Equipment for improving preheating efficiency of cylinder body before welding

A pre-welding preheating and efficiency technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of affecting welding quality, affecting cylinder preheating effect and preheating efficiency, uneven preheating, etc. problem, to achieve the effect of improving quality, improving preheating effect and preheating efficiency, and reducing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

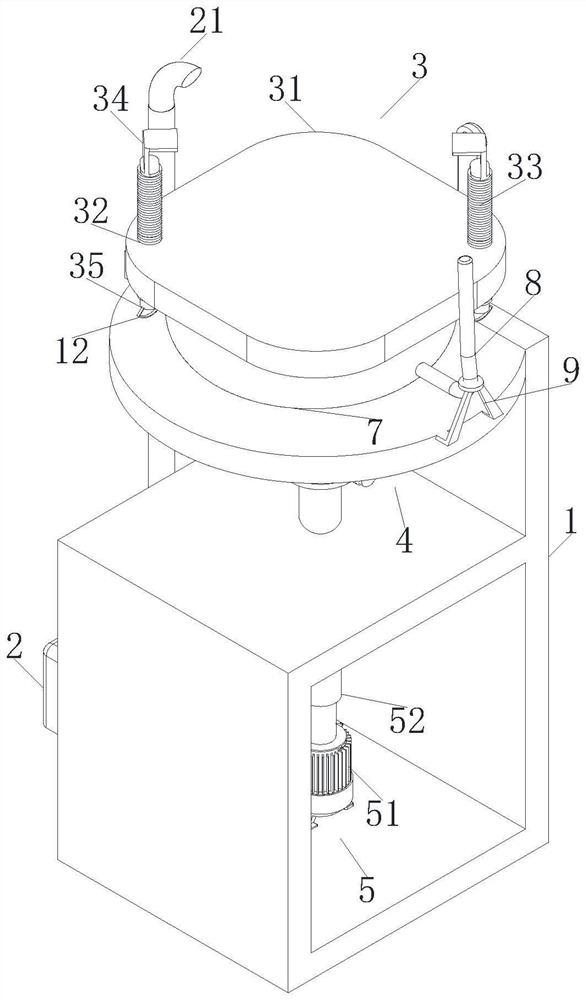

[0059] As a specific embodiment of the present invention, the rotating mechanism 5 includes:

[0060] Motor 51; the motor 51 is fixed in the body 1; used to provide power;

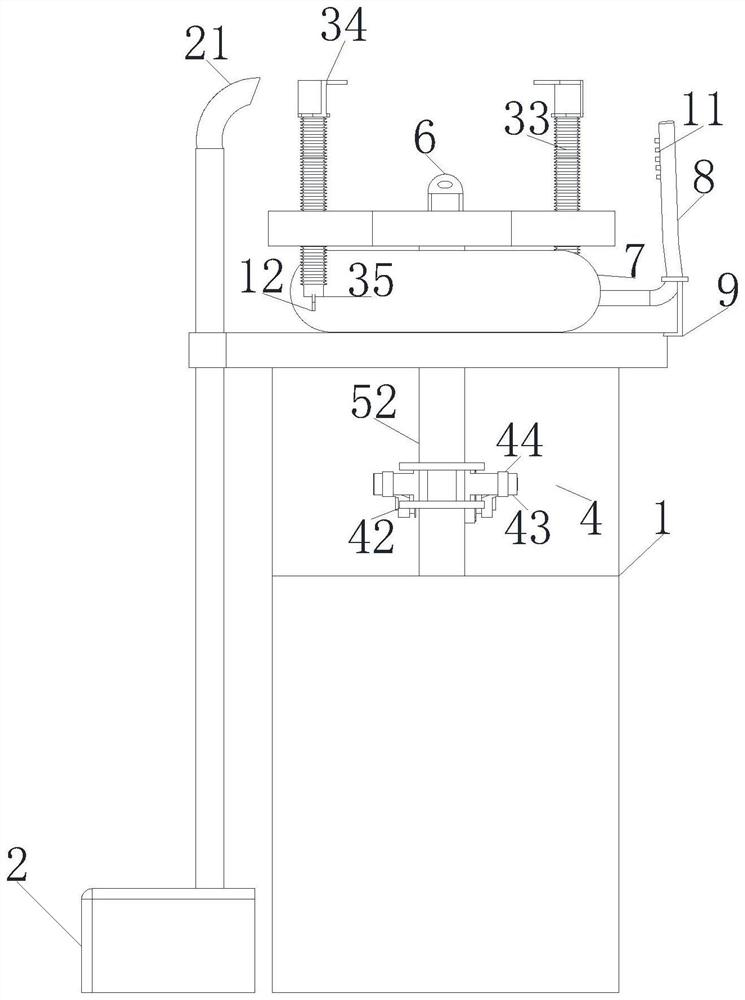

[0061] Telescopic rod 52; one end of the telescopic rod 52 is affixed to the rotating shaft of the motor 51; the end of the telescopic rod 52 away from the motor 51 runs through the body 1 and is rotationally connected with the body 1, and the telescopic rod 52 is far away from the output shaft of the motor 51 One end of one end is fixedly connected with the placement table 31;

[0062] When performing preheating treatment on different welding surfaces, the staff starts the motor 51. After the motor 51 is started, it drives the telescopic rod 52 fixed on the rotating shaft of the motor 51 to rotate. The cylinder on the platform 31 rotates to preheat the different welding surfaces of the cylinder, which improves the heating area of the cylinder by the baking gun 21, avoids the uneven preheating of the cy...

Embodiment approach

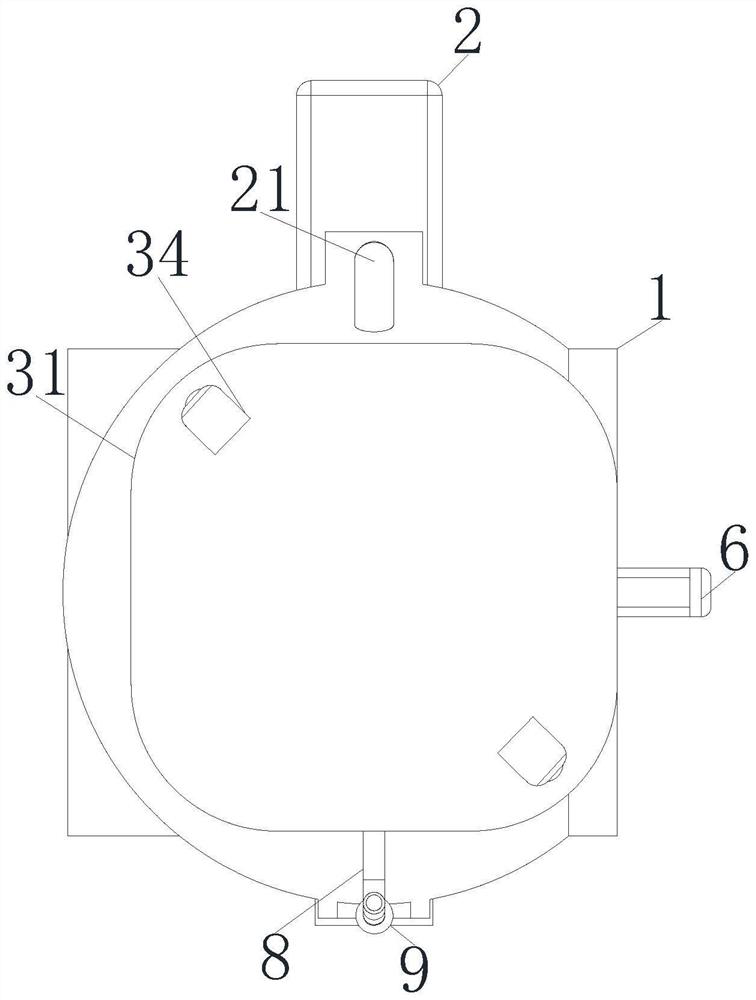

[0073] As a specific embodiment of the present invention, the body 1 is provided with a bracket 9 on the side close to the air duct 8, one end of the bracket 9 is fixedly connected to the body 1, and the other end is sleeved on the air duct 8;

[0074] The bracket 9 is fixed on one side of the body 1. When the placing table 31 squeezes and expands the airbag fixed on the body 1, it may cause unnecessary deviation of the airway 8 suspended on the side of the airbag, affecting the airway. 8 to clean the surface of the cylinder body, so a bracket 9 is fixedly connected to one side of the body 1, providing an additional support point for the air guide tube 8, improving the practicability of the air guide tube 8 for cleaning the surface of the cylinder body, and avoiding extrusion The deflection of the air guide tube 8 during the process of the air bag ensures that the air guide tube 8 cleans the entire cylinder surface.

[0075] As a specific embodiment of the present invention, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com