Heat dissipation device for automobile engine

A technology of automobile engine and heat dissipation device, which is applied in the direction of engine components, machine/engine, engine cooling, etc., can solve the problems of single heat dissipation structure and function of engine radiator, difficulty in releasing high-temperature air of engine, and affecting normal operation of engine, etc., to achieve Improve the effect of heat dissipation and cooling, accelerate air exchange, and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

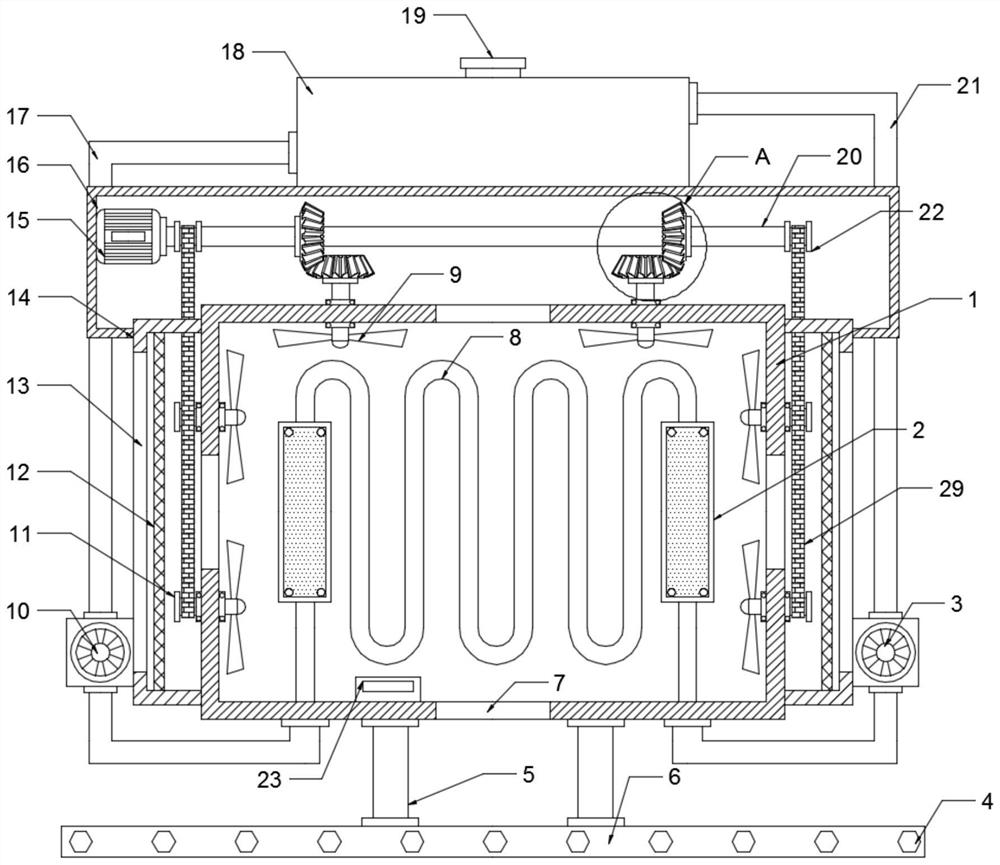

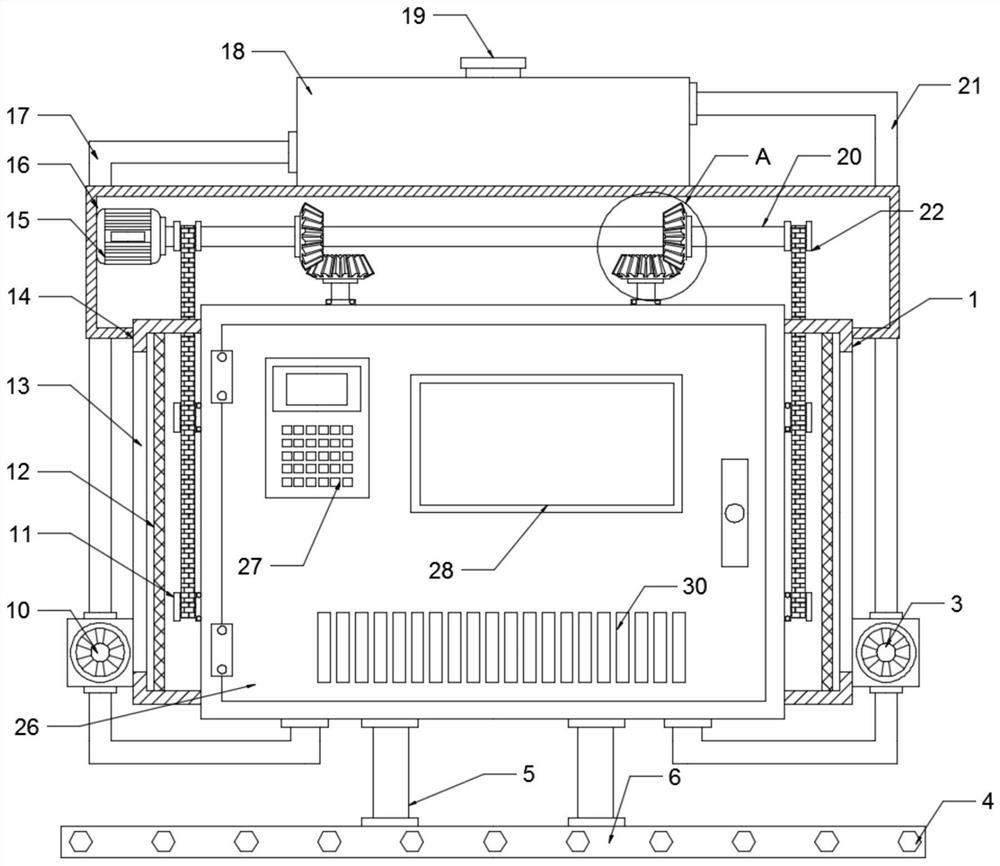

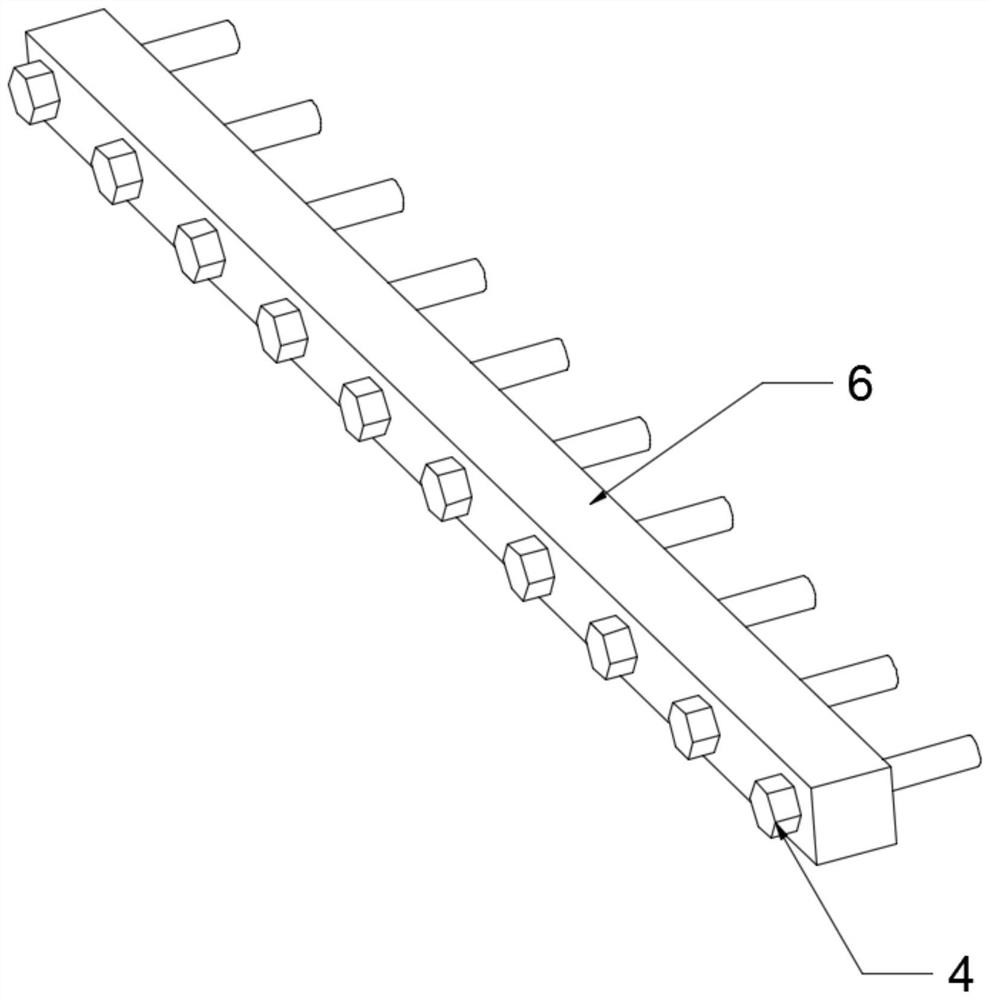

[0022] see Figure 1-4 , a heat dissipation device for an automobile engine, comprising a heat dissipation box 1 and a mounting base 6, an engine body is installed in the heat dissipation box 1, a heat dissipation port 7 is arranged in the middle of the side wall of the heat dissipation box 1, and the top wall of the heat dissipation box 1 A drive motor 15 is set, the output end of the drive motor 15 is fixedly connected to the rotating shaft 20, the left and right sides of the surface of the rotating shaft 20 are symmetrically provided with bevel gears 1-24, and the left and right sides of the inner top wall of the heat dissipation box 1 are symmetrically provided with fans 9. The fan 9 is rotatably connected with the top wall of the heat dissipation box 1, and the top of the fan 9 passes through the top wall of the heat dissipation box 1 through a connecting rod and extends and is fixedly connected to the second bevel gear 25. The second bevel gear 25 meshes with the bevel ge...

Embodiment 2

[0028] see Figure 1-2 , on the basis of Embodiment 1, in order to cool down the heat dissipation box 1, a water tank 18 is arranged above the heat dissipation box 1, and a water pump 10 is arranged on the left side of the heat dissipation box 1, and the water pump 10 and the water tank 18 pass through the water inlet pipe 17 connection, the serpentine cooling pipe 8 is set in the heat dissipation box 1, the water inlet pipe 17 extends through the left side wall of the heat dissipation box 1 and connects the serpentine cooling pipe 8, and the water pump 10 transfers the water in the water tank 18 through the water inlet pipe 17 The water is sent to the serpentine cooling pipe 8, and the serpentine cooling pipe 8 cools the inside of the heat dissipation tank 1. In order to repeatedly recycle the water in the water tank 18, a circulation pump 3 is arranged under the right side wall of the heat dissipation tank 1 The end of the serpentine cooling pipe 8 away from the water inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com