Water pump fixing support structure capable of adjusting direction of water outlet

A technology for fixing the bracket and the water outlet, which is applied to the arrangement of the cooling combination of the power unit, the components of the pumping device for elastic fluid, the direction of the pump, etc., which can solve the problem that the position and direction of the water outlet of the electric water pump cannot be arranged according to the needs of the whole vehicle. The adjustment and assembly are complicated and time-consuming, and the layout space is large, so as to achieve the effect of simple assembly and time saving, good vibration reduction effect and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

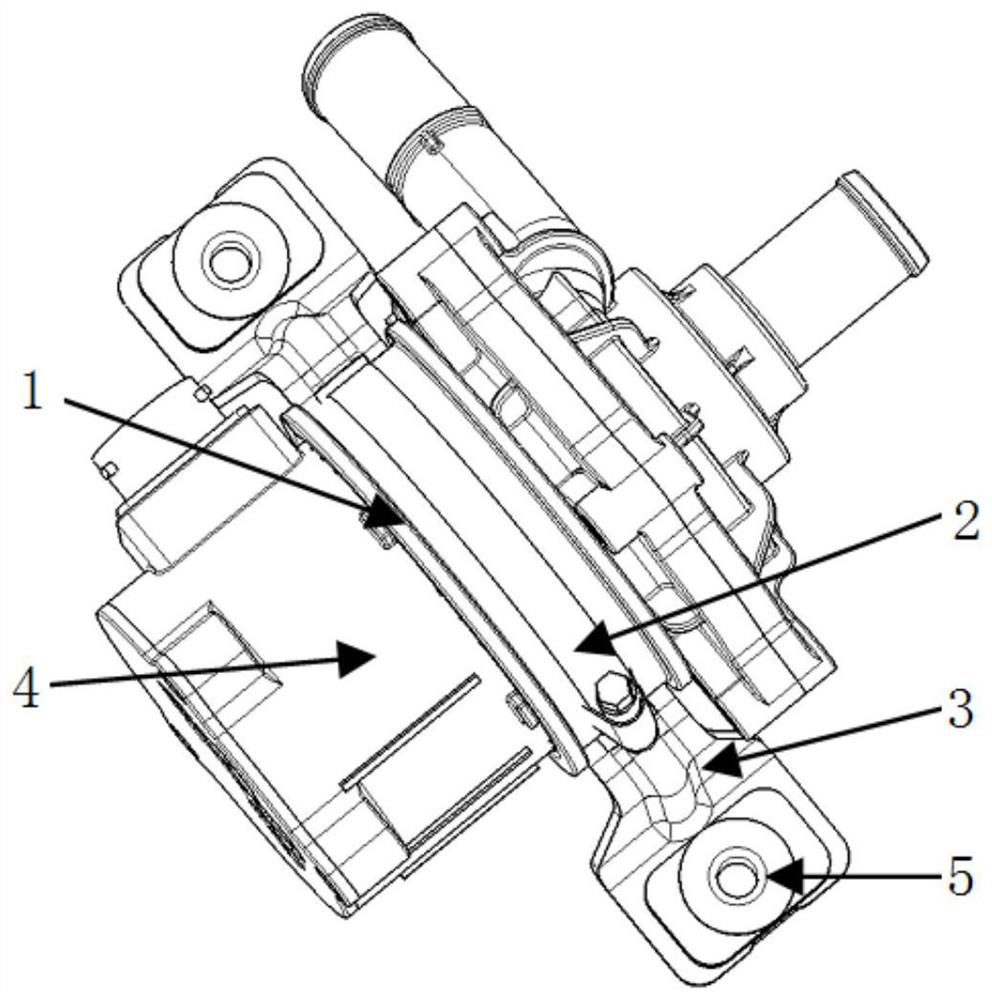

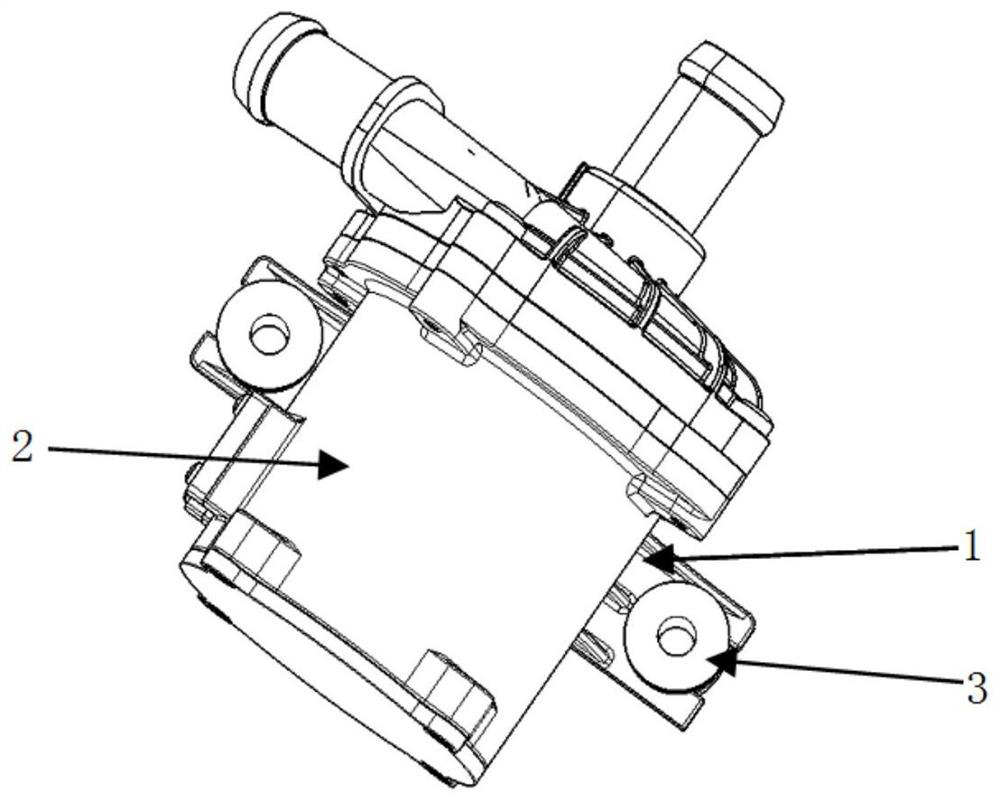

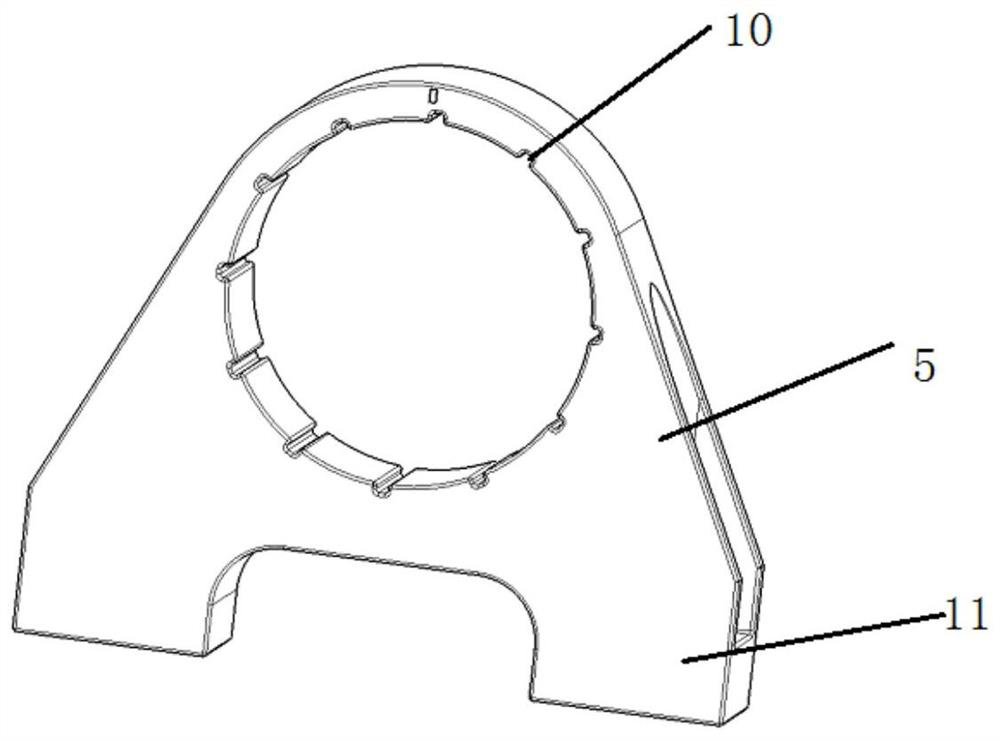

[0027] Figure 3~Figure 7 Among them, the reference signs are respectively: 1. water inlet of water pump; 2. water outlet of water pump; 3. first connecting bolt; 4. water pump shell; Limiting protrusion; 8, second limiting protrusion; 9, third limiting protrusion; 10, limiting slot; 11, leg; 12, inflatable cavity; 13, plug;

[0028] Such as Figure 3~Figure 5 The electric water pump fixing bracket structure that can adjust the direction of the water outlet shown in the figure includes a base body 5 connected to the water pump vehicle bracket, and the base body 5 is provided with a mounting hole 14 that matches the outer peripheral surface of the water pump housing 4 , the axial direction of the mounting hole 14 is consistent with the axial direction of the water pump housing 4; the hole wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com