A wafer etching back grinder

A back-grinding and grinding machine technology, applied in grinding machine tools, grinding devices, manufacturing tools, etc., can solve the problems of wafer precision decline and impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

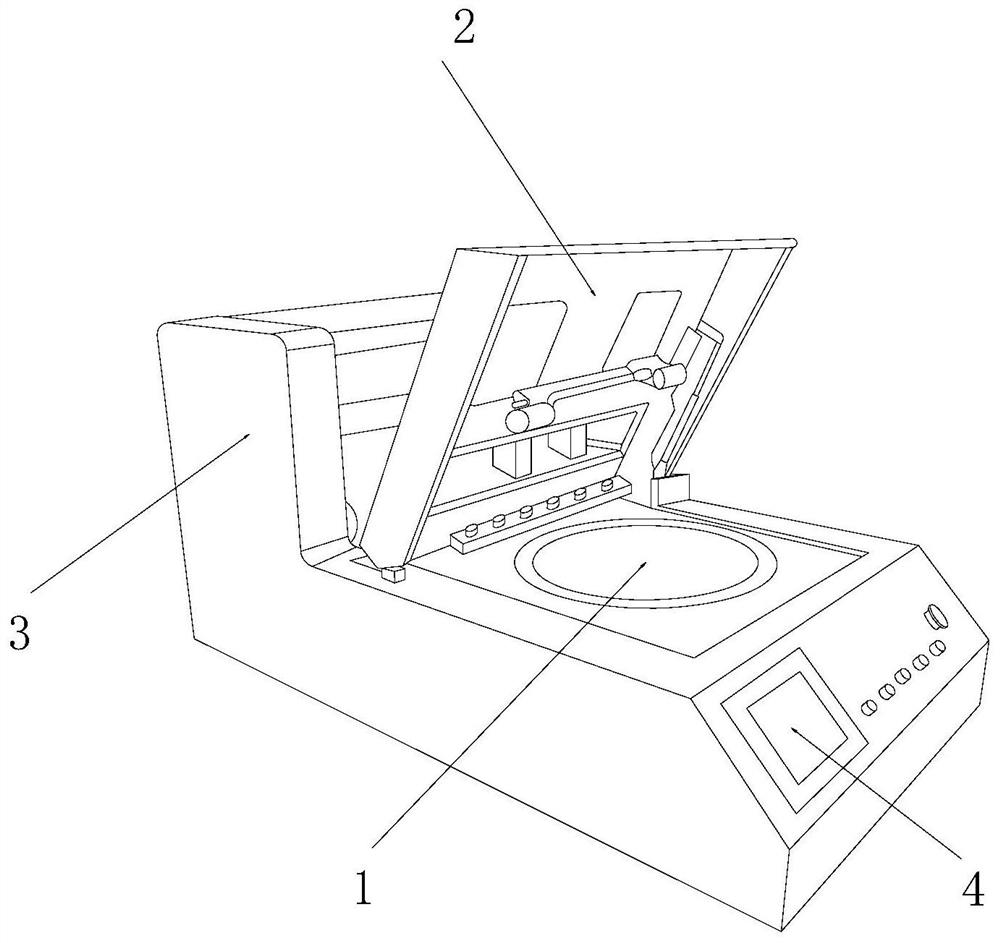

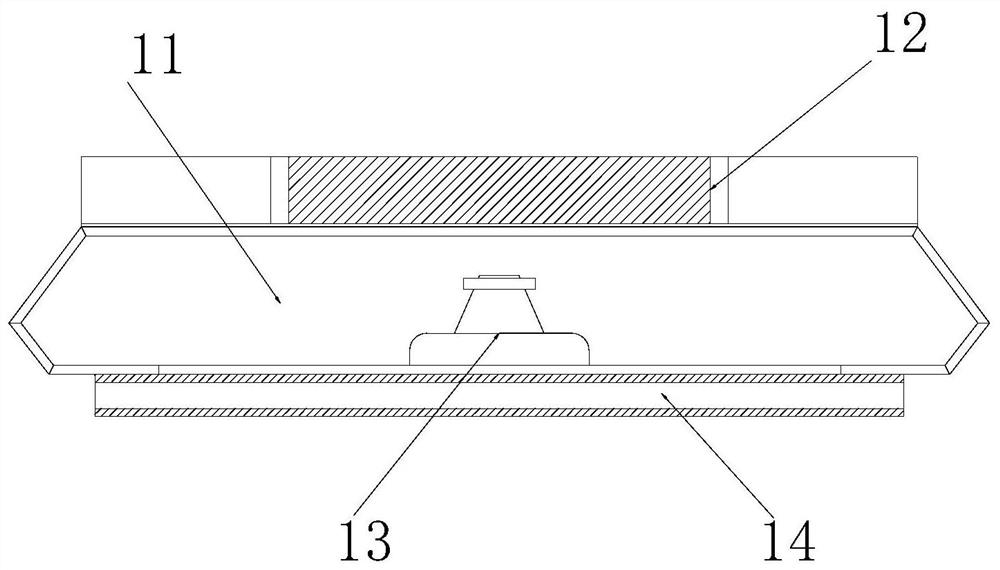

[0025] as attached figure 1 to attach Figure 5 Shown:

[0026] The present invention provides a wafer etching backside grinding machine, the structure of which includes a grinding mechanism 1, a cover plate 2, an equipment base 3, and a control panel 4. The grinding mechanism 1 is embedded and installed on the right upper end surface of the equipment base 3. The cover plate 2 is engaged and connected with the equipment seat 3, and the control panel 4 is fixedly mounted on the right end surface of the equipment seat 3; the grinding mechanism 1 includes a vacuum tank 11, an installation mechanism 12, a grinder 13, a sliding Rail 14, the vacuum tank 11 is inlaid directly above the slide rail 14, the installation mechanism 12 is inlaid and mounted directly above the grinder 13, and the grinder 13 is movably mounted on the slide rail 14 Above, the slide rail 14 is installed directly below the grinder 13 by welding.

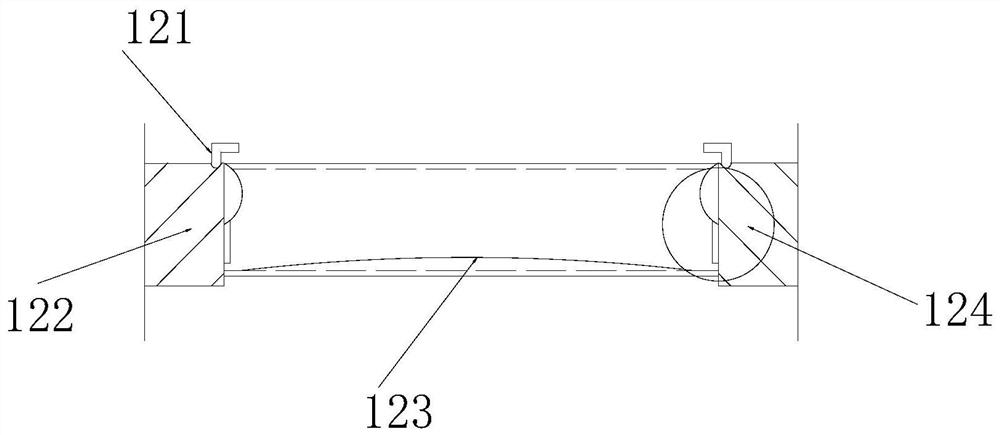

[0027] Wherein, the installation mechanism 12 includes a lock...

Embodiment 2

[0033] as attached Figure 6 to attach Figure 7As shown: the grinder 13 includes a heat insulation mechanism 131, a radiation port 132, a heat conduction block 133, a limiting plate 134, and an extension tube 135. The heat insulation mechanism 131 is embedded and installed directly above the radiation port 132, and the radiation The lateral outer end surface of the mouth 132 is inlaid and connected with the heat conduction block 133, and the heat conduction block 133 is symmetrically installed on the left and right sides of the upper end of the limit plate 134, and the limit plate 134 is embedded and installed directly above the extension tube 135, so that The extension tube 135 is nested and installed on the inner end surface of the grinder 13, and the connection end surface of the heat insulation mechanism 131 and the radiation port 132 is provided with an embedded tube. By limiting the area of laser temperature diffraction, the grinding problem can be effectively solved....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com