Room-temperature tensile test method for high-strength steel

A tensile test and high-strength steel technology, which is applied in the field of room temperature tensile test of high-strength steel, can solve the problems of large dispersion of values, inconsistent curvature of the elastic section of the tensile curve, and non-conformity, and achieves reliable data support and simple test methods. convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

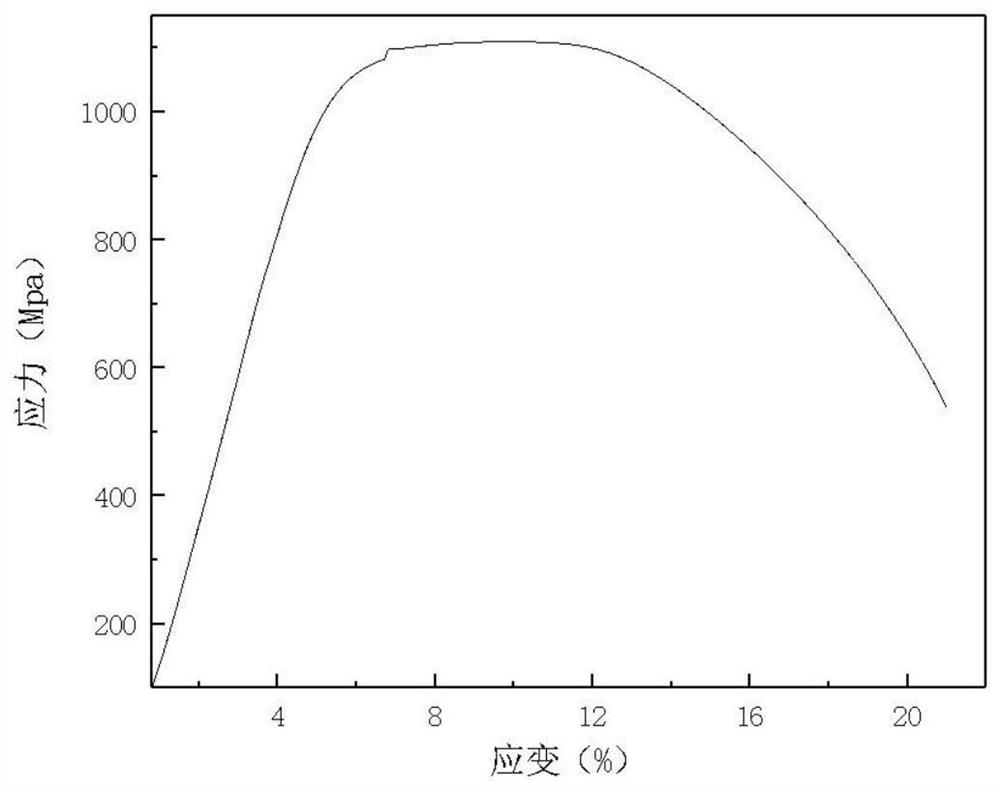

[0049] The invention provides a room temperature tensile test method for the specified plastic elongation strength of high-strength steel (13Cr4Ni), and its process parameters are:

[0050] The beam displacement rate is 0.5mm / min. The starting point of the hysteresis ring exceeds the strength when the material is expected to yield, and is lower than the expected specified plastic extension strength value, and the reverse point under the hysteresis ring is the starting value of 10%.

[0051] The test temperature of the tensile test is 25°C.

[0052] Using the Zwick Z050 testing machine, the starting point of the hysteresis loop is set to 830MPa, and the reverse point of the hysteresis loop is set to 83MPa.

[0053] Start the test. After the sample is loaded to the starting point of the hysteresis ring at the beam displacement rate of 0.5mm / min, it is unloaded at the same rate. Variable speed (3.5mm / min) until the sample breaks.

[0054] Figure 7 As shown, the hysteresis lo...

Embodiment 2

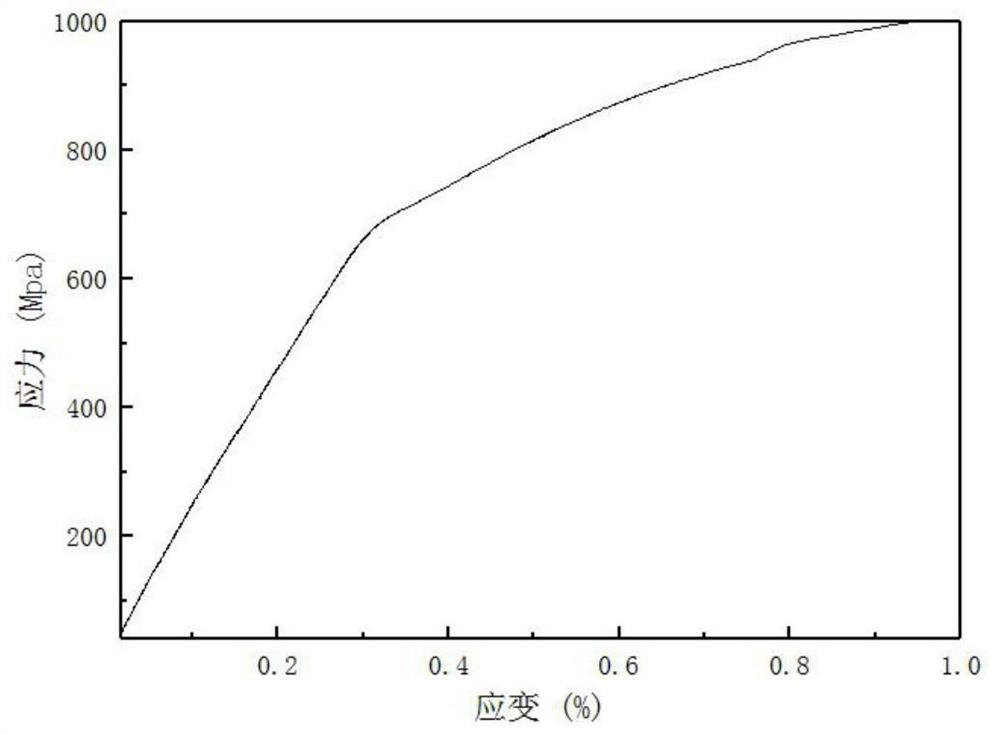

[0058] The invention provides a room temperature tensile test method for the specified plastic elongation strength of high-strength steel (13Cr4Ni), and its process parameters are:

[0059] The beam displacement rate is 0.5mm / min. The starting point of the hysteresis ring exceeds the strength when the material is expected to yield, and is lower than the expected specified plastic extension strength value, and the reverse point under the hysteresis ring is the starting value of 10%.

[0060] The test temperature of the tensile test is 25°C.

[0061] Using the Zwick Z050 testing machine, the starting point of the hysteresis loop is set to 860MPa, and the reverse point of the hysteresis loop is set to 86MPa.

[0062] Start the test. After the sample is loaded to the starting point of the hysteresis ring at the beam displacement rate of 0.5mm / min, it is unloaded at the same rate. Variable speed (3.5mm / min) until the sample breaks.

[0063] Figure 8 As shown, the hysteresis lo...

Embodiment 3

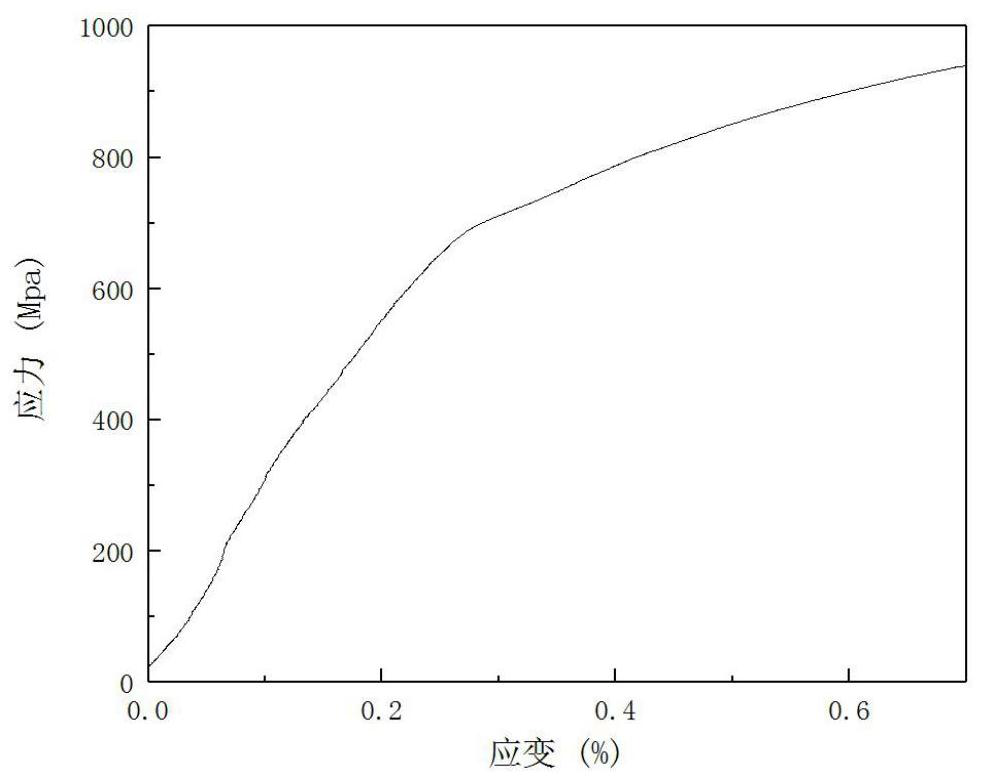

[0067] The invention provides a room temperature tensile test method for the specified plastic elongation strength of high-strength steel (13Cr4Ni), and its process parameters are:

[0068] The beam displacement rate is 0.5mm / min. The starting point of the hysteresis ring exceeds the strength when the material is expected to yield, and is lower than the expected specified plastic extension strength value, and the reverse point under the hysteresis ring is the starting value of 10%.

[0069] The test temperature of the tensile test is 25°C.

[0070] Using the Zwick Z050 testing machine, the starting point of the hysteresis loop is set to 890MPa, and the reverse point of the hysteresis loop is set to 89MPa.

[0071] Start the test. After the sample is loaded to the starting point of the hysteresis ring at the beam displacement rate of 0.5mm / min, it is unloaded at the same rate. Variable speed (3.5mm / min) until the sample breaks.

[0072] Figure 9 As shown, the hysteresis lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com