Alkali metal steam laser of polarized optical pumping

An alkali metal vapor pool and alkali metal technology, applied in lasers, laser components, phonon exciters, etc., can solve the problems of low efficiency, high cost, low laser output power, etc., and achieve high repetition rate and high power output , the effect of increasing the absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

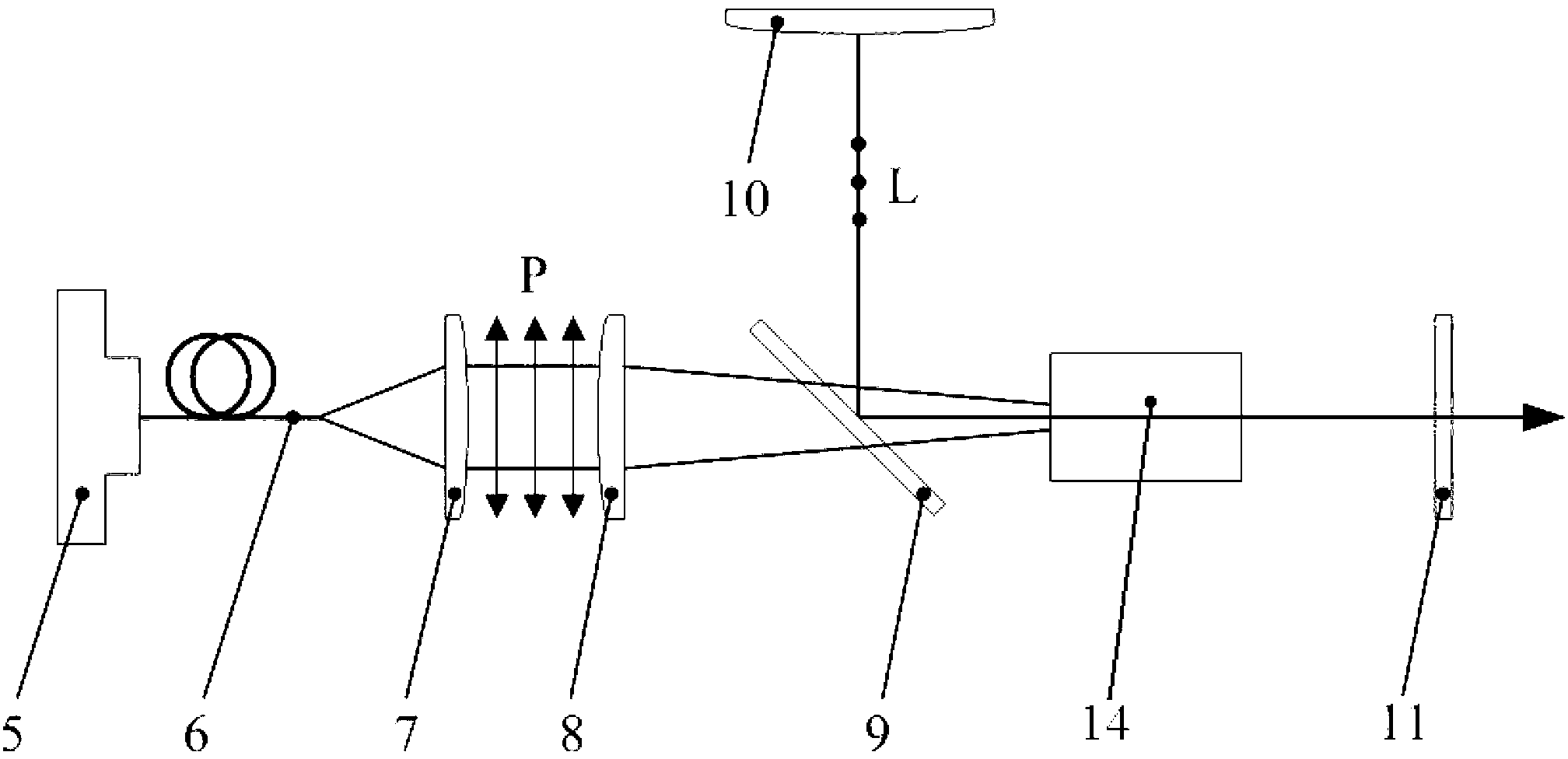

[0033] Specific implementation mode one, such as image 3 As shown, a polarized light-pumped alkali metal vapor laser of the present invention includes: an LD pumping unit for emitting and coupling pump light, a gain unit 14 for realizing laser amplification and a laser for realizing laser amplification. For an oscillating resonant cavity, the LD pump unit is placed outside the resonant cavity, and the gain unit 14 is placed inside the resonant cavity.

[0034] The LD pump unit in this embodiment is composed of an LD pump source 5 emitting pump light, a transmission fiber 6 transmitting the pump light, and a coupling lens group for coupling and focusing the pump light. The light is linearly polarized light in the p direction, and the polarization direction is orthogonal to the polarization direction of the oscillating light; the pump light is output to the coupling lens group through the transmission fiber 6, the core diameter of the transmission fiber 6 is 400 μm, and the num...

specific Embodiment approach 2

[0042] Specific implementation mode two, such as Figure 4 As shown, on the basis of the laser described in Embodiment 1, an acousto-optic Q switch 12 is inserted in the resonant cavity to achieve a high repetition rate output of laser light, and the acousto-optic Q switch 12 is placed between the gain unit 14 and the output mirror 11 , the acousto-optic Q switch 12 is placed in the plano-convex unstable cavity according to the Bragg diffraction conditions. The intracavity loss is serious, and laser oscillation cannot be formed; if the ultrasonic wave is suddenly removed, the intracavity loss suddenly drops, thereby forming a laser pulse. Driven by a high-frequency oscillation power supply, the above process is repeated to form a high repetition rate output of laser pulses.

[0043] The positions and functions of the LD pump unit, the gain unit 14 and the resonance cavity in this embodiment are the same as those described in the first embodiment.

[0044] In this embodiment, ...

specific Embodiment approach 3

[0048] Specific implementation mode three, such as Figure 5 As shown, on the basis of the laser described in Embodiment 1, in order to increase the output power of the laser, the method of double-terminal pumping of the LD double-alkali metal vapor cell is adopted, and the gain volume is increased and the pumping power of the LD injection is increased. Increase the output power of the alkali metal vapor laser.

[0049] In this embodiment, another gain unit 14 and a group of LD pumping units are placed between the gain unit 14 and the output mirror 11. The newly added group of LD pump units is placed close to the output mirror 11. The newly added gain unit 14 Unit 14 is placed close to another gain unit 14, and another polarizer 9 is also placed between the newly added group of LD pump units and a newly added gain unit 14, and the two-way pumps from two groups of LD pump units The pump light enters the adjacent alkali metal vapor pool 4 respectively, and pumps the alkali meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com