mild steel ring spring.

[0046] see Figure 4 , the short column 2 of the conical special-shaped steel pipe includes a conical special-shaped steel pipe 21 and an upper end plate 22, the conical special-shaped steel pipe 21 is vertically arranged, the horizontal upper end plate 22 is welded on the upper end of the conical special-shaped steel pipe 21, and the weld is a double-sided fillet weld.

[0047] see Figure 5 , the conical special-shaped steel pipe 21 is a conical pipe fitting, and the outer wall and inner wall of the conical special-shaped steel pipe 21 are recorded as a conical pipe wall 211 and a cylindrical curved pipe wall 212 respectively. A...

Embodiment 2

[0059] This embodiment discloses a method for assembling a assembled conical special-shaped steel pipe column foot with a recoverable function based on Embodiment 1, including the following steps:

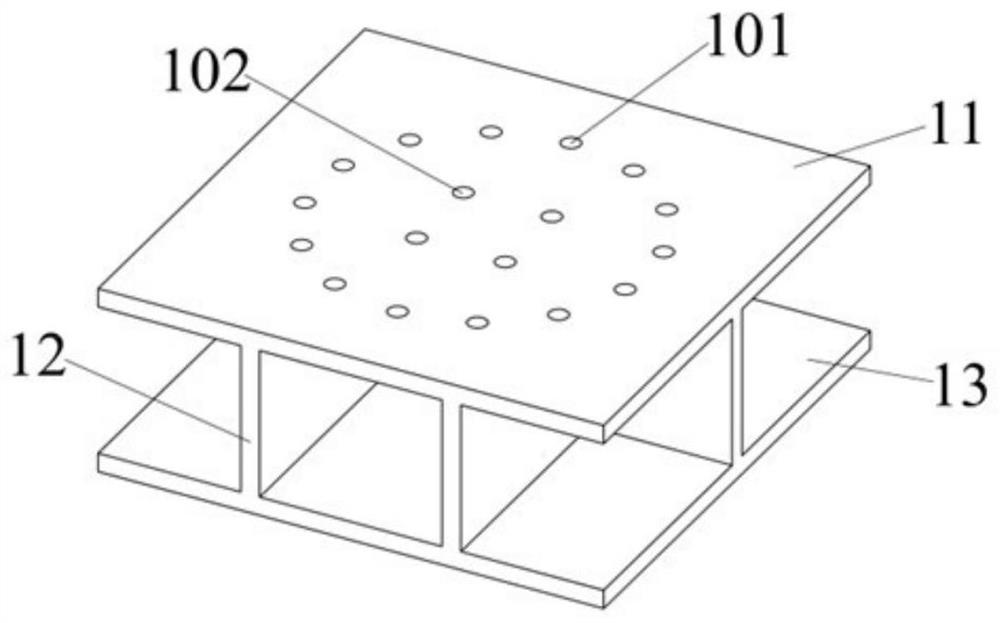

[0060] 1) The box-shaped foundation 1, the conical special-shaped steel pipe short column 2, the I-shaped steel column 3, the semicircular arc angle steel 4, the prestressed cable 5 and the special-shaped mild steel ring spring are produced in the factory. Among them, see image 3 The box-shaped foundation 1 includes an upper flange 11, a web 12 and a lower flange 13, the upper flange 11 is provided with several bolt holes I101 and prestressed cable anchor holes I102, and the conical special-shaped steel pipe 21 is provided with several oblong bolt holes 213, the upper end plate 22 is provided with several bolt holes II202 and several prestressed cable penetration holes 203, the plane plate 41 is provided with several bolt holes III401, the conical special-shaped plate surface 42 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com