Control method for multi-point sampling and accurate ammonia spraying

A control method and precise technology, applied in the direction of sampling devices, separation methods, chemical instruments and methods, etc., can solve the problems of air preheater blockage, chimney outlet exceeding the standard, and will not improve the denitrification efficiency, so as to achieve precise ammonia injection and realize Energy saving and emission reduction, improving reliability and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

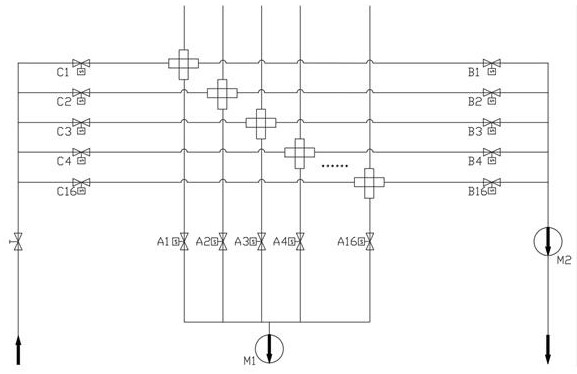

[0022] Based on the above method, the air flow process for setting the SCR structure is as follows: figure 1 As shown, the flue is divided into 16 areas, C1~C16 is the blowback system, B1~B16 is the pre-sampling system, A1~A16 is the measurement system, and the three systems are connected to the flue through a four-way valve to form a set. Complete multi-point sampling system. The multi-point sampling system sends the flue gas to the CEMS system. The CEMS system can be an infrared or ultraviolet analyzer to analyze the nitrogen oxides and oxygen content in the flue gas. The workflow is as follows:

[0023] The pre-sampling system starts, the solenoid valve at point B1 opens, and the M2 sampling pump performs sampling to fully discharge the flue gas from the sampling pipe; the A16 solenoid valve opens, the M1 sampling pump starts, and the first invalid data measurement is performed; 180s later A1, B2, C16 The solenoid valve at point A16 and B1 is closed, the point B2 is pre-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com