Mixing device for glue production

A mixing device and glue technology, used in mixers, transportation and packaging, shaking/oscillating/vibrating mixers, etc., can solve the problems of single mixing method and poor mixing effect, and improve safety and facilitate manual operation. Open, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

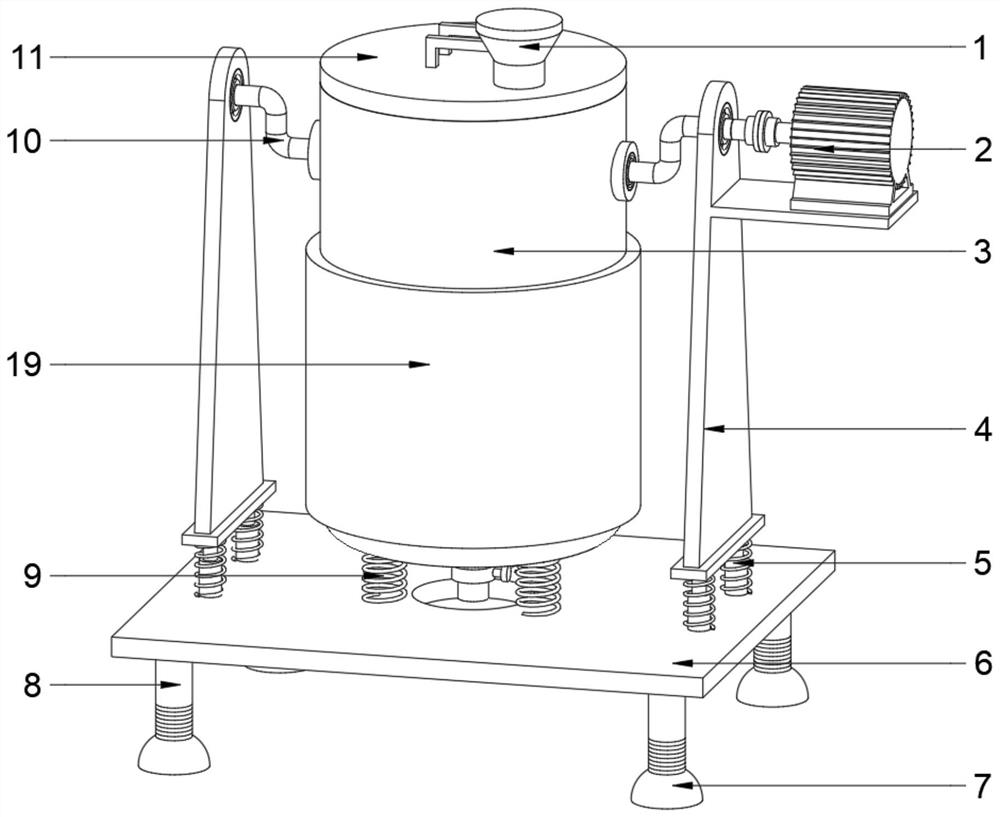

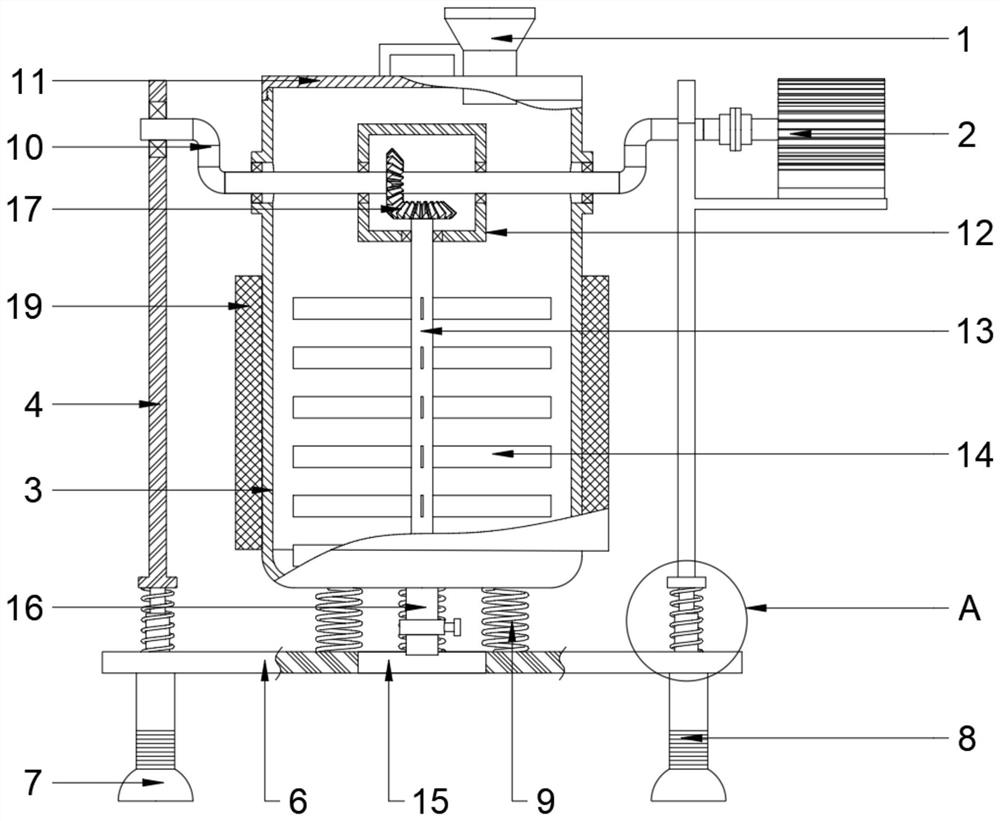

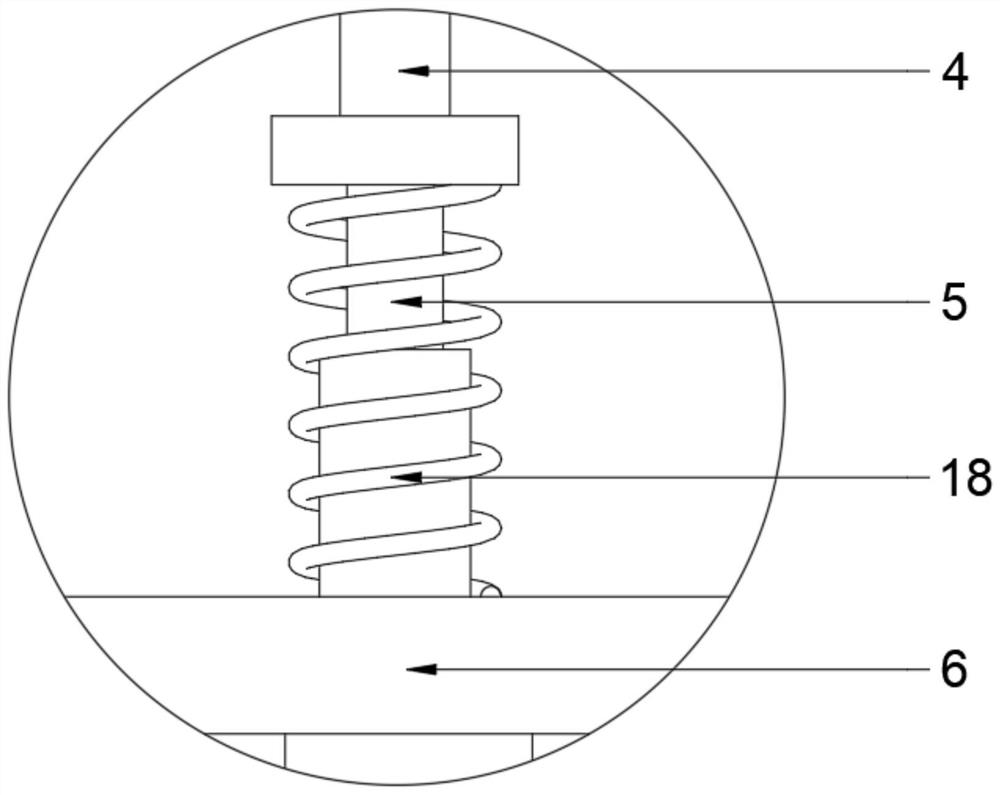

[0025] see Figure 1~3 , in an embodiment of the present invention, a mixing device for glue production, comprising a mixing frame and a mixing tank 3 and a mixing device installed on the mixing frame, the mixing frame includes a support frame 4 and The frame bottom plate 6, the number of the support frame 4 is two groups and is installed on the frame bottom plate 6 by a shaking device, the mixing bucket 3 is installed on the support frame 4 by a mixing device and a heating device 19 is arranged on its periphery , the top of the mixing tank 3 is also communicated with a feed hopper 1, through which materials are added to the inside of the mixing tank 3; the mixing device includes a drive crankshaft 10, a conversion shell 12 and a stirring shaft 13. The mixing tank 3 is connected in rotation with the transmission crankshaft 10, and the two ends of the transmission crankshaft 10 are mounted on two sets of support frames 4 through bearings, and one end of the transmission cranksh...

Embodiment 2

[0032] see figure 1 , 2 , 4. In the embodiment of the present invention, a mixing device for glue production, in order to prevent the mixing tank 3 from deflecting during work and affecting the work of the mixing device, on the basis of Example 1, the mixing tank 3. The bottom is also provided with limit springs 9. The number of the limit springs 9 is three groups and is evenly distributed in the periphery of the discharge port 15 in a ring shape. The three sets of limit springs 9 are fixed at one end away from the mixing barrel 3 On the frame bottom plate 6; when the drive motor 2 drives the mixing tank 3 to move up and down through the transmission crankshaft 10, the limit spring 9 expands and contracts with the mixing tank 3 up and down, and simultaneously limits the outward deflection of the mixing tank 3, The collision between the mixing blade 14 and the inner wall of the mixing tank 3 is avoided to improve safety.

[0033] The working principle of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com