Manual correction device for coil spring

A manual correction and correction device technology, which is applied in the direction of manufacturing springs from wires, other household appliances, household appliances, etc., can solve problems such as coil springs with unqualified torque and affect product quality, and achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

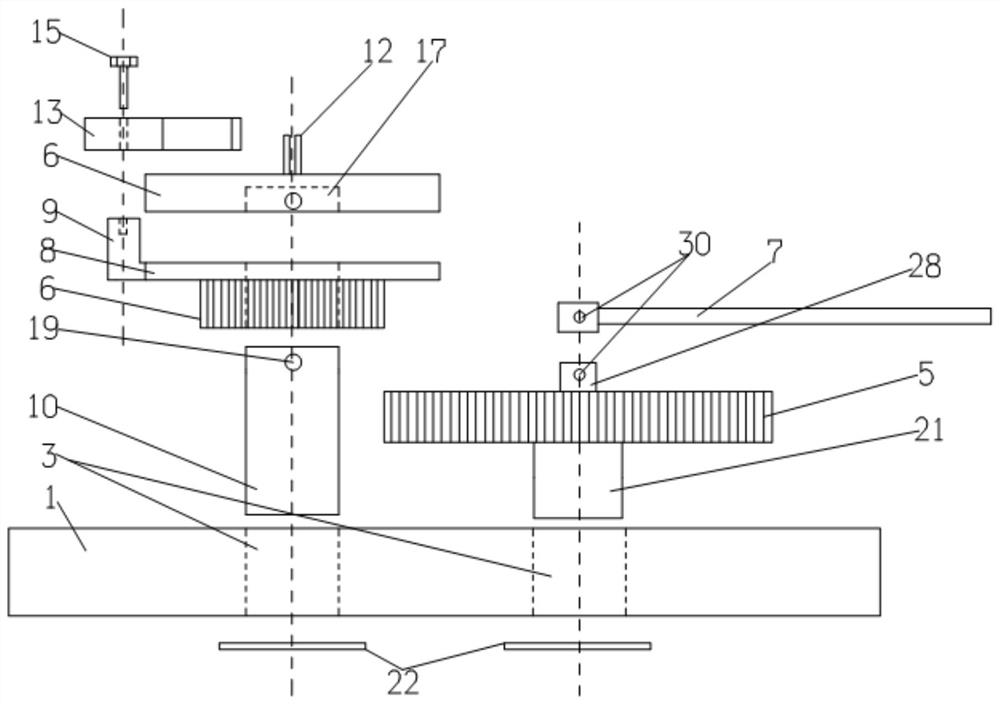

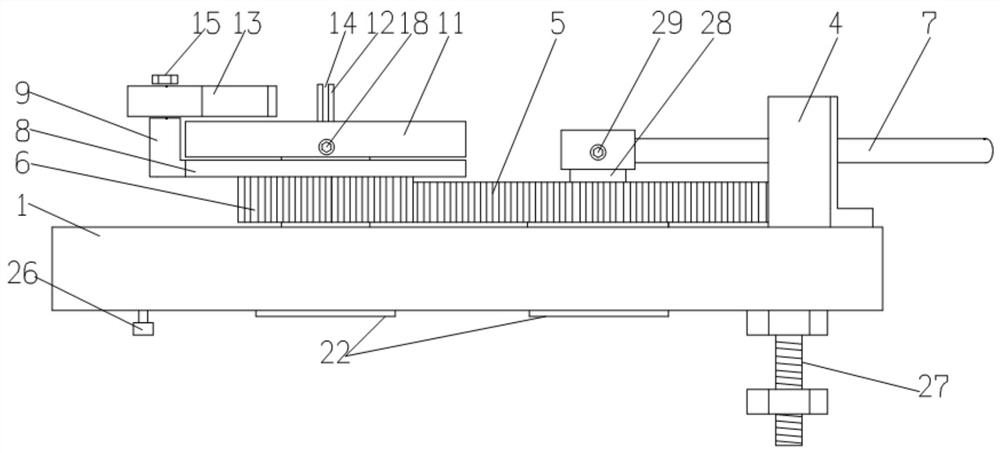

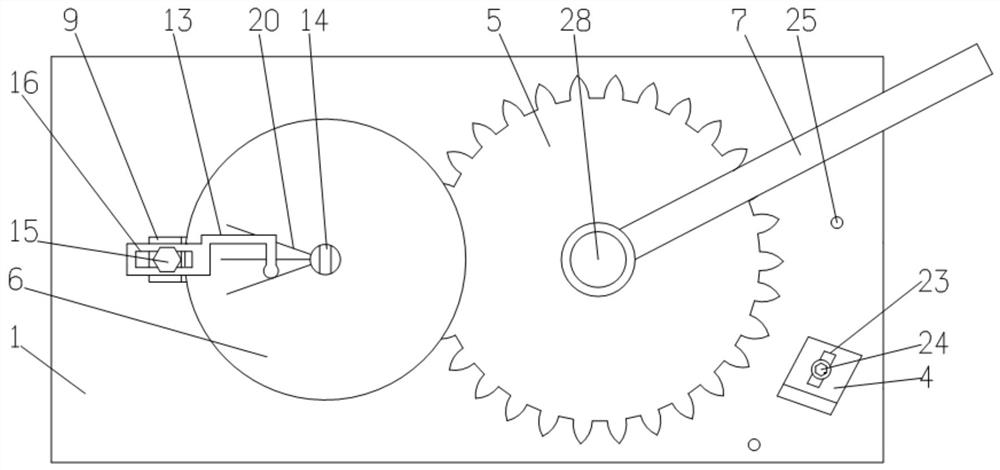

[0034]Example: seefigure 1 ,figure 2 ,image 3 ,Figure 4 ,Figure 5 ,Figure 6 ,Figure 7 ,Figure 8 ,Picture 9 withPicture 10, In the figure, 1- bottom plate, 2- coil spring, 3- through hole, 4- limit stop, 5- driving gear, 6-driven gear, 7-handle, 8-disc, 9-bracket, 10 -Fixed shaft, 11-Fixed plate, 12-Locating shaft, 13-Fixed plate, 14-Through slot, 15-Connecting bolt, 16-First strip hole, 17-Counter hole, 18-First fixing bolt, 19 -The first fixing hole, 20-scale line, 21-rotation shaft, 22-fixing block, 23-second strip hole, 24-limit bolt, 25-limit screw hole, 26-support bolt, 27-fix bolt , 28- connecting shaft, 29- second fixing bolt, 30- second fixing hole.

[0035]The manual correction device for the coil spring includes a bottom plate, a rotating device and a correction device. The correction device is arranged on the bottom plate by the rotating device, and the correction device is driven to rotate by the rotating device to realize the correction operation of the coil spring; the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com