Automatic product process tracing equipment

A product, automatic technology, applied in office automation, instruments, manufacturing computing systems, etc., can solve problems such as inability to track product positioning, difficult to actively find, etc., to achieve convenient centralized analysis and processing, fast processing response speed, and operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

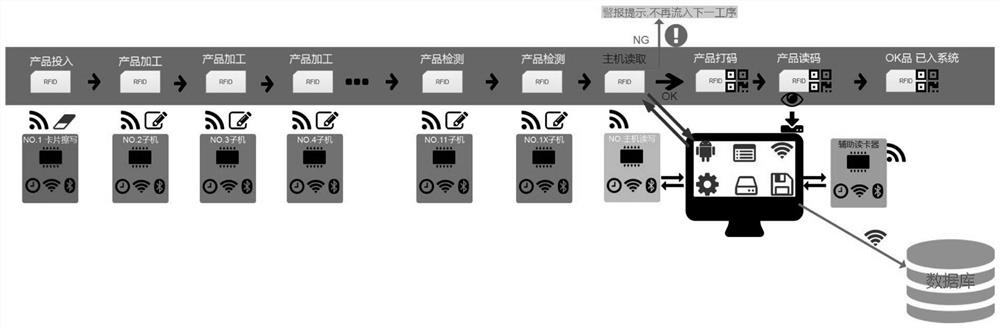

[0022] Such as figure 1 As shown, an automatic traceability device for a product process includes: a host computer (in order to make the expression clearer, in this embodiment, "host computer" is used instead of "host computer", such as figure 1 As shown), sub-machine, RFID card, the host computer and the sub-machine are provided with chips, that is, CPU, for data calculation and instruction sending and receiving, etc., which chip is specifically selected for the chip on the host computer and sub-machine, according to Actually need to choose and match by oneself; The host computer is connected with the sub-machine, and both the host computer and the sub-machine are equipped with RFID read-write modules, and the host computer and the sub-machine read and write the RFID card stored on the RFID card through the RFID read-write module. data, the RFID card is set on the product carrier on the production line. Preferably, the present invention also includes a database, and the data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com