Online measurement system for steam concentration of gas-phase mixture and method thereof

A steam concentration and measurement system technology, which is applied in the field of instrument measurement, can solve problems such as increasing the heat transfer resistance of condensation and affecting the heat transfer capacity of steam condensation, and achieve the effects of improving accuracy, easy deployment, and reducing mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

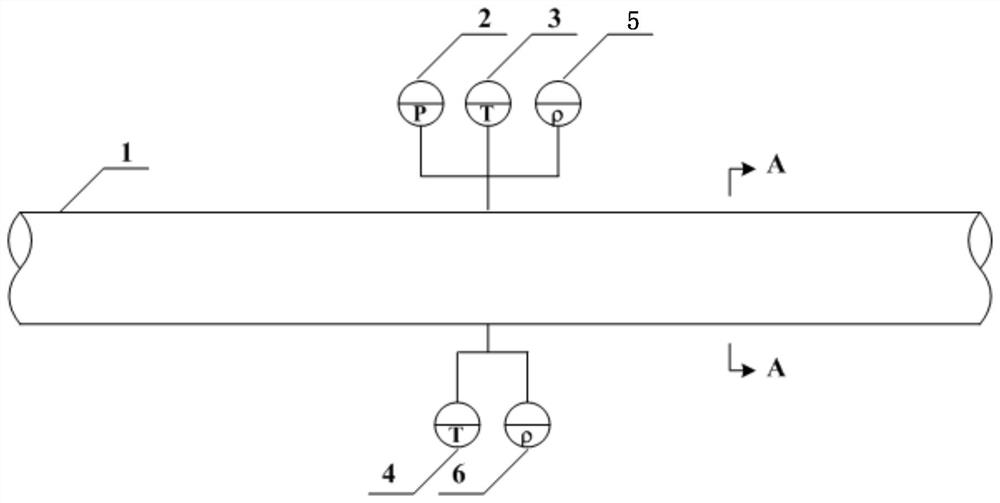

[0043] Such as figure 1 , figure 2 As shown, a vapor concentration online measurement system of a gas phase mixture includes a main gas pipe 1, a pressure sensor 2, a first temperature sensor 3, a second temperature sensor 4, a first density sensor 5 and a second density sensor 6;

[0044] The pressure sensor 2, the first temperature sensor 3, the second temperature sensor 4, the first density sensor 5 and the second density sensor 6 are installed on the side wall of the main air pipe 1; the pressure sensor 2, the first temperature sensor 3 , the second temperature sensor 4, the first density sensor 5 and the second density sensor 6 are arranged on the same axial plane of the main air pipe 1; the first density sensor 5 and the second density sensor 6 are tuning fork density meters.

[0045] The measurement method of the online measurement system described in this embodiment includes the following steps:

[0046] S1, through the pressure sensor 2, the first temperature senso...

Embodiment 2

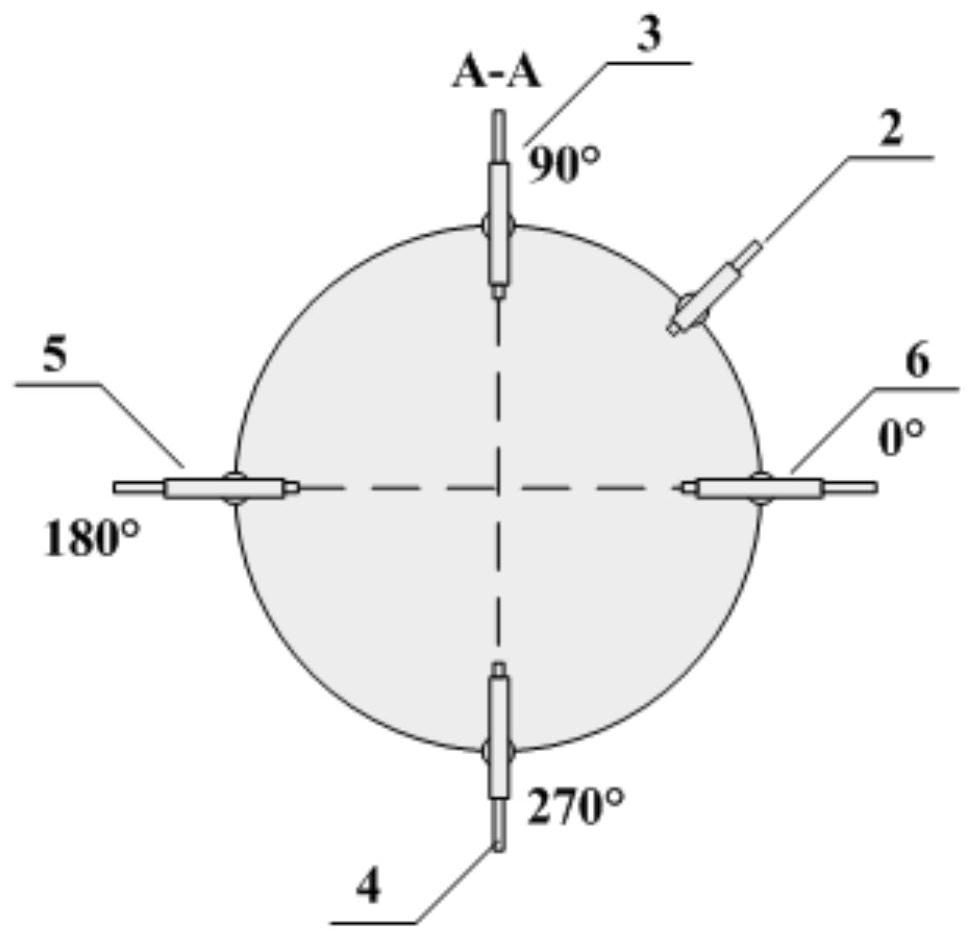

[0059] Such as figure 1 , figure 2 As shown, this embodiment is based on Embodiment 1, and the first temperature sensor 3 and the second temperature sensor 4 are arranged symmetrically with the central axis of the main air pipe 1; the first density sensor 5 and the second density sensor 6 are arranged with the main air pipe 1 The central axis of the trachea 1 is arranged symmetrically, specifically:

[0060] Take the horizontal point on the right side of the plane where the pressure sensor 2, the first temperature sensor 3, the second temperature sensor 4, the first density sensor 5 and the second density sensor 6 are located as 0°, and rotate counterclockwise; the pressure sensor 2 is located at 45° Orientation, the first density sensor 5 and the second density sensor 6 are located in the orientations of 0° and 180° respectively, and the first temperature sensor 3 and the second temperature sensor 4 are located in the orientations of 90° and 270° respectively.

Embodiment 3

[0062] Such as figure 1 , figure 2 As shown, this embodiment is based on Embodiment 1, the distance between the plane where the pressure sensor 2, the first temperature sensor 3, the second temperature sensor 4, the first density sensor 5 and the second density sensor 6 is located and the upstream straight pipe section is greater than or equal to 10 times The diameter of the main air pipe 1; the distance between the plane where the pressure sensor 2, the first temperature sensor 3, the second temperature sensor 4, the first density sensor 5 and the second density sensor 6 is located and the downstream straight pipe section is greater than or equal to 5 times the diameter of the main air pipe 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com