Product production tracing management system and method

A management system and product technology, applied in general control systems, control/regulation systems, data processing applications, etc., can solve problems such as being difficult to be actively discovered, unable to locate and track products, and facilitate centralized analysis, processing, and processing. The effect of fast response and low technical threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

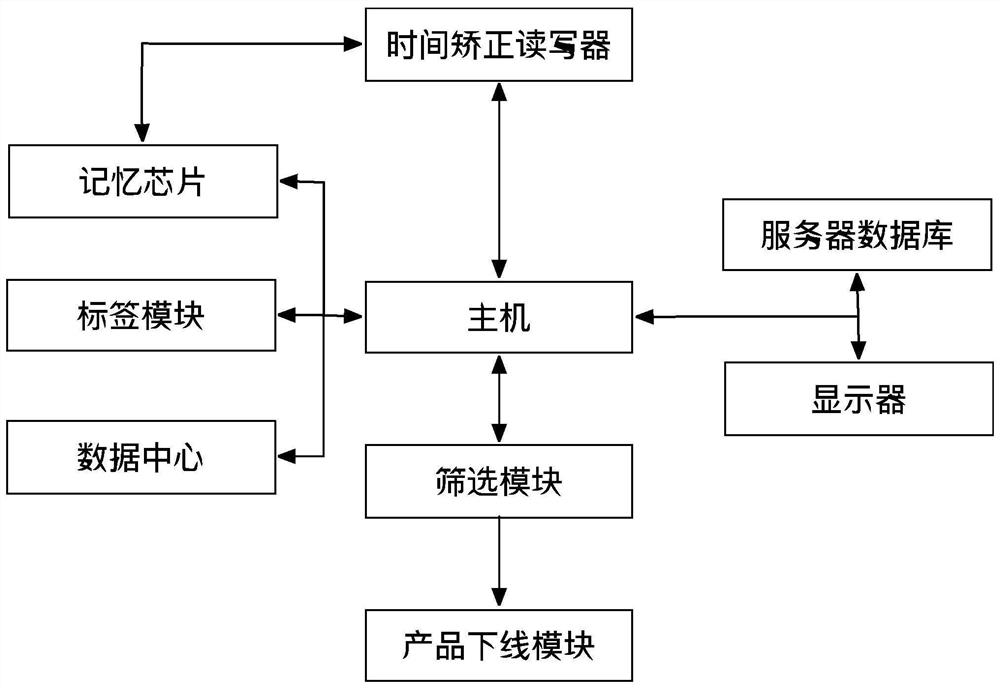

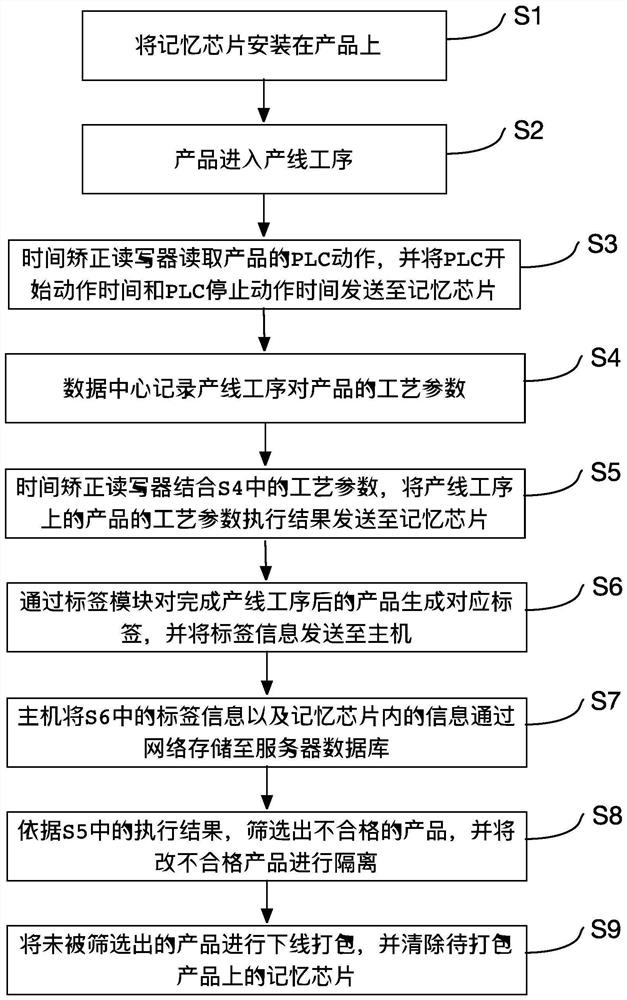

[0032] Such as figure 1 As shown, a traceability management system for product production, including: memory chip, time correction reader, data center, label module, host, server database, display, screening module, network connection module, product off-line module, said The memory chip is installed on the product to record the product on the production line corresponding to the production process; it should be noted that the start time and stop time of each station on the production line corresponding to the production process need to be recorded. Preferably, in the present invention, PLC is used to control the start time and stop time of each station.

[0033] The data center is used to record the process parameters of the product on the production line corresponding to the production process, and send the process parameters to the host; the time correction reader (as preferred, the time correction reader in the present invention A writer, preferably a reader-writer with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com