Production device for producing sandwich bread

A production device, a technology for sandwich bread, applied in the directions of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of large space and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

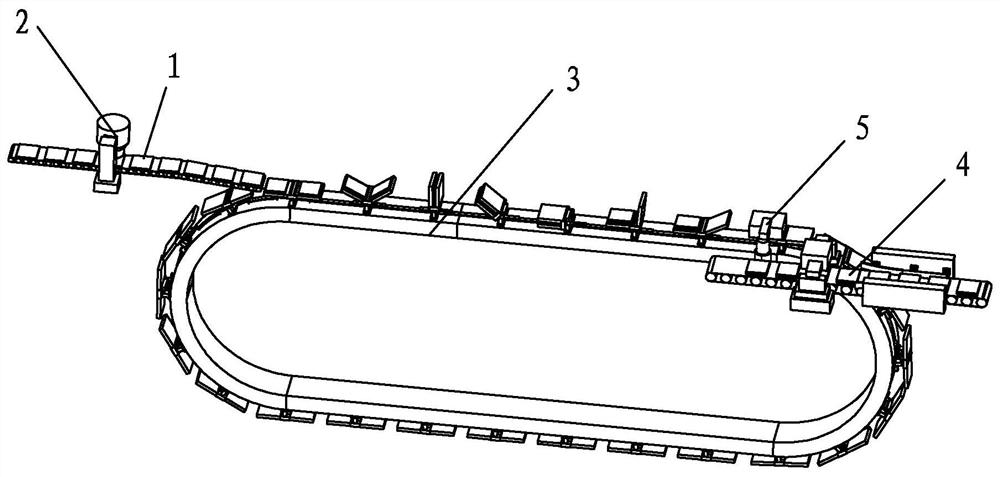

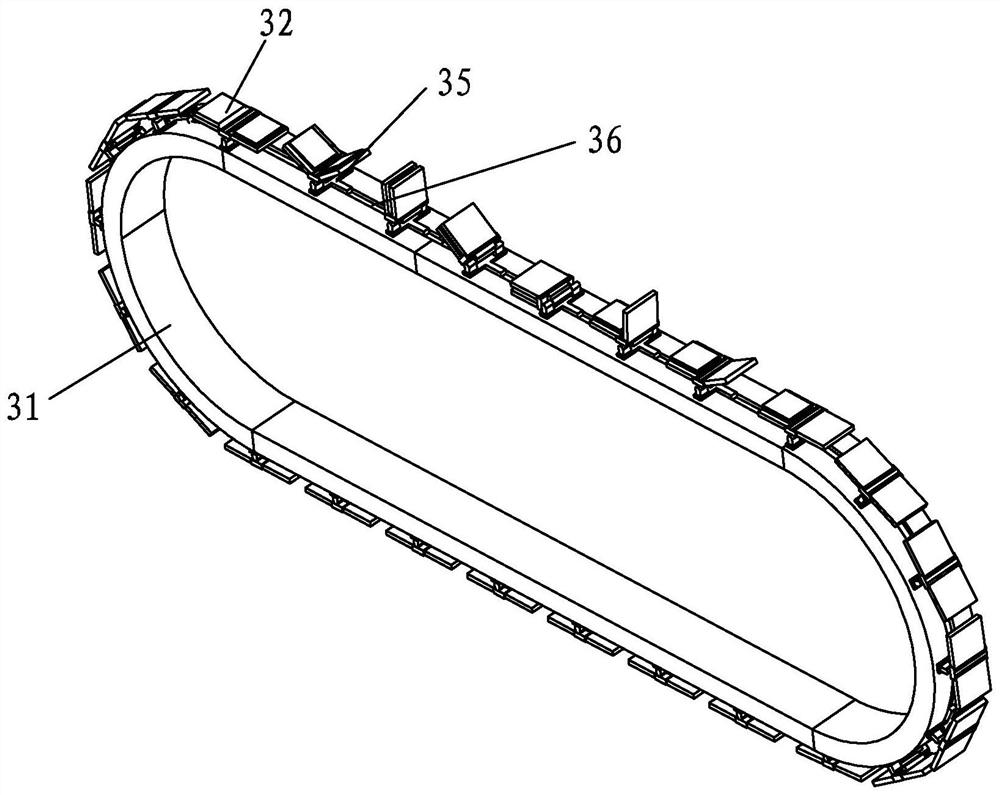

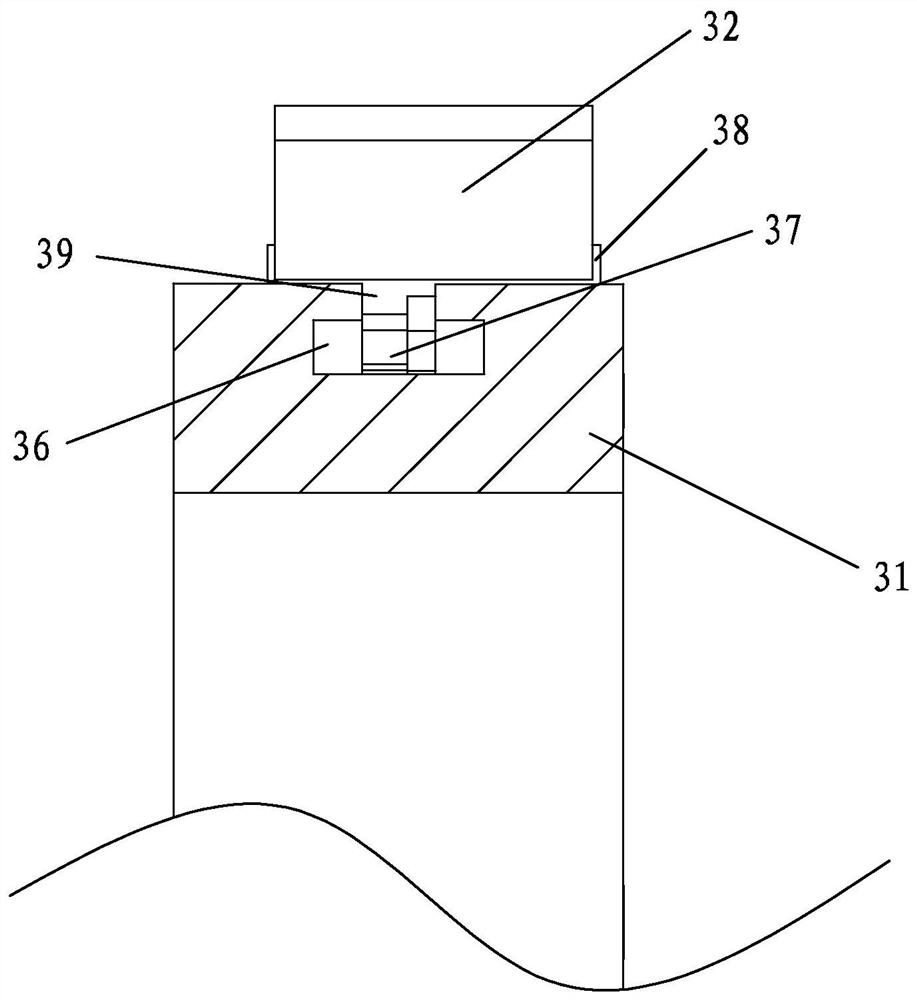

[0045] A kind of production device of producing sandwich bread of the present invention, as Figure 1-Figure 7 As shown, it includes a first conveying device 1 for conveying slices of bread, a sandwich extruder 2 located on the first conveying device 1 to extrude the sandwich material toward the slices of bread, and a sandwich extruder 2 located at the output end of the first conveying device 1 for stacking and forming bread Transmission stacking device 3, and the second transmission device 4 that conveys complete bread; Transmission stacking device 3 comprises transmission track 31, and surrounds transmission track 31 and moves the stacking assembly 32 that is arranged on transmission track 31; Stacking assembly 32 includes respectively placing bread The first superimposing plate 33 and the second superimposing plate 34 arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com