Intelligent biomass waste rapid fertilizer preparation fermentation machine

A biomass waste and fermenter technology, which is applied to the treatment of biological organic parts, organic fertilizers, fertilization devices, etc., can solve the problems of slow fermentation efficiency of fermenters, incomplete extraction of liquid fertilizer, and poor sealing, and achieve complete extraction. , high degree of sealing, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

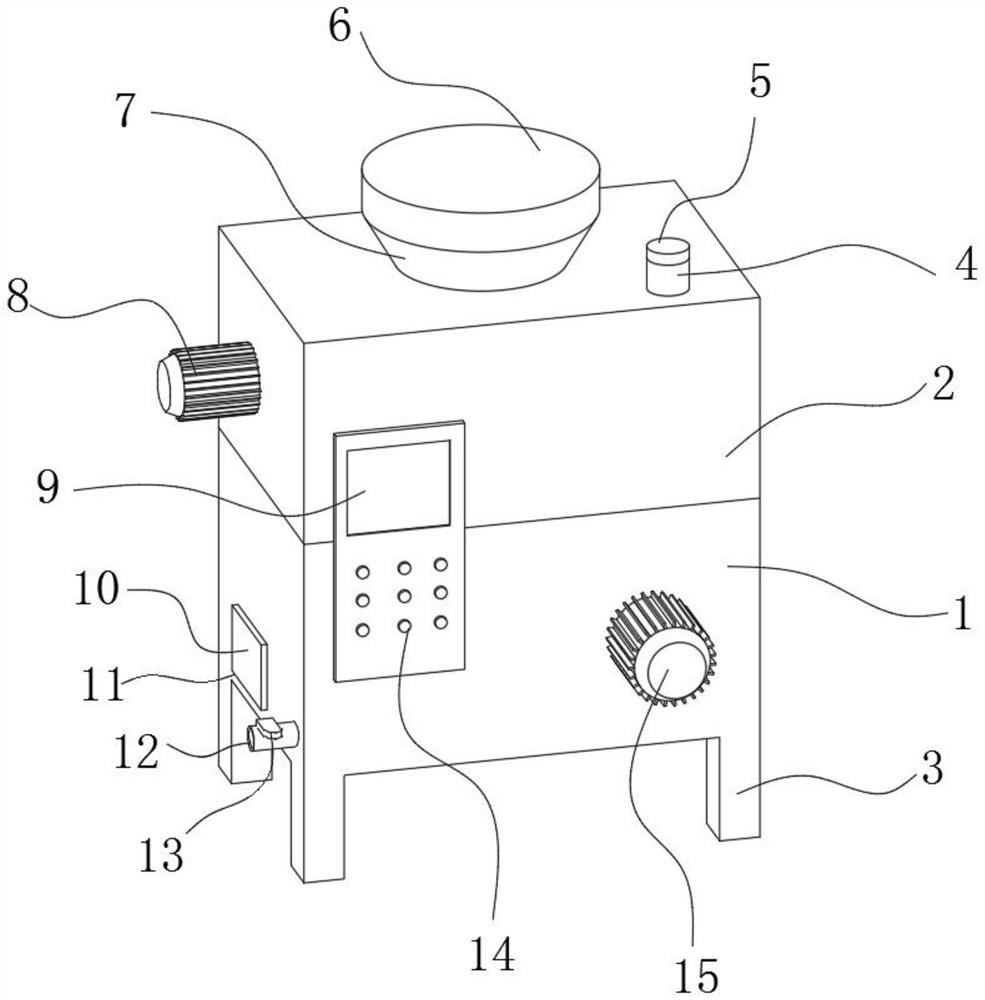

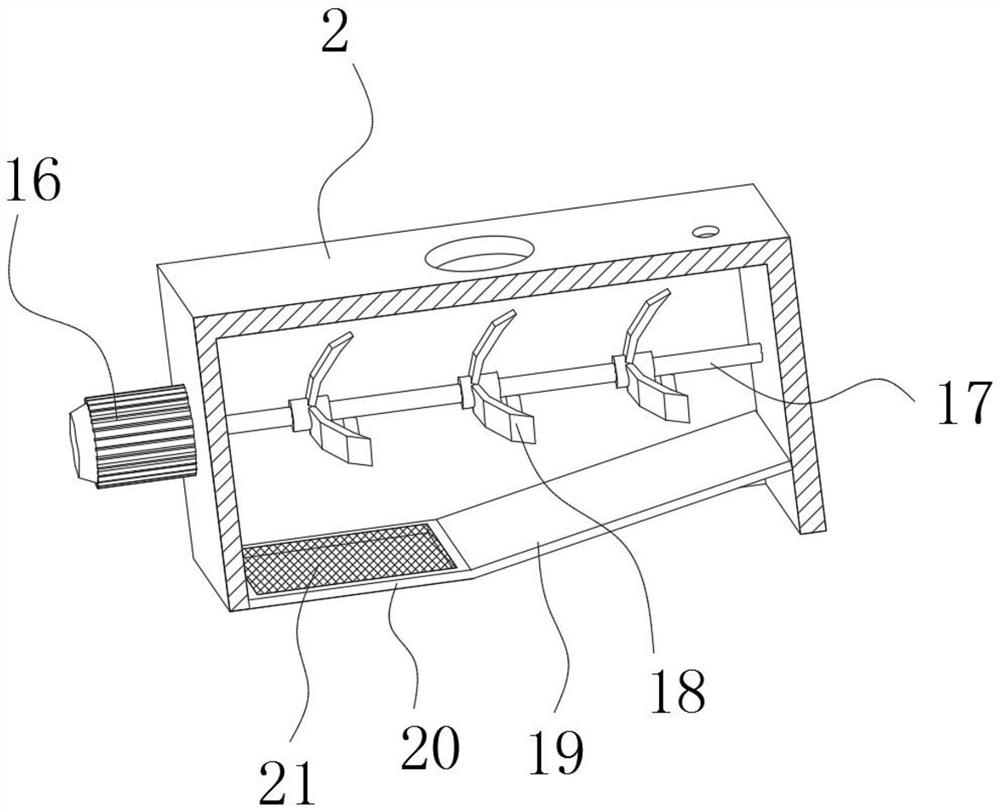

[0030] An intelligent biomass waste fast fertilizer fermentation machine, such as Figure 1-2As shown, the fermentation box 1 is included, the upper end of the fermentation box 1 is fixedly connected with a crushing box 2, the four corners of the lower end of the fermentation box 1 are fixedly connected with support legs 3, and the middle part of the upper end of the crushing box 2 is fixedly connected with a feed port 7, and the feeding The upper end of the mouth 7 is provided with a No. 2 electromagnetic sealing cover 6, the upper right part of the upper end of the crushing box 2 is fixedly connected with a catalyst inlet 4, and the upper end of the catalyst inlet 4 is provided with a No. 1 electromagnetic sealing cover 5, and the catalyst inlet 4 and the feeding port 7 are connected to the The inside of the crushing box 2 is connected, the left end of the crushing box 2 is fixedly connected with a crushing device 8, and the right part of the crushing device 8 extends into th...

Embodiment 2

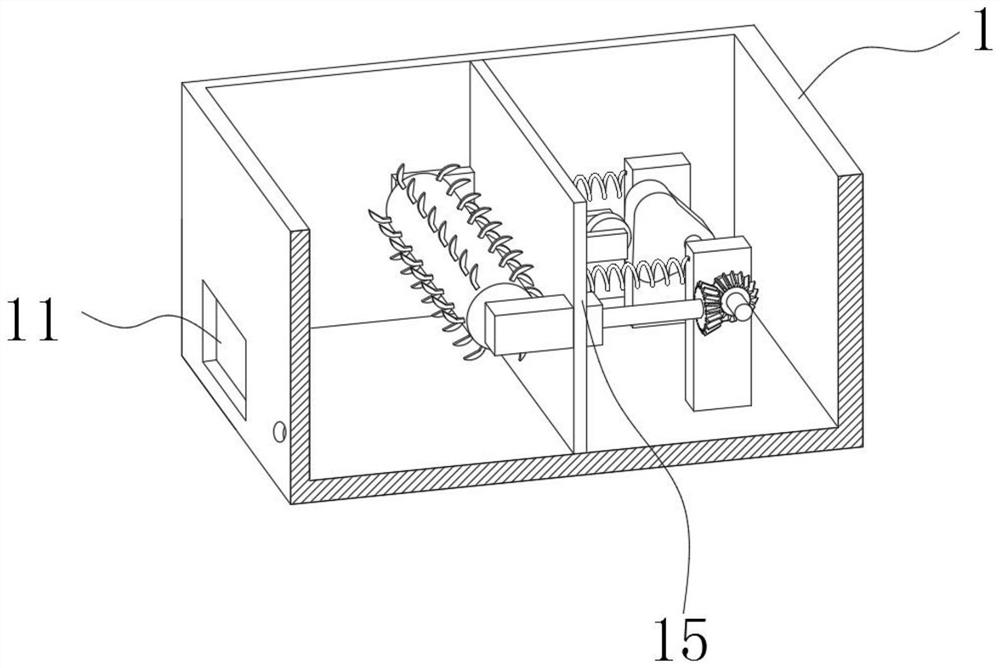

[0033] On the basis of Example 1, as Figure 3-7 As shown, a fermenter for rapid fertilization of intelligent biomass waste comprises a fermentation box 1, the upper end of the fermentation box 1 is fixedly connected with a crushing box 2, and the four corners of the lower end of the fermentation box 1 are fixedly connected with supporting legs 3, and the breaking box 2 The upper middle part of the upper end is fixedly connected with the material inlet 7, and the upper end of the material inlet 7 is provided with a No. The cover 5, the catalyst inlet 4 and the feed port 7 are all connected to the interior of the crushing box 2. The left end of the crushing box 2 is fixedly connected with a crushing device 8, and the right part of the crushing device 8 extends into the crushing box 2. The fermentation box 1 and the crushing box 2 are connected to each other. The front left part of the case 2 is fixedly installed with a control panel 9, the lower front end of the control panel 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com