Bearing running-in machine

A technology of bearings and spindles, which is applied in the direction of mechanical bearing testing, mechanical equipment, springs/shock absorbers, etc., can solve the problems that bearings of different sizes cannot be replaced, buffering and shock absorption cannot be provided, and bearing replacement is inconvenient, so as to improve quality, Solve the effect of inconvenient replacement of bearings and convenient replacement and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

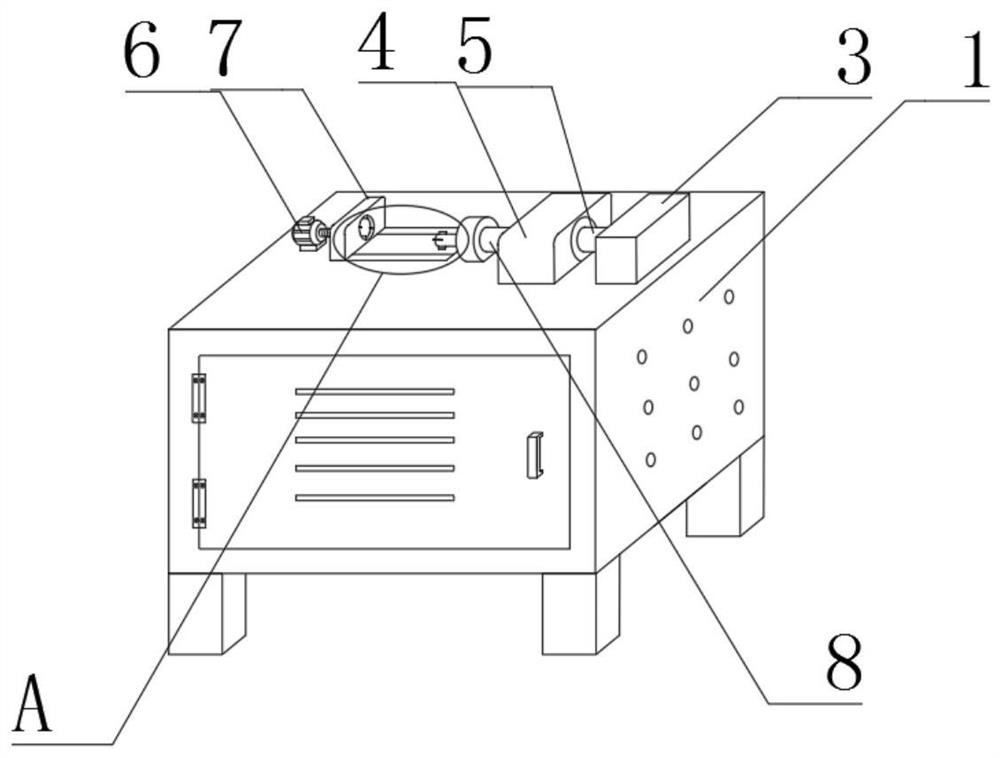

[0024] like figure 1 , 2 As shown, a bearing running-in machine includes a device main body 1, a gearbox 3 is arranged on the top surface of the device main body 1 near the right edge, a headstock 4 is arranged on the upper surface of the device main body 1 near the gearbox 3, and the main shaft A shaft coupling 5 is arranged between the case 4 and the gearbox 3, a main shaft 8 is arranged on the left side of the headstock 4, a rotating shaft 11 is arranged at the port of the main shaft 8, and a motor is arranged on the upper surface of the main body 1 near the left edge. 6. A fixed baffle 7 is arranged on the right side of the motor 6, and a threaded rod 16 is arranged between the fixed baffle 7 and the motor 6. The motor 6 drives the threaded rod 16 to rotate, and the fixed baffle 7 is moved and fixed by thread force.

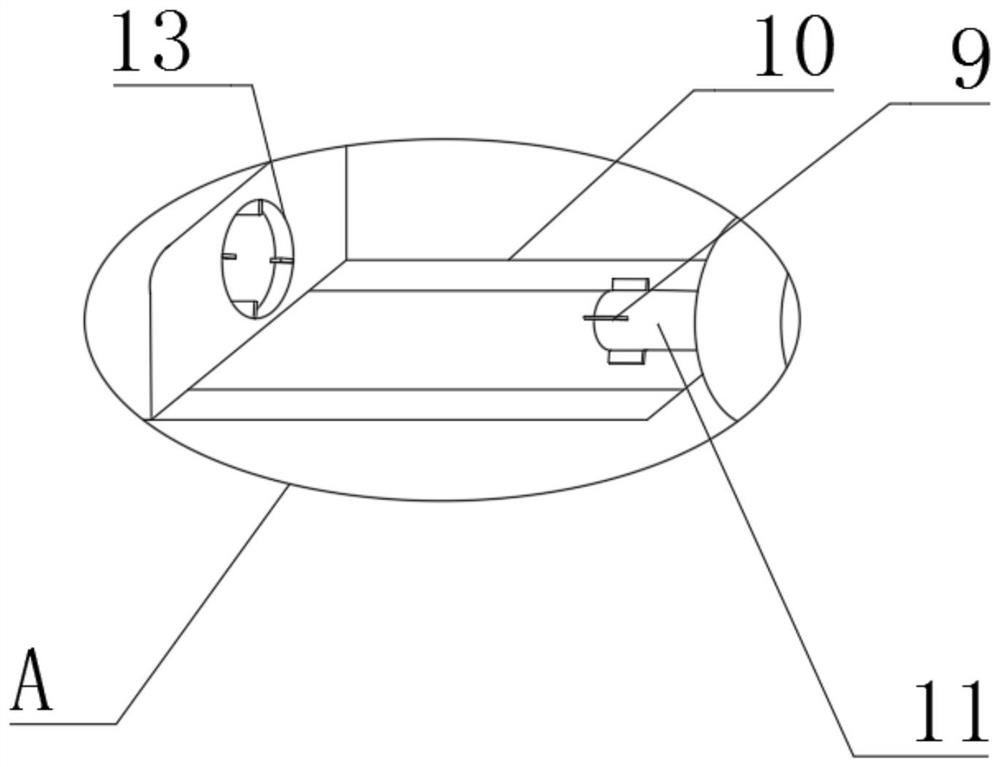

[0025] A slide rail 10 is provided between the bottom of the fixed baffle 7 and the top surface of the main body 1 of the device. The slide rail 10 extends ...

Embodiment 2

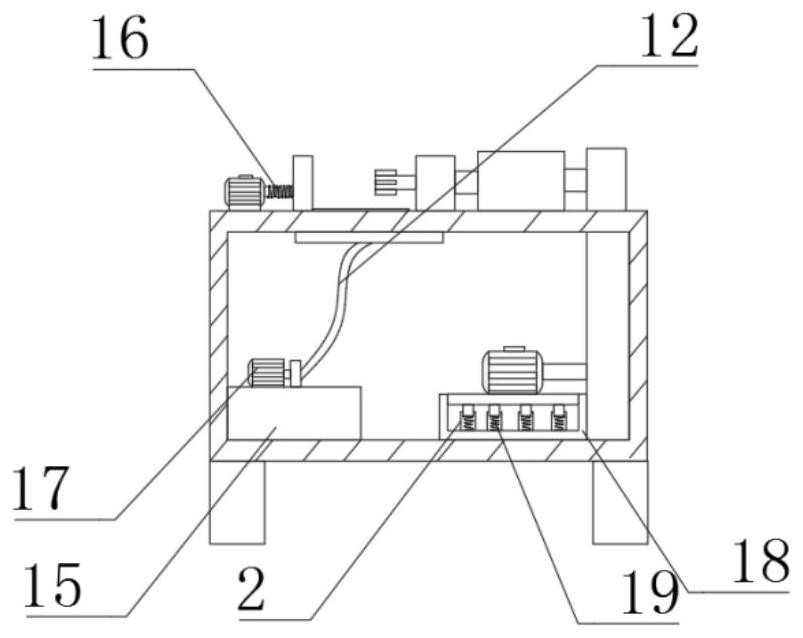

[0028] On the basis of Embodiment 1, such as image 3 , 4 As shown, the gearbox 3 runs through the top of the device main body 1 and is connected to the inner bottom surface of the device main body 1, and the inner bottom surface of the device main body 1 is provided with a shock absorbing plate 18 near the gearbox 3, and the inner bottom surface of the shock absorbing plate 18 is provided with a movable Groove 2, the interior of movable groove 2 is provided with damping spring 19, reduces the vibration of running-in machine, reduces noise and provides stable running-in environment, improves running-in quality.

[0029] The damping plate 18 and the device main body 1 are flexibly connected, the movable groove 2 and the damping plate 18 are fixedly connected, the damping spring 19 and the movable groove 2 are flexibly connected, and the number of movable grooves 2 is four groups. , the movable slots 2 are arranged in an array, and the number of shock absorbing springs 19 is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com