Laser direct light control device for coating machine

A laser direct coating machine technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problems of measurement error accumulation and monitoring accuracy reduction, so as to reduce accumulation tolerance and improve measurement accuracy degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

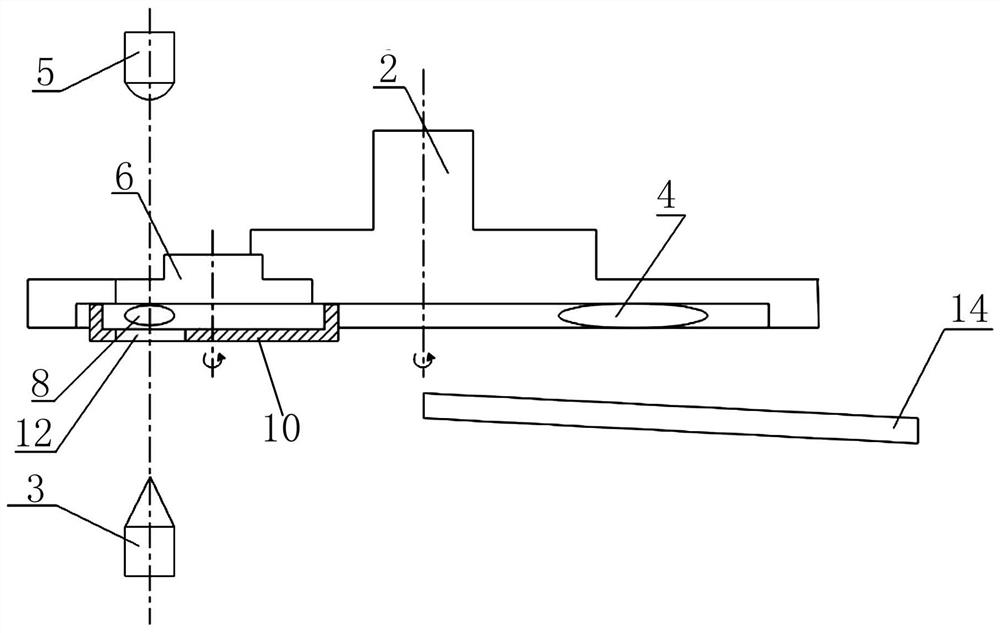

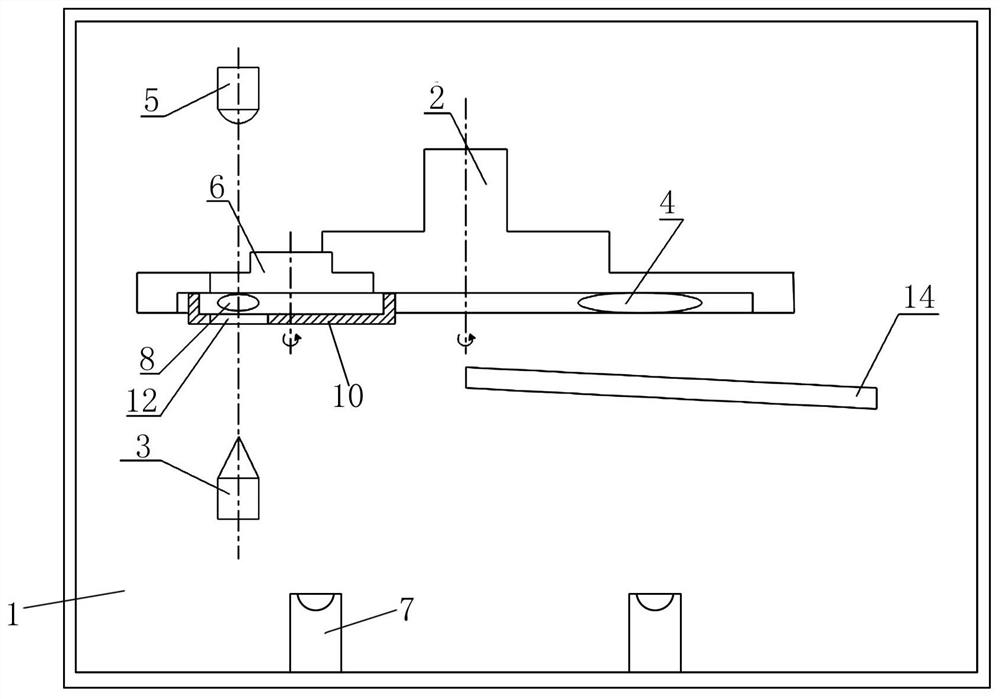

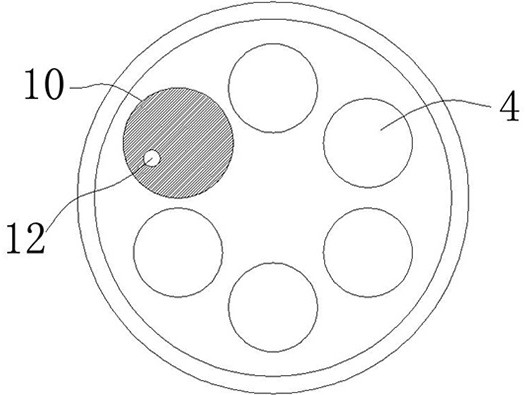

[0026] The evaporation coating is completed in the coating chamber. The evaporation coating process is composed of materials with different refractive indices deposited onto the substrate layer by layer. The embodiment of the present invention discloses a laser direct light control device for a coating machine, which is used for evaporation coating. The coating thickness is monitored in real time during the process. Among them, during the evaporation coating process, the light transmittance fluctuates with the increase of the coating thickness, and when it reaches the extreme value (maximum value / minimum value), the optical thickness of the coating film (the product of the actual thickness and the refractive index of the coating film) is 4 points When the light transmittance completes a change between extreme values, it can be seen that the optical thickness of the coating increases by a quarter of the wavelength, so the thickness of the coating can be calculated by monitoring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com