Engine test pre-centering method

A technology for engines and small and medium vehicles, which is applied in the direction of engine testing, machine/structural component testing, and measuring devices. It can solve the problems of small space in the test room and difficult operation, and achieve convenient use, easy installation, accurate positioning, and improved testing. The effect of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

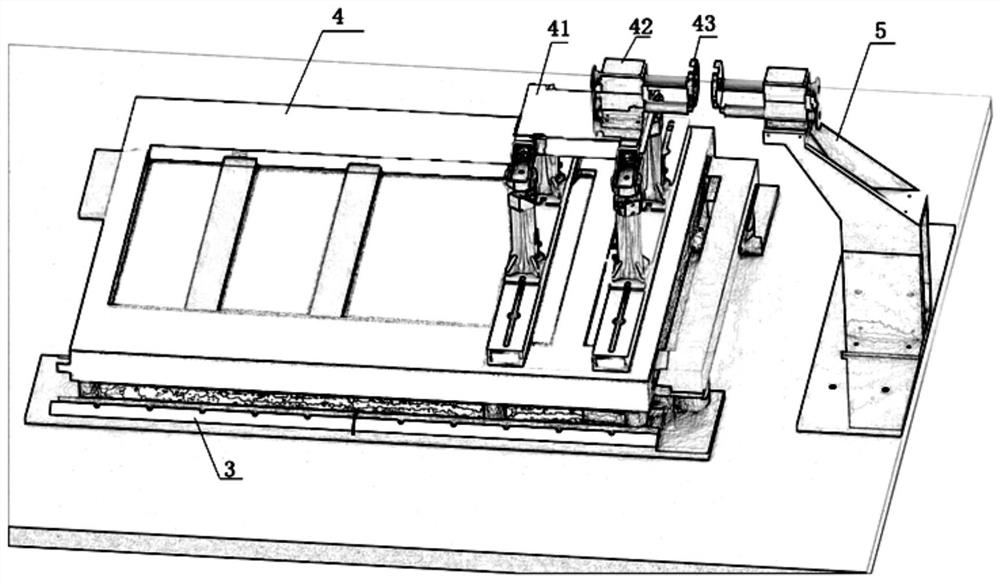

[0032] Such as Figure 1-4 Shown, a kind of engine test pre-centering method of the present invention comprises the following steps:

[0033] 1) Install the reference plate on the ground: choose an open ground outside the laboratory to drill holes, use large-size expansion bolts to fix and level the iron plate, and the iron plate after leveling can be used as the reference plate;

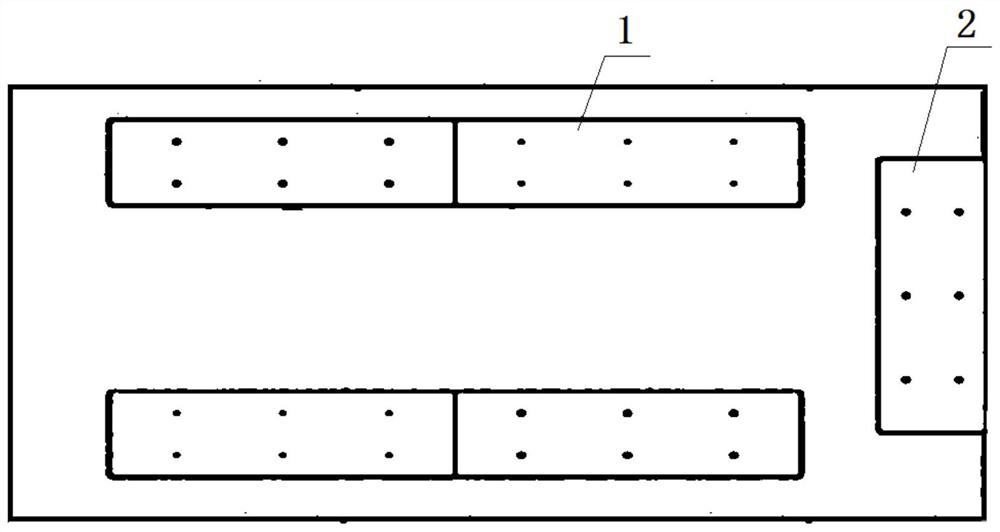

[0034] 2) Install the trolley positioning block and guide rail on the reference plate 3: Install the same trolley positioning block as the bench positioning block in the original laboratory on the reference plate to ensure that it is consistent with the positioning method of the bench in the original laboratory;

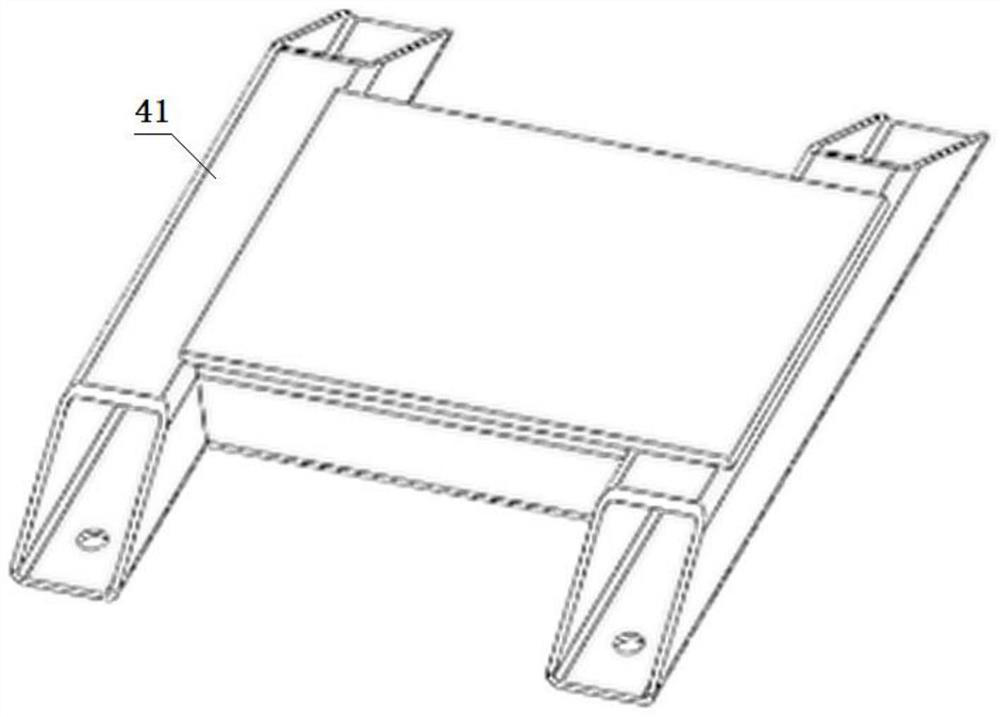

[0035] 3) Assemble the simulated centering trolley: install the simulated centering trolley 4 on the guide rail 3 of the reference plate according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com