Intelligent rice noodle packaging equipment

A smart packaging and rice noodle technology, applied in packaging, transportation packaging, packaging protection, etc., can solve the problems of unsteady supervision, truncated structure still running, low production efficiency, etc., to achieve flexible and convenient use, avoid waste of resources, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

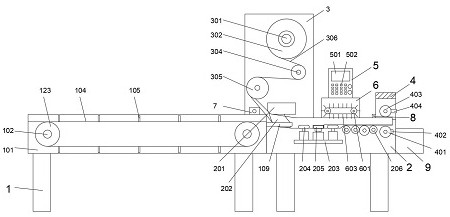

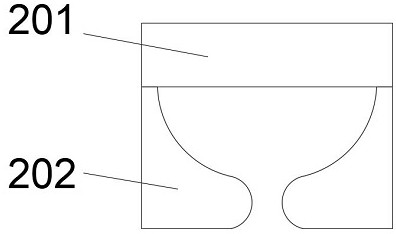

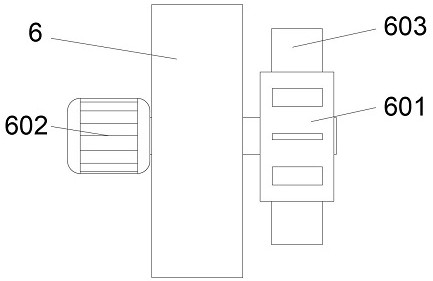

[0035] Such as Figure 1-8 As shown, the embodiment of the present invention provides a kind of intelligent packaging equipment for rice noodles, including a first conveying device 1, a second conveying device 2 arranged at one end of the first conveying device 1, a The packaging conveying device 3 in the middle position, the cutting device 4 located at one end of the second conveying device 2, the control device 5, and the auxiliary device 6, the first conveying device 1 includes a conveying frame 101, and both ends of the conveying frame 101 are provided with a second One rotating shaft 102, the first two first rotating shafts 102 are provided with the first conveying wheel 103, the two first conveying wheels 103 are connected with the conveyer belt 104, the conveying frame 101 side is provided with the first motor 106, the first motor The driving end of 106 and one end of one of the first rotating shafts 102 are both provided with a pulley 107 , and the two pulleys 107 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com