Suspension cable-arch combined system bridge structure and assembly construction method thereof

A technology for bridge structure and arch structure, applied in the field of suspension cable-arch composite system bridge structure and its assembly construction, can solve the problems of complicated construction and waste of resources, and achieve the beneficial effects of reducing erection, saving resources and controlling construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below with reference to the accompanying drawings.

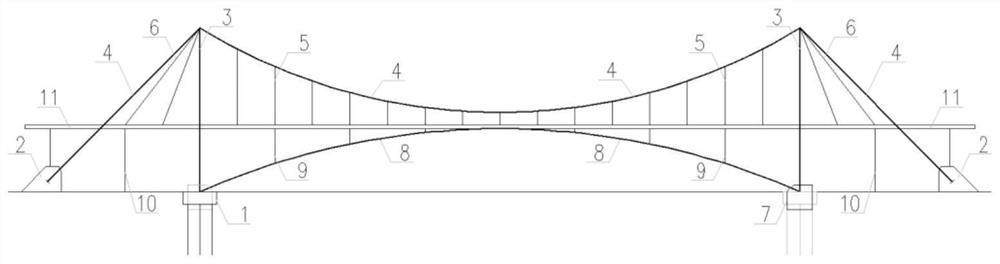

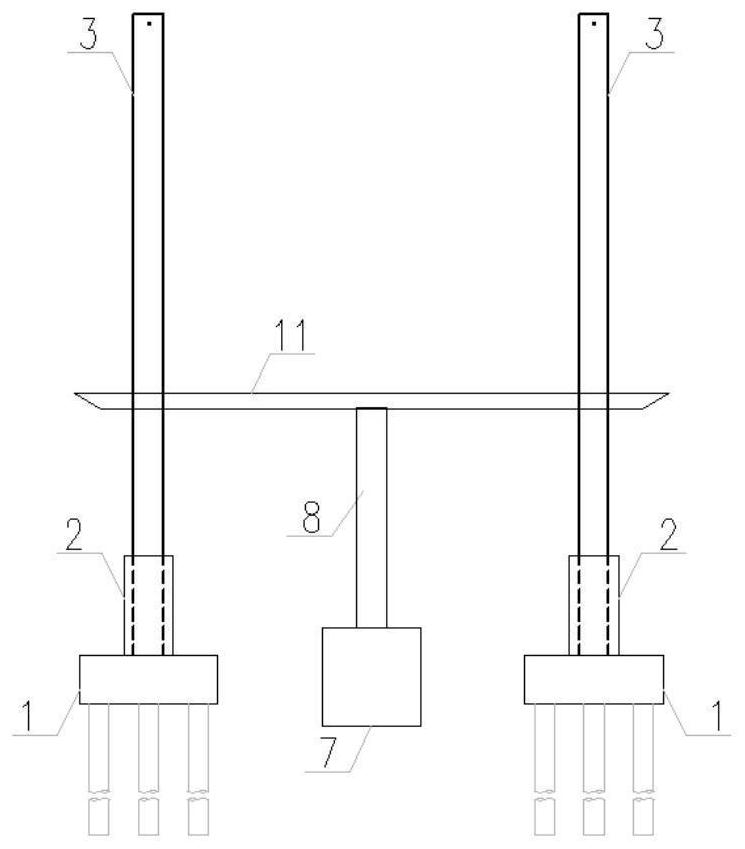

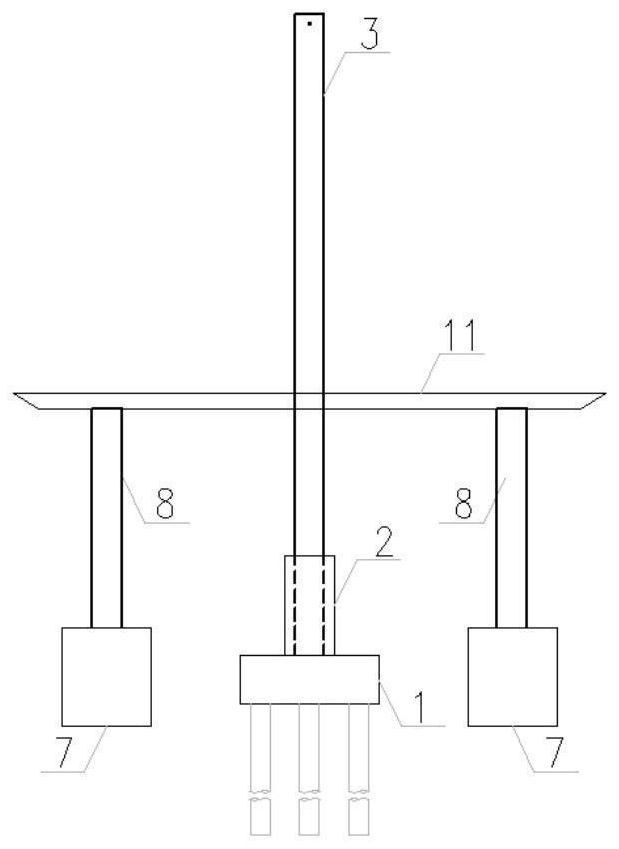

[0035] refer to figure 1 , figure 2 and image 3 , A suspension cable-arch composite system bridge structure, an arch rib is arranged below the main beam 11 of the suspension bridge, an arch upper column 9 is arranged on the arch rib, the upper end of the arch rib column 9 is connected to the main beam 11, and the lower end of the arch rib column is connected to the arch rib , both ends of the arch rib are fixed on the arch rib foundation, the arch rib foundation 7 adopts an independent foundation, and the arch rib foundation 7 is arranged under the main beam; the arch rib includes several prefabricated arch rib segments, and the prefabricated arch rib segments are fixed between The connection adopts prefabricated assembly construction; arch rib 8 The main arch and the main cable surface are not coplanar; the arch rib can cooperate with the cable system to bear the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com