Fiber reinforced concrete frame structure

A fiber-reinforced and frame-structured technology, which is applied in building construction and construction, can solve the problems of inability to modularize production and low production efficiency, and achieve the effects of strong practicability, convenient transportation and strong ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

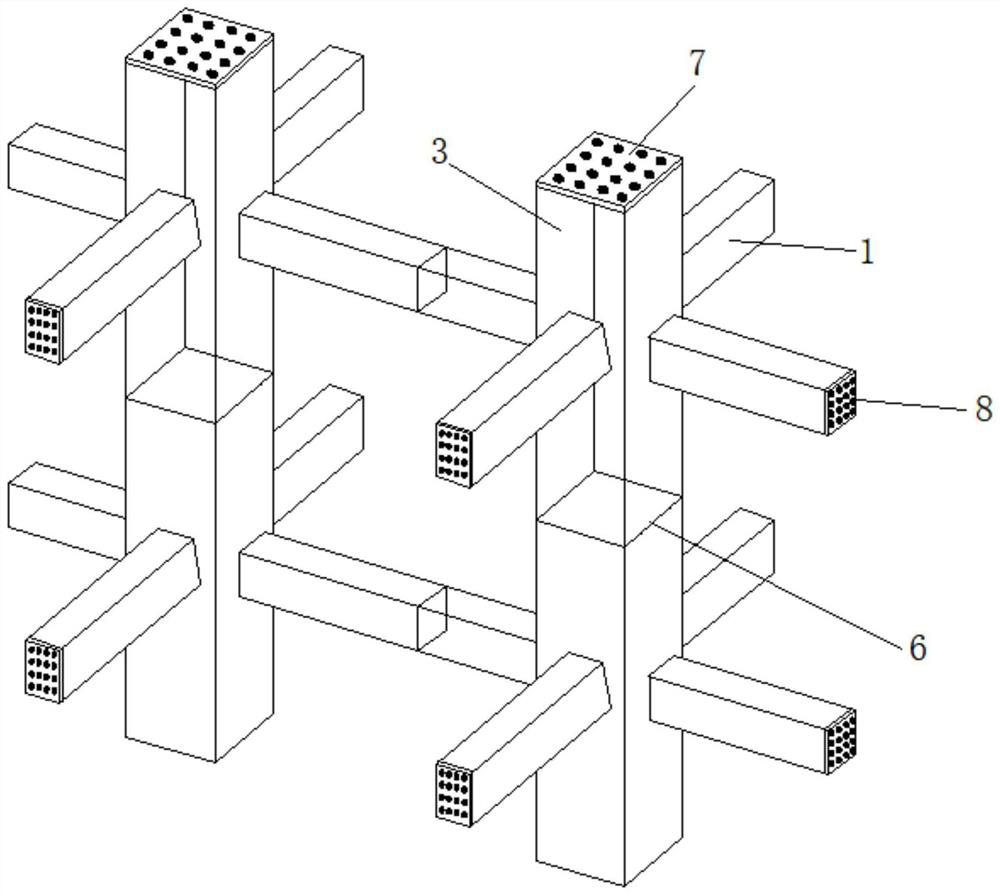

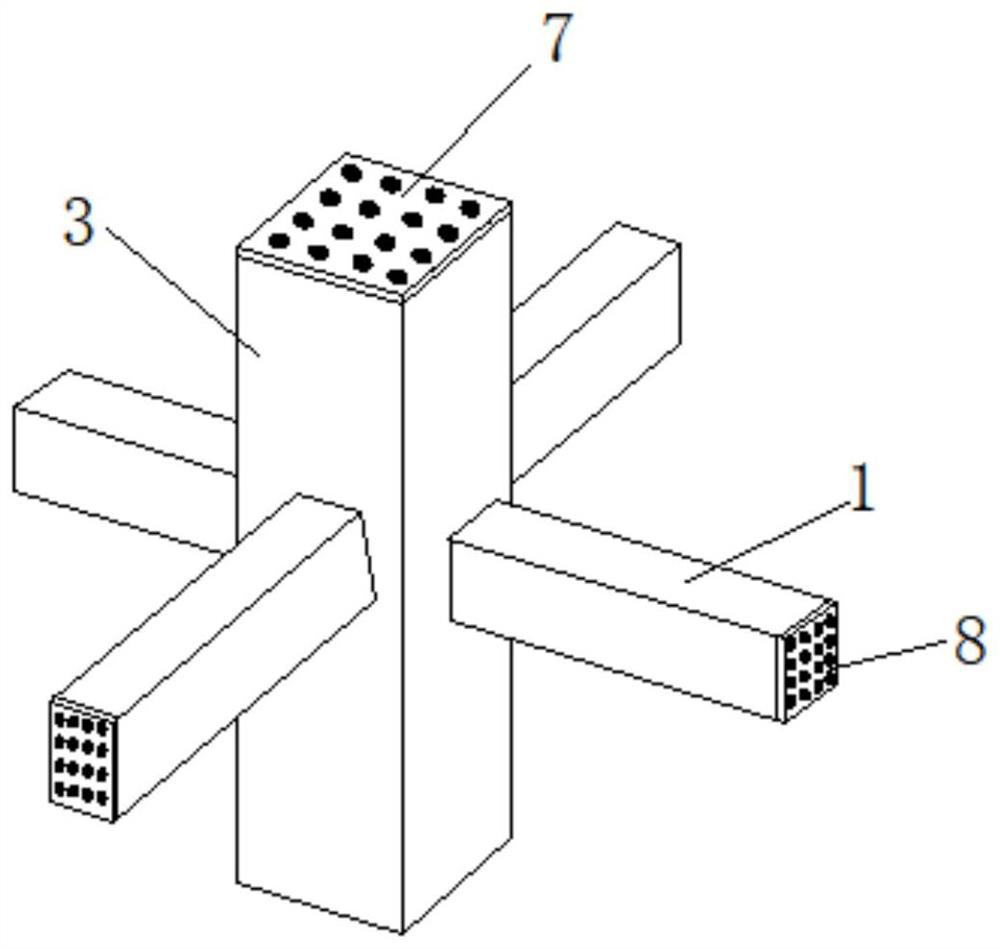

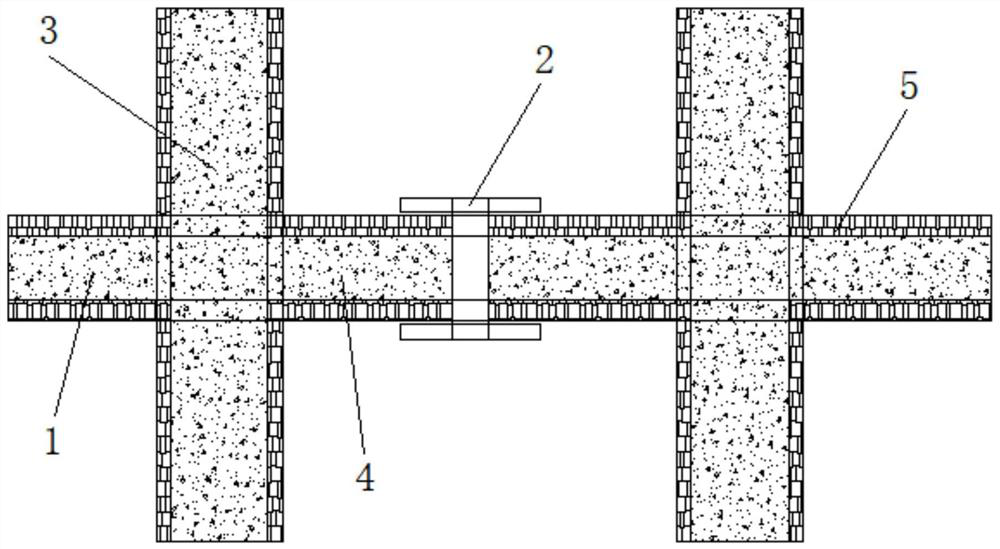

[0027] The invention provides a fiber reinforced concrete frame structure, specifically as Figure 1 to Figure 4 As shown, it includes multiple frame units connected by multiple steel cages, and the modular setting is more convenient for transportation and installation; each frame unit includes multiple crossed and vertically arranged concrete beams 1, concrete columns 3, and concrete The beam 1 and the concrete column 3 are composed of a steel cage and concrete 4 poured in the steel cage; the surface of the concrete beam 1 and the concrete column 3 are fixed and clamped by the anchor 2 to hold the prestressed fiber reinforced composite sheet 5, and the clamped anchor 2 is connected with the steel cage, and the junction of the concrete beam 1 and the concrete column 3 forms a reinforced concrete node 6; by setting the prestressed fiber reinforced composite sheet 5 on the surface of the concrete beam 1 and the concrete column 3, the strength of the entire frame is greatly improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com