A paper tape rectification control device and rectification method

A paper tape and controller technology, which is applied in the paper tape deviation correction control device and the paper tape deviation correction field, can solve the problems affecting the precision production equipment continuity of the strip processing, the overprint deviation of the printing pattern, and the irregular edge of the strip, etc., to achieve Easy to expand the use of functions, fast response, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] specific implementation

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

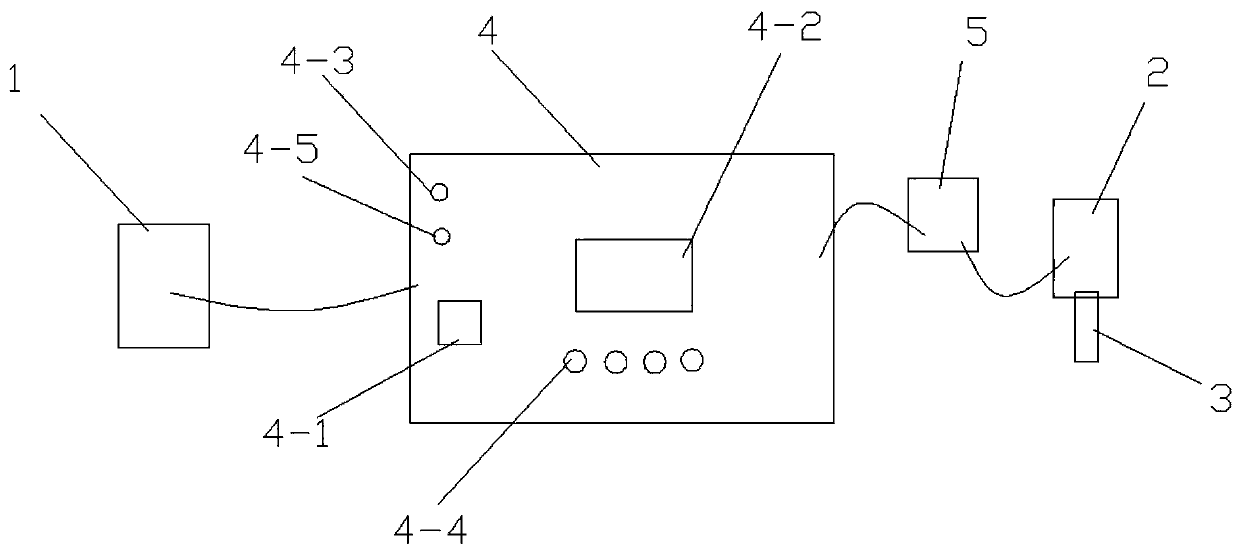

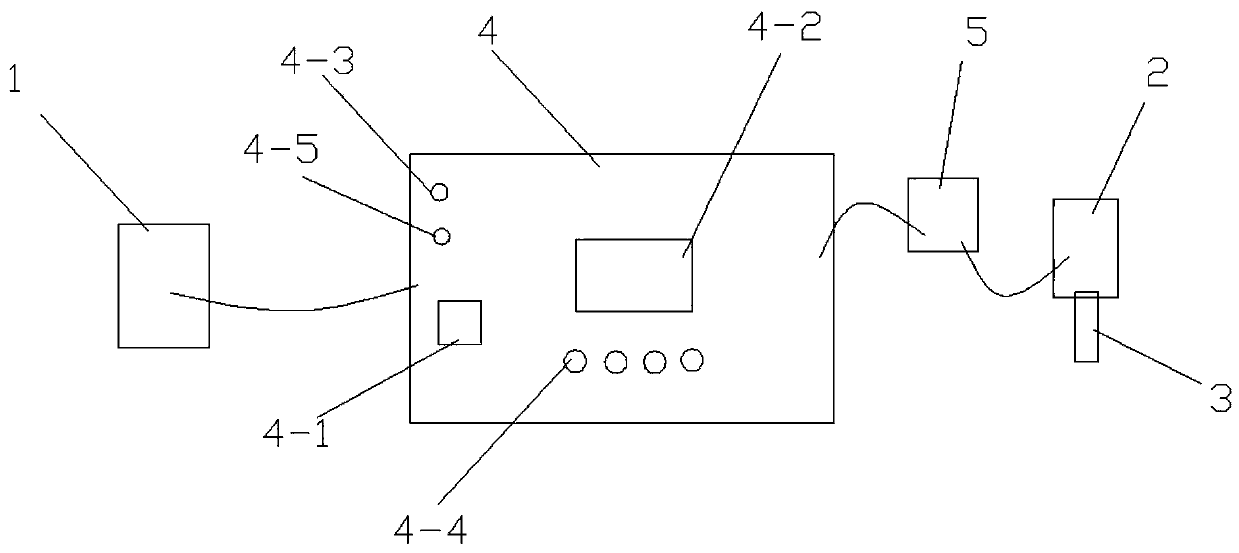

[0038] A paper tape deviation correction control device of the present invention, such as figure 1 As shown, it includes an ultrasonic sensor 1, the ultrasonic sensor 1 is connected with a control system 4, the control system 4 is connected with a stepper motor driver 5, the stepper motor driver 5 is connected with a stepper motor 2, and the output shaft of the stepper motor 2 is connected with a Ball screw 3.

[0039] The control system 4 comprises a controller 4-1, and the controller 4-1 is connected with a liquid crystal display 4-2, a communication module, a first indicator light 4-3, a second indicator light 4-5 and a reset switch 4-4; Switch 4-4 is connected with stepping motor 2.

[0040] The model number of the ultrasonic sensor 1 is AE-210.

[0041] The controller 4-1 is a chip of model STC12C5A60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com