Manufacturing method for building dry-hanging stone curtain wall keel framework

A technology of dry-hanging stone and its production method, which is applied in the directions of construction, building components, building structure, etc., can solve the problems of time-consuming and laborious manual bending, unqualified bending, deformation of the keel frame of the dry-hanging stone curtain wall, etc. Improve production efficiency and avoid the effect of relative sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

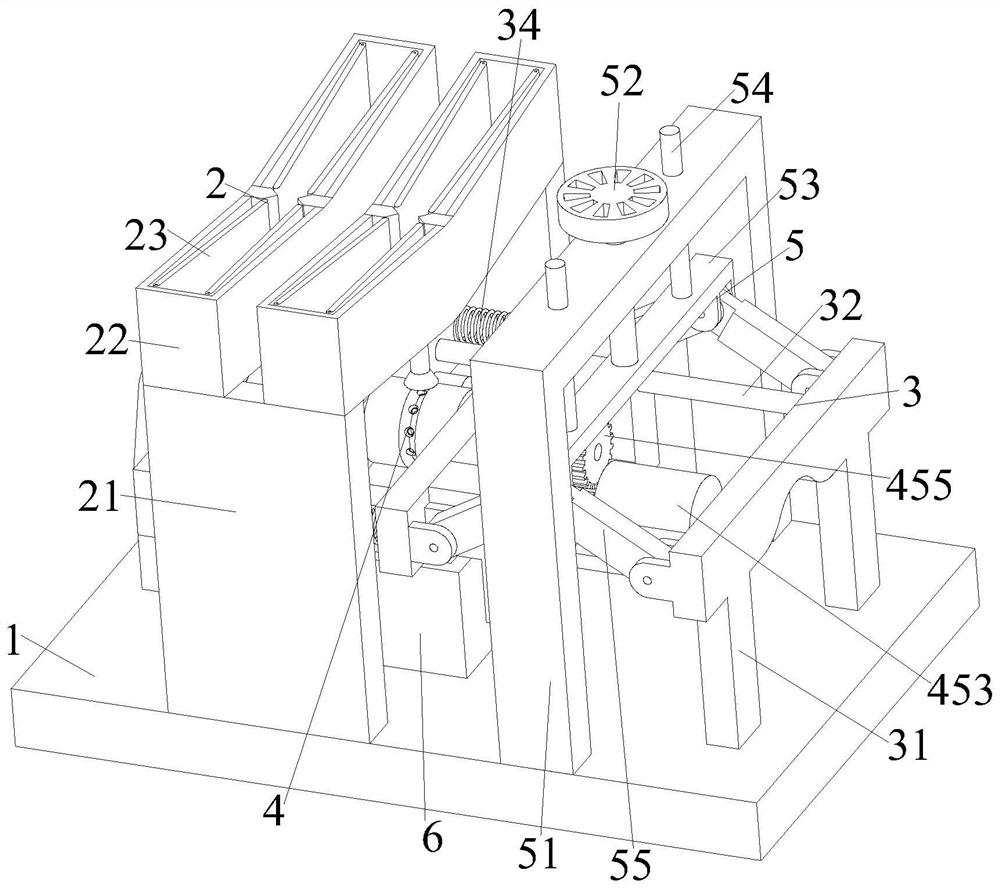

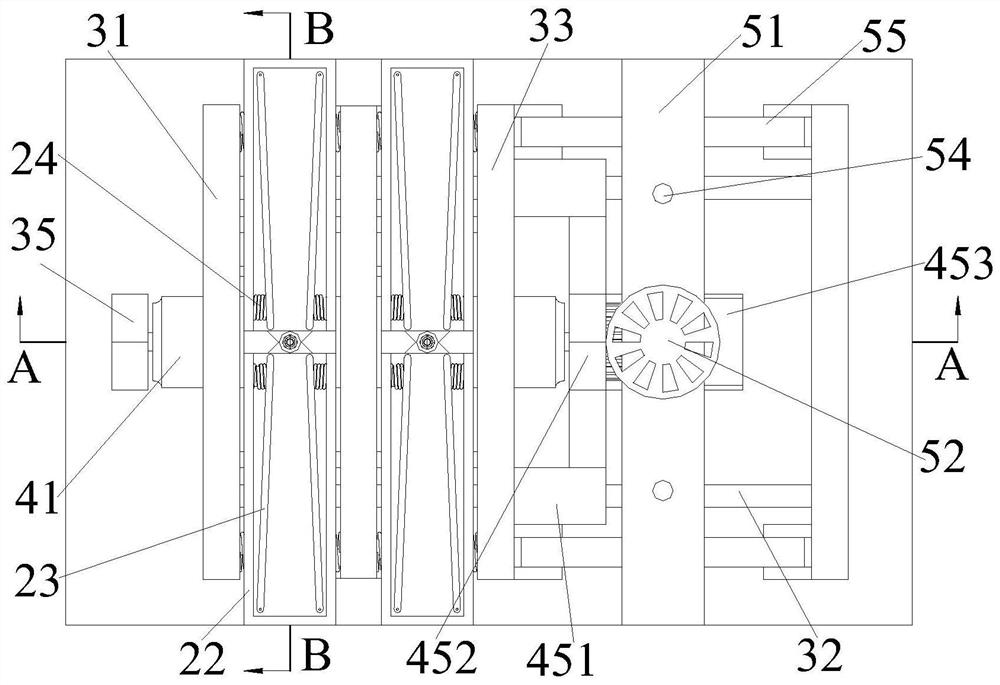

[0038] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 , to further elaborate the present invention.

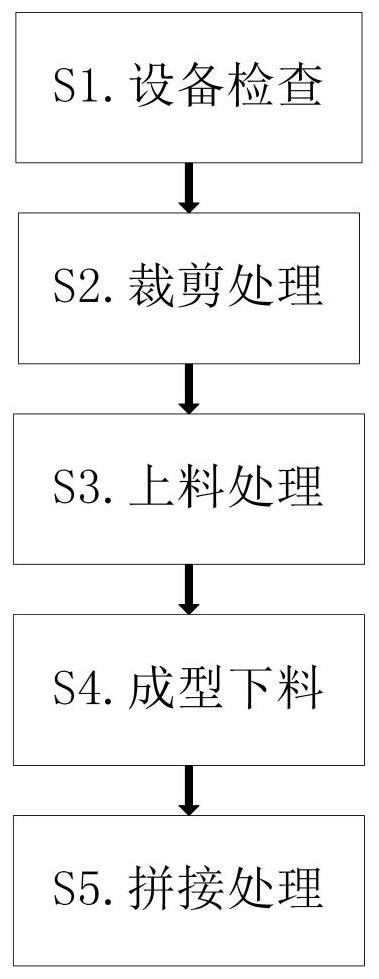

[0039] A method for manufacturing a dry-hanging stone curtain wall keel skeleton, the specific manufacturing method is as follows:

[0040] S1. Equipment inspection: before using the dry-hanging stone curtain wall keel skeleton production equipment to make the dry-hanging stone curtain wall keel skeleton, check it;

[0041] S2. Cutting process: cutting the steel bars into straight steel bars of required length by manual or mechanical means;

[0042] S3. Feeding treatment: after the equipment inspection is completed, manually place the cut straight steel bars in the feeding device 2, so that the feeding device 2 performs feeding processing on the straight steel bars;

[0043] S4. Forming blanking: After the loading is completed, the straight steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com