String tightening method of string tightening type semi-rigid base plate

A semi-rigid, string-stretching technology, applied in the field of frame composite material structure manufacturing, can solve the problems of long measurement period, low tension on the substrate, and cumbersome operation process, so as to avoid a significant drop in tension, improve production efficiency, and simplify the operation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0089] A string stringing method for a string string type semi-rigid substrate, comprising the steps of:

[0090] Step 1: According to the semi-rigid substrate ground test, the actual service space temperature environment and the string tension requirements, formulate the pretreatment process parameters of the aramid braided rope (that is, the string), specifically: the pretreatment temperature is 20% higher than the actual use temperature ℃, the loading load is 20% of the breaking load of the string;

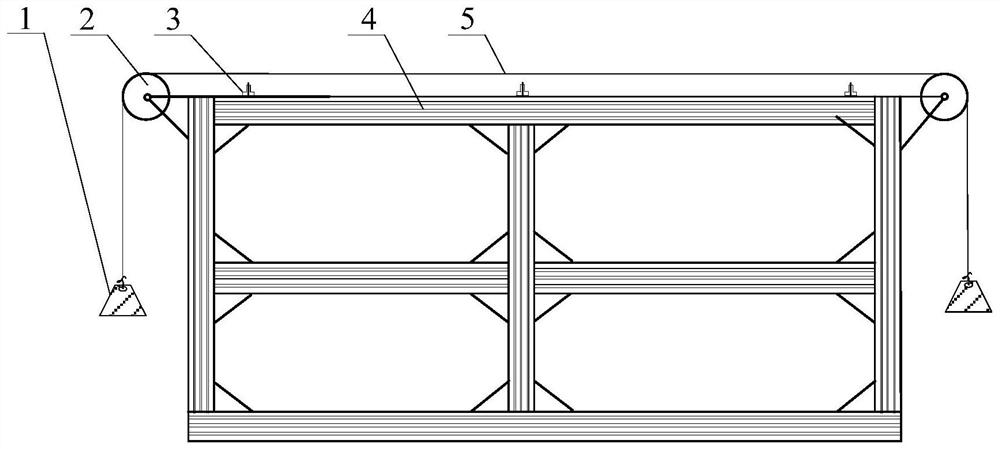

[0091] Step 2: Take 3 pieces randomly from the strings to be treated, install them in the string pretreatment tooling and put them in the oven. The string pretreatment tooling is used to load the strings to be treated, and the process parameters determined in step 1 Carry out pretreatment; Obtain stringing process parts; Stringing pretreatment tooling such as figure 1 shown;

[0092] Step 3: Put the string-stretching craft parts in an airtight container with desiccant, and le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com