Thin-wall section steel floor slab layer

A thin-walled section steel and floor slab technology, which is applied to floors, building components, buildings, etc., can solve the problems of complex process and difficult construction, and achieve the effect of speeding up the construction progress and reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

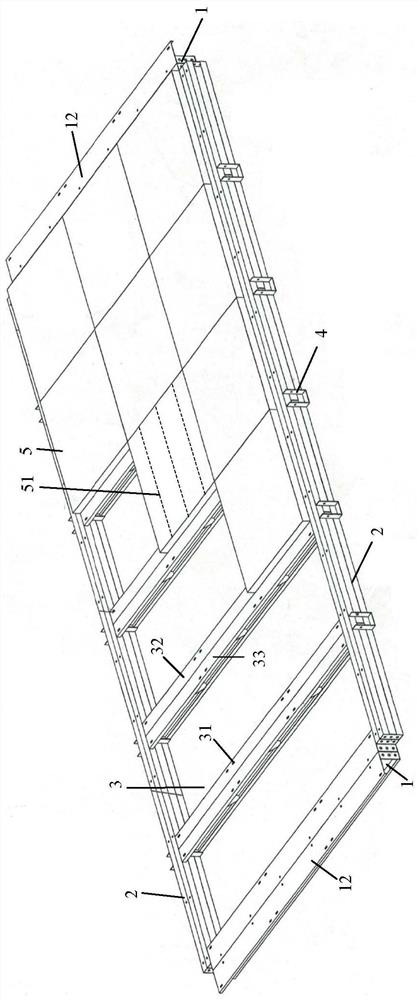

[0027] figure 1 A basic thin-walled steel floor slab layer according to the present invention is shown, and a plurality of basic thin-walled shaped steel floor slab layers can be spliced together to form a floor slab layer as required.

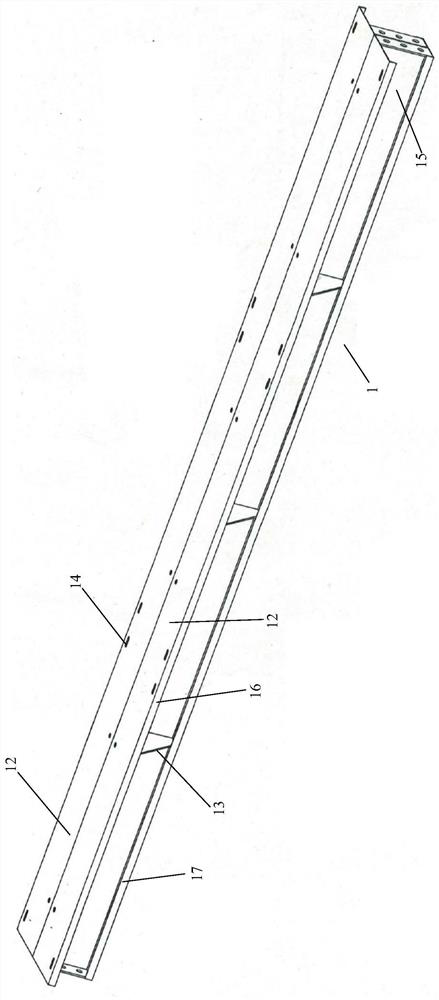

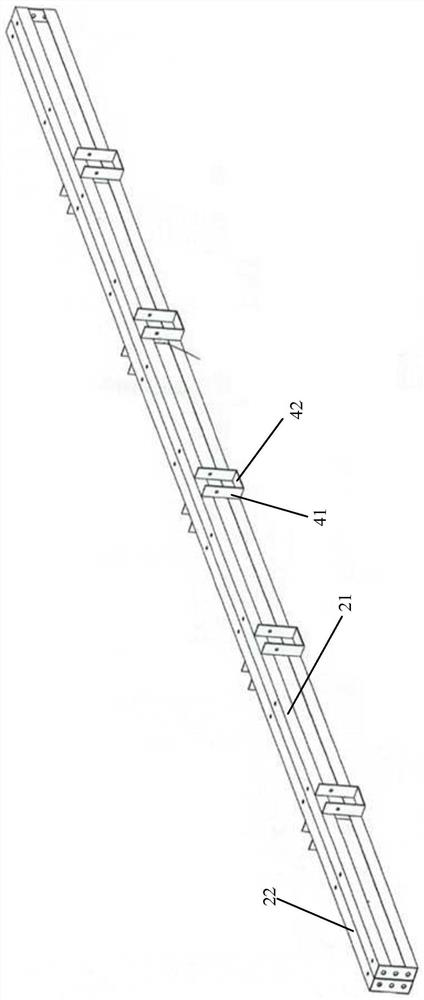

[0028] figure 1 The basic thin-walled steel floor slab layer showing the present invention comprises: a pair of parallel support beams 2, namely located in figure 1 The upper upper support beam 2 and the figure 1 The lower support beam 2 at the lower part; a pair of end support beams 1 arranged at both ends of the pair of parallel support beams 2, namely located in the figure 1 The left end support beam 1 on the left and is located at figure 1 The right end support beam 1 on the right side, the upper support beam 2, the lower support beam 2, the left end support beam 1 and the right end support beam 1 of the present invention constitute the ring beam of the floor layer of the present invention, which is used as a support beam for the floo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap