Wine bottle defect automatic detection method based on YOLOv3

An automatic detection and defect technology, which is applied in image data processing, image enhancement, instruments, etc., can solve the problems of large detection tasks, prone to missed detection, and large number of wine bottles, and achieves fast detection speed and convenient operation , Improving detection efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

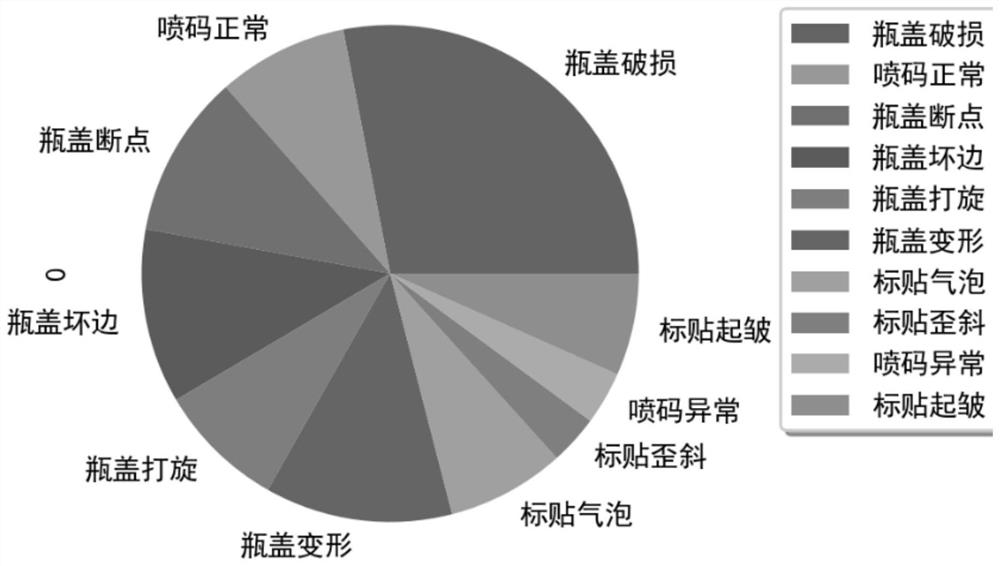

[0033] Such as Figure 1 to Figure 6 As shown, this embodiment discloses a wine bottle defect detection method based on deep learning target detection, which is characterized in that the one-stage YOLOv3 multi-scale feature extraction detection network is used to realize the accurate detection of multi-category and large-scale defect targets. Positioning and classification, specifically including the following implementation steps:

[0034] Step 1. Collect image data of abundant defective wine bottles on the production site for model learning.

[0035] (1) Since the bottle cap and bottle body may have flaws, pictures of the bottle body and bottle cap will be collected separately.

[0036] (2) Use a high-precision industrial camera to take pictures of defective wine bottles in the production environment. Cameras need to be arranged in two places, one for collecting bottle cap pictures, and the other for collecting bottle body pictures, such as figure 1 and figure 2 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com