Forward wave directional coupler based on microstrip lines and substrate integrated waveguide structure

A substrate-integrated waveguide and directional coupler technology, applied in waveguide devices, electrical components, connection devices, etc., to achieve the effects of low cost, high application frequency, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments.

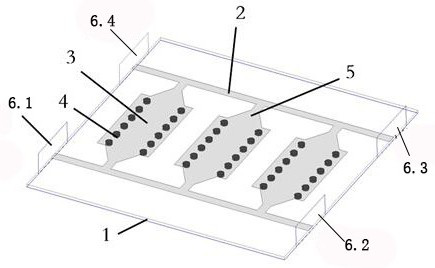

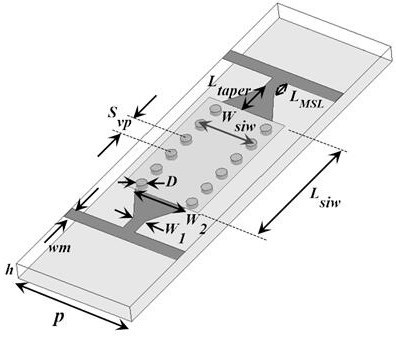

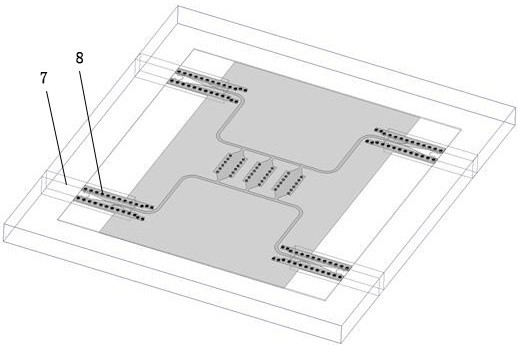

[0023] A forward wave directional coupler based on a microstrip line and a substrate integrated waveguide structure, characterized in that it includes a double-sided substrate 1, and two microstrip lines 2 are arranged on the surface of the double-sided substrate 1, The two microstrip lines 2 are parallel to each other, a number of substrate integrated waveguides 3 are arranged between the two microstrip lines 2, and the ends of the substrate integrated waveguides 3 are connected to the adjacent microstrip lines 2 A triangular microstrip transition section 5 is arranged between them, and a plurality of integrated waveguide short-circuit via holes 4 are arranged on both sides of the substrate integrated waveguide 3;

[0024] The ends of the two microstrip lines 2 respectively form an input port 6.1, a through port 6.2, a coupling port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com