Spiral protective belt machining method

A processing method and protection tape technology, applied in metal processing and other directions, can solve problems such as thermal deformation of the spiral protection tape, and achieve the effect of solving thermal deformation and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

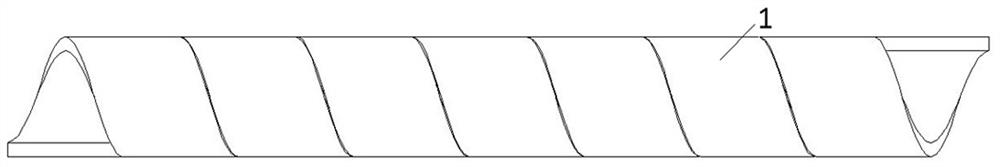

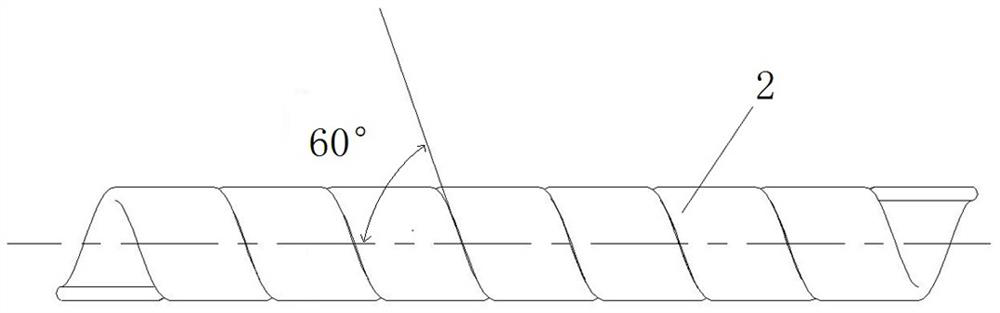

[0024] The specific embodiment of the processing method of spiral protective band of the present invention, as image 3 and Figure 4 As shown, the pipe fitting blank used in the present invention for processing the spiral protection band 2 is a plastic hard pipe, and the lathe used is a common horizontal lathe, such as Figure 5 to Figure 8 As shown, the cutting tool 3 during processing includes two C-shaped cutter bodies 30. In this embodiment, the two C-shaped cutter bodies 30 have an integrated structure. The side of 31 is provided with a chip removal groove 32 between two C-shaped cutter bodies, and the main cutting edge 31 is an arc-shaped cutting edge. Through the relative circular rotation of the cutting tool 3 and the processing pipe blank, cutting water pipes and cutting edges are simultaneously realized. The purpose of edge chamfering.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com