A three-phase thyristor control circuit

A technology of thyristor control and phase thyristor, which is applied in the field of circuits, can solve problems such as large inrush current, electromagnetic interference, and influence on inverter drive, and achieve the effect of protecting devices and reducing inrush current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

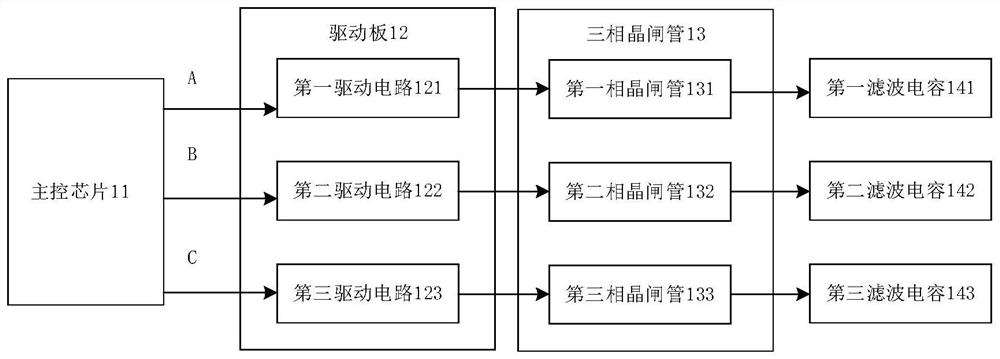

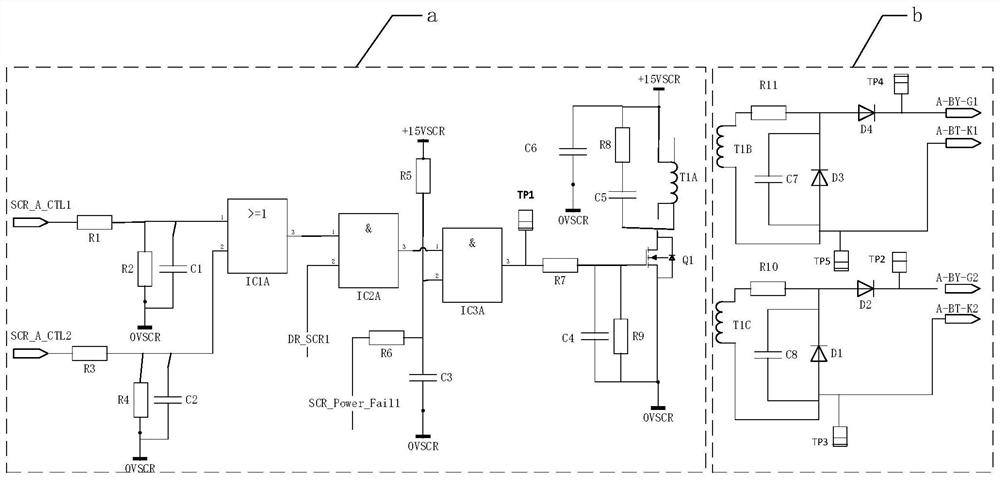

[0042] Embodiments of the present application provide a three-phase thyristor control circuit, such as Figure 1 As shown, the three-phase thyristor control circuit comprising: based on the first master signal A drive first phase thyristor 131 first drive circuit 121; Further, based on the second master signal B to drive the second phase thyristor 132 of the second drive circuit 122; Further, based on the third master signal C drive third phase thyristor 133 third drive circuit 123; And, respectively, the first drive circuit 121, the second drive circuit 122 and the third drive circuit 123 connected to the main control chip 11; The above-described main control chip 11 is configured to transmit the corresponding master signal to the corresponding driving circuit of the target thyristor, wherein the target thyristor is the first phase thyristor 131, the second phase thyristor 132, the third phase thyristor 133, the difference between the input voltage instantaneous value and the outp...

Embodiment 2

[0059] Embodiments of the present application provide a three-phase thyristor control circuit, such as Figure 1As shown, the three-phase thyristor control circuit comprising: based on the first master signal A drive first phase thyristor 131 first drive circuit 121; Further, based on the second master signal B to drive the second phase thyristor 132 of the second drive circuit 122; Further, based on the third master signal C drive third phase thyristor 133 third drive circuit 123; And, respectively, the first drive circuit 121, the second drive circuit 122 and the third drive circuit 123 connected to the main control chip 11; Wherein, the above-described main control chip 11 is configured to: the first phase thyristor 131, the second phase thyristor 132, the third phase thyristor 133 when crossing the zero point to the corresponding thyristor corresponding to the corresponding driver circuit to send the corresponding master signal.

[0060] Since the three-phase thyristor 13 corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com