Simple ion door

An ion gate, a simple technology, applied in the direction of electronic/ion optical devices, particle separator tube parts, etc., can solve the problems of high requirements for assembly personnel and assembly tools, complex ion gate processing, harsh manufacturing conditions, etc., to achieve assembly Simple and time-saving, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

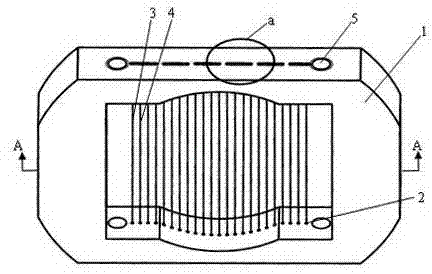

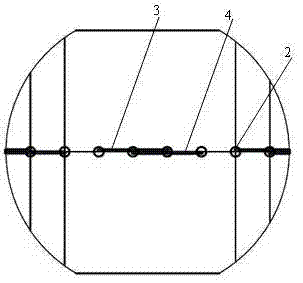

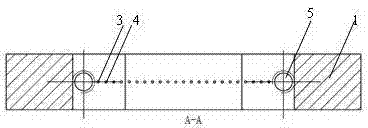

[0016] From figure 1 , figure 2 , image 3 It can be seen from the figure that a simple ion gate is provided with an annular insulating fixing frame 1, and the fixing frame 1 uses polyether ether ketone (PEEK) as the material of the fixing frame. PEEK has good machining performance, high applicable temperature, and can Use in a vacuum. Two sides of the center ring on the fixing frame 1 of the present invention are respectively provided with a plurality of round holes 2, the diameter of the round holes 2 is 0.15 mm, and the distance is 1.0 mm. The circular holes 2 on the said fixed frame 1 are opposite to each other in pairs on both sides of the central ring, and the diameter of the circular holes 2 is slightly larger than the diameter of the enameled wire used. The circular holes 2 are linearly and evenly arranged on the side of the fixed frame 1 , the spacing between the circular holes is even, and all the circular holes 2 are located on the same plane, which is parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com