Connecting structure and connecting method for parts at thin plate of atomizing and cooling dust remover

A connection structure and dust collector technology, applied in the direction of thin plate connection, connecting components, threaded fasteners, etc., can solve the problems of mechanical properties and sealing, the displacement of the center position of nuts and holes, and large-area deformation of plates. Achieve the effect of smooth and beautiful overall structure, reduce the workload of assembly and reduce the workload of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

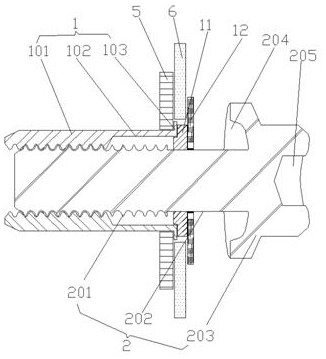

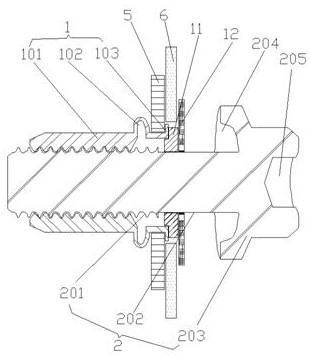

[0041] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

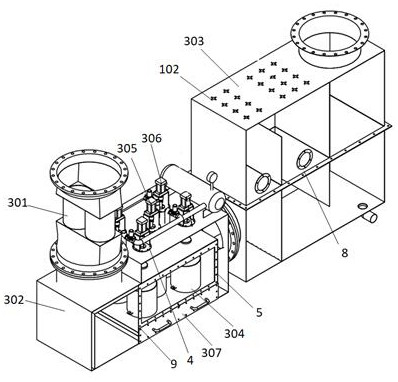

[0042] refer to Figure 1-7 , a connection structure of components at the thin plate of a spray cooling dust collector, including a blind rivet nut 1 and a blind rivet screw 2, the spray cooling dust collector specifically refers to a three-way catalytic converter 301, a pulse regeneration carbon black particle collection box 302 and The cooling horizontal spray box 303 is an integrated shell structure, the pulse regeneration carbon black particle collection box 302 is equipped with a DPF particle trap tank 304, and the top outlet of the DPF particle trap tank 304 is equipped with The lifting valve 305 and the blowback valve 306, the bottom outlet of the DPF particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com