Soft package battery side voltage detection device and side voltage detection method

A soft-pack battery and detection device technology, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, can solve the problems of inability to judge the insulation performance and inaccurate test results, and achieve accurate test values, uniform force, and The effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

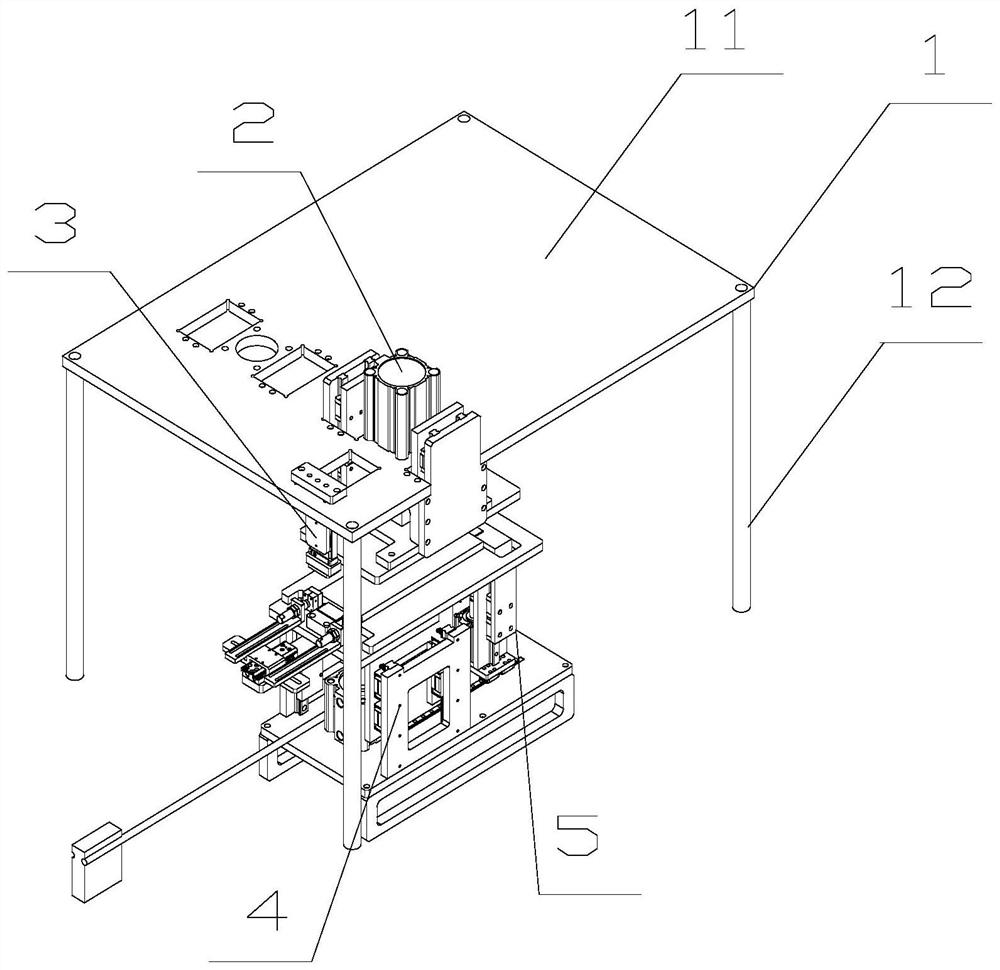

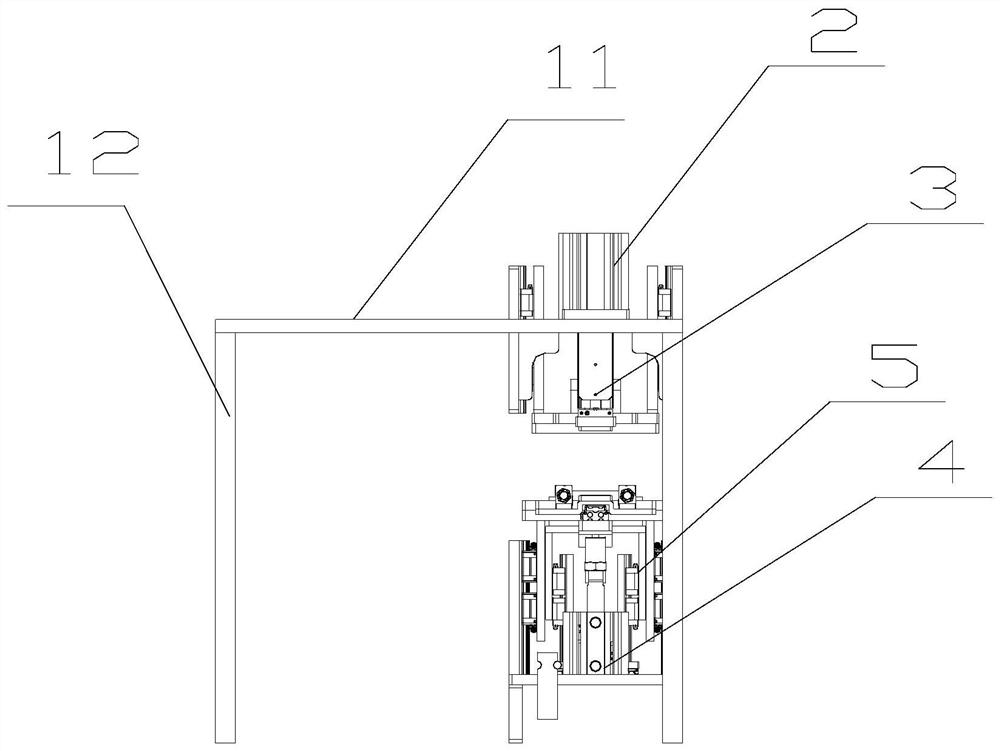

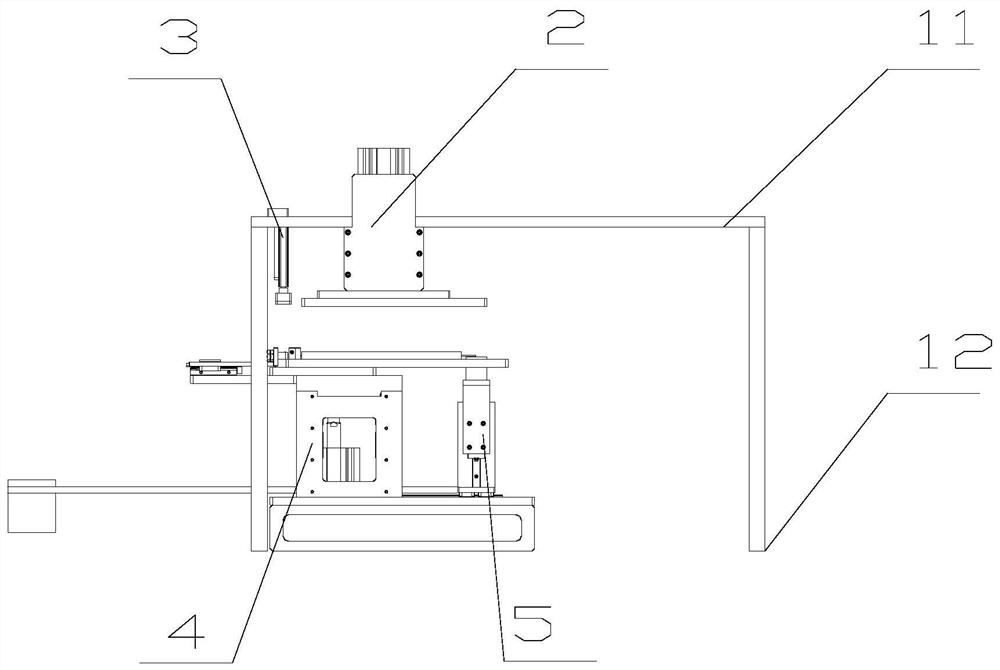

[0043] Embodiment 1 A side voltage detection device of a pouch battery according to the present invention, comprising:

[0044] The support unit 1 is provided with a mounting platform on the top, and the mounting platform is provided with a first hollow mounting hole and a second hollow mounting hole for installing the battery pressing unit and the tab pressing unit;

[0045] The battery pressing unit includes a pressing assembly 2 and an upper pressing assembly 4, the pressing assembly includes a pressing driving mechanism and an upper pressing plate 24, and the driving mechanism is slidably embedded in the first hollow mounting hole of the supporting unit , and keep the force-applying end of the pressing-down driving mechanism protruding from the hollow mounting hole and falling below the mounting table for applying pressure to the pouch battery; the upper pressing plate 24 is installed on the force-applying end of the pressing-down driving mechanism for contacting the pouch ...

Embodiment 2

[0060]Embodiment 2 A side voltage detection device for a pouch battery according to the present invention includes a bracket assembly 1, a battery compression unit, a side voltage detection unit and a control unit, wherein the bracket assembly 1 is used to support the battery compression unit; The battery pressing unit includes a lower pressing assembly 2 and an upper pressing assembly 4. The side voltage detection unit includes a tab pressing conduction mechanism and a tab protection compatible moving mechanism. The tab pressing conducting mechanism includes a pole tab pressing conduction mechanism. The ear pressing assembly 3 and the tab conduction mechanism; the lower pressing assembly 2 is connected to the bracket assembly 1, and is opposite to the upper pressing assembly 4, which is used to press down and stabilize the pouch battery body; the tab pressing assembly 3 is connected to the On the bracket component 1, and adjacent to the pressing component 2, it is used to pres...

Embodiment 3

[0072] Embodiment 3 The method for detecting the side voltage of a pouch battery by using the device for detecting side voltage of a pouch battery described in Embodiment 2 includes the following steps:

[0073] 1) The side voltage detection device of the pouch battery is fixed on the production line through the support base 41 of the bracket assembly 1 and the upper pressure assembly 4;

[0074] 2) After different types of pouch batteries are supplied, the compatible conduction mechanism 46 of the pouch battery side voltage detection device and the tab protection compatible moving mechanism 5 are adjusted according to the size of the incoming pouch battery to meet the actual pouch battery model Size requirements;

[0075] 3) After the photoelectric sensor detects that the pouch battery is loaded in place, the cylinder part 21 of the lower pressing assembly 2 starts to descend. Under the guidance of the first sliding part 22, the upper pressing plate 24 slowly descends, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com